Improve Service Life and Filtration Performance with Two-Step Filtration Concepts

Part II

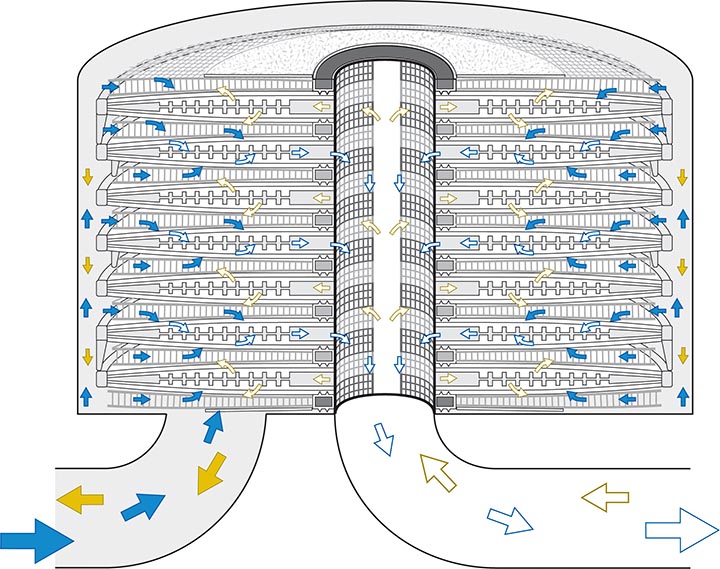

For more and more wine producers, stacked disc cartridges are becoming a real alternative to traditional sheet filtration solutions. In the first part of Eaton’s article series, it was shown that the use of backflushable, hermetically enclosed systems extend service life and enable a higher, more hygienic level of quality. These stacked disc cartridges are particularly robust because they contain an additional, honeycomb-structured polyester fabric between the filter cells. Buffers are formed between the filter cells, which separate them spatially and thus ensure that the filter cells remain stable and intact even during backflushing (Figure 1). Thanks to the backflush effect, both the amount of filtered wine and the service life can be significantly increased without risk of compromising the quality of the valuable wine ingredients. The tests described here also showed that the BECODISC® R+ backflushable stacked disc cartridges exceeded the service life of other backflushable stacked disc cartridges on the market by about 30%.

In the second part of the article series, we now look at how powerful the backflushable stacked disc cartridges with BECOPAD® premium cellulose sheets are and whether performance can be further optimized. For this purpose, both one- and two-step test series were conducted.

Field Test of One- and Two-step Filtration Concept with Stacked Disc Cartridges

With the aim of developing an optimized filtration concept with stacked disc cartridges for fine filtration prior to filtration before bottling using membrane filter cartridges, industry-related conditions were initially defined. Different national and international white wines should be filtered at a flow rate of 3,700 to 4,755 gal/h (14,000 to 18,000 l/h). The wines were first pre-filtered by means of tangential filtration. Fine filtration was subsequently carried out using the BECODISC R+ range backflushable stacked disc cartridges, before the filtered white wines were finally fed into storage tanks or to the bottling system.

In-line filtration, i.e., continuous filtration with fully automated cleaning and sterilization processes, is considered to be particularly important to optimize performance. During testing, the stacked disc cartridges were initially flushed back twice a week with warm water at 140°F (60°C) for 15 to 20 minutes. The entire system was then sterilized with sterile saturated steam for 20 minutes.

One-step Wine Filtration with Backflushable Stacked Disc Cartridges (field test 1)

