As industries continually seek ways to streamline production processes and enhance product quality, automation emerges as a critical component in achieving these objectives. ELSNER stands at the forefront of automation, offering comprehensive solutions tailored to the spiral element and other filter element production sectors. With a focus on every step of the production process, from tape application to glue bead placement, ELSNER’s machinery is designed to elevate productivity and quality, providing manufacturers with the confidence they need in their investment.

Enhanced Productivity Through Automation