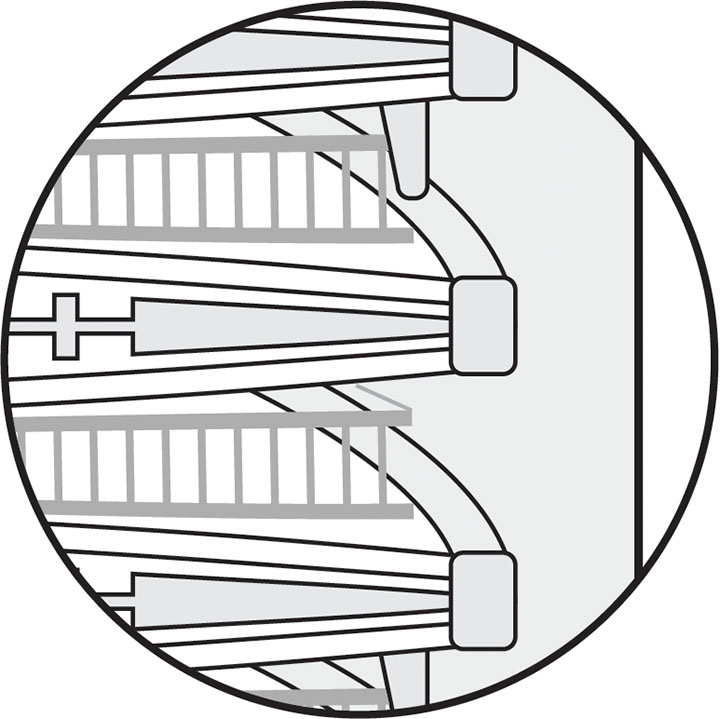

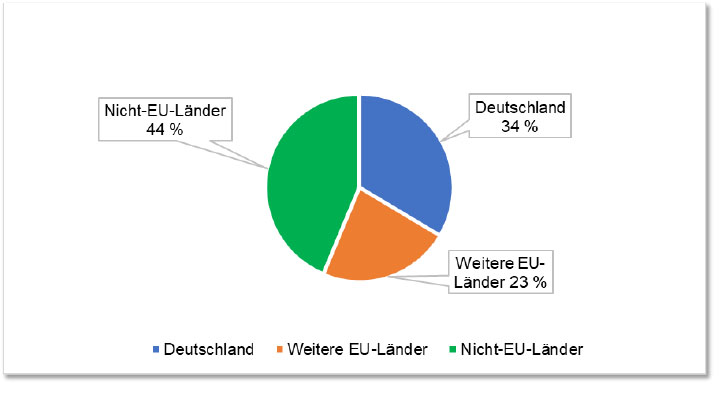

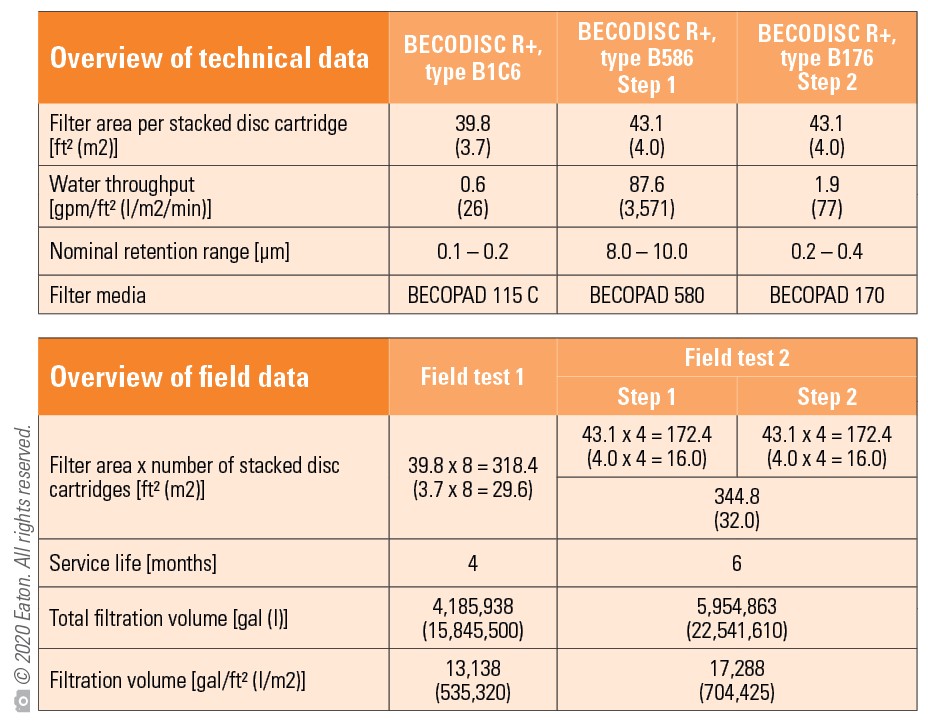

The first results were obtained using the BECODISC R+ (type B1C6) backflushable stacked disc cartridges with the BECOPAD Premium depth filter sheet for microbial removal (type 115 C) in a four-month study. A total of eight stacked disc cartridges were used. International white wines, 56% of which came from non-EU countries, 40% from Germany and 4% from other EU countries, were to be filtered (see Figure 2). The non-EU countries included Australia, Chile and New Zealand, while the other EU countries included Italy, France and Spain.

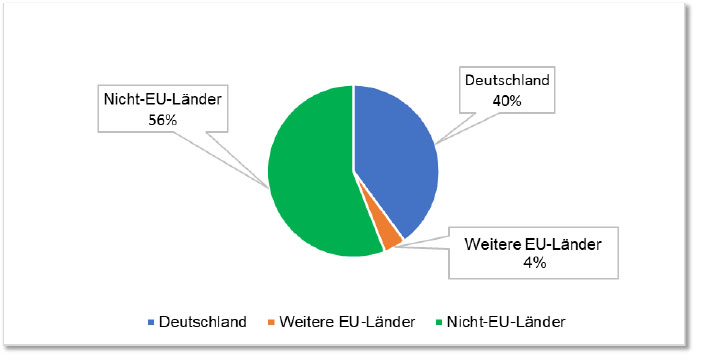

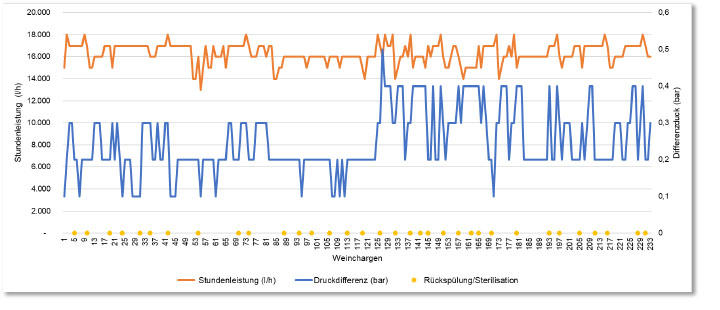

The flow velocity was between 3,700 to 4,755 gal/h (14,000 to 18,000 l/h). At a flow of 3,700 gal/h (14,000 l/h), this meant a filtration flux of 11.6 gal/ft²/h (472 l/m²/h), while at 4,755 gal/h (18,000 l/h) it meant a filtration flux of 14.9 gal/ft²/h (606 l/m²/h). The tests documented the differential pressure, the hourly output and the cleaning and sterilization process (see Figure 3).

Taking into account the differential pressure, it can be seen that the pressure in the first 125 lots has moved between psi 1.5 and 4.4 psi (0.1 and 0.3 bar). Between wine lots 80 to 125, the pressure fluctuated very consistently between 1.5 and 2.9 psi (0.1 and 0.2 bar). From wine number 125 onwards, a clear increase in pressure can be seen within a few lots. From the maximum pressure difference of 2.9 psi (0.2 bar) in almost 50 wine lots previously, this rose to psi 7.3 psi (0.5 bar) and did not fall below 2.9 psi (0.2 bar) again, despite the more frequent backflushes for cleaning. Up to around wine lot 150, the pressure difference could be maintained in the range between 2.9 and 5.8 psi (0.2 and 0.4 bar), but from batch 155 the highest value of the test was already measured at 10.2 psi (0.7 bar). Subsequently, the differential pressure no longer dropped below 4.4 psi (0.3 bar) and was subjected to large fluctuations of up to 5.8 psi (0.4 bar) between two cleanings. After around 165 lots and a total of 24 backflushes, the test was complete.

During the four-month practical test with the one-step filtration concept under industrial conditions, more than 4,185,938 gallons (15,845,500 liters) of wine were filtered through a total of eight BECODISC R+ B1C6 stacked disc cartridges. Converted to square meters, this results in a filtration volume of 13,138 gal/ft² (535,320 l/m²) with a filter area of 8 × 39.8 ft² (3.7 m²).

Two-step Wine Filtration with Backflushable Stacked Disc Cartridges (field test 2)

Due to the excellent filtration performance of the BECODISC R+ B1C6 stacked disc cartridges, the main focus was subsequently placed on extending the service life, which can improve most business key performance indicators. For this purpose, backflushable stacked disc cartridges with different separation areas were tested and adapted to the practical requirements. Fine filtration was the most promising due to a two-step depth filtration concept with a total of eight BECODISC R+ stacked disc cartridges. In the first step, four BECODISC R+ stacked disc cartridges (type B586) with BECOPAD 580 premium depth filter sheets were used for pre-filtration. In the second step, microbial removal filtration was carried out using four BECODISC R+ stacked disc cartridges (type B176) with BECOPAD 170 premium depth filter sheets.

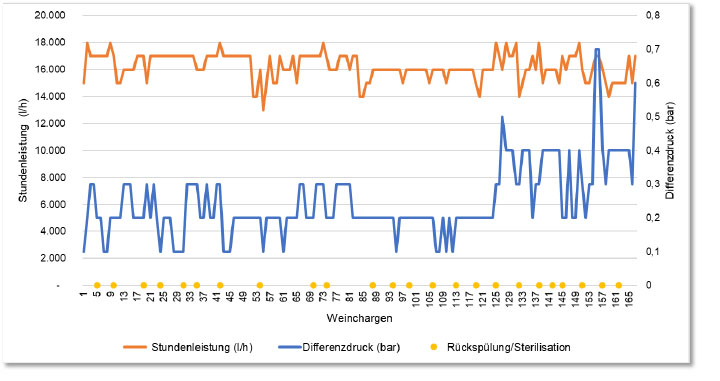

At a minimum flow velocity of 3,700 gal/h (14,000 l/h) to the BECODISC R+ type B176, the filtration flux is 10.7 gal/ft²/h (437 l/m²/h). At the maximum speed of 4,755 gal/h (18,000 l/h), it was just over 13.8 gal/ft²/h (563 l/m²/h). As in field test 1, the differential pressure, hourly output and cleaning and sterilization processes were determined and recorded.

Again, different national and international white wines were filtered at a flow velocity of 3,700 to 4,755 gal/h (14,000 to 18,000 l/h). 44% of the wine lots came from non-EU countries such as the USA, Chile, South Africa, Australia or New Zealand and 34% from Germany. Another 23% were from other EU countries such as Italy, France or Hungary (see Figure 4).

Once again, the differential pressure constantly moved between 1.5 and 4.4 psi (0.1 and 0.3 bar) for the first 126 batches (see Figure 5). Wine lot 127 caused a pressure difference of 7.3 psi (0.5 bar). Subsequently, backflushing was more frequent, and the pressure differences fluctuated between 2.9 and 5.8 psi (0.2 and 0.4 bar). So far, the results have been almost identical with the one-step tests with type B1C6 from the BECODISC R+ range.

The big difference, however, is the length of time for which this range, which is still profitable for wine production, can be maintained. While the one-step filtration process had to be completed after around 160 lots of wine and four months due to the increasing differential pressure and the fluctuations between the cleanings, two-step fine filtration can maintain the level from 2.9 and 5.8 psi (0.2 and 0.4 bar) until the end of the test after six months.

During the field test, the combination of the two BECODISC R+ stacked disc cartridges with graded separation areas was able to filter a total of 5,954,863 gal (22,541,610 liters) of wine. A total of 233 wine lots were filtered and 34 backflushes were carried out. Converted to square meters, with a filter area of 8 × 43.1 ft² (4 m²) for fine filtration, this results in a filtration volume of about 17,288 gal/ft² (704,425 l/m²).

Efficient Alternatives in Wine Filtration

In practice, wine filtration is dependent on many factors. Alongside product-specific factors, i.e., which wines with which properties are to be filtered, many technical factors also come into play. The choice of filtration technology – that is, traditional sheet filtration or modern stacked disc cartridge filtration – is fundamental. Once a technology has been chosen, it is important to consider what is most economical for the respective manufacturing process. The two field tests with international white wines have shown that filtration with backflushable stacked disc cartridges, such as those in the BECODISC R+ series, achieves a long service life.

The service life can be further extended if fine filtration is carried out in two steps. Here, of course, the correct grading in the optimal separation areas is important. In the two field tests, the change from one-step to two-step filtration concept clearly extended the service life and showed an increase in filtration volume. The filter area was increased from just under 323 to 344 ft² (30 to 32 m²) – an increase of around 6%. The service life could thus be extended from the original four months to the end of the test, i.e., to at least six months (66.6%). During this period, the total filtration volume was increased by around 1.8 million gallons (6.7 million liters).

As these results prove, BECODISC R+ backflushable stacked disc cartridges with BECOPAD Premium depth filter sheets are well suited for fine filtration of white wines, regardless of their origin. In addition, the field tests show that continuous, automated and – thanks to the enclosed system – particularly hygienic filtration of large quantities of wine is possible. Through regular backflushes, critical blocking can be avoided for a relatively long time. In the case of two-step filtration, this was actually until the end of testing – after six months and an impressive 5.9 million gallons (22.5 million liters) of filtered wine.

Both the one-step filtration with the BECODISC R+ type B1C6 microbial removal and the two-step concept of pre-filtration and microbial removal filtration with the BECODISC R+ types B586 and B176 showed impressive results. Wine producers who opt for fine filtration with stacked disc cartridges should take their individual requirements and options into account. The use of only one stacked disc cartridge can prove to be the most economical solution, especially for smaller and medium filtration quantities. For large filtration quantities over a long period of time, the two-step concept is likely to be the preferred choice.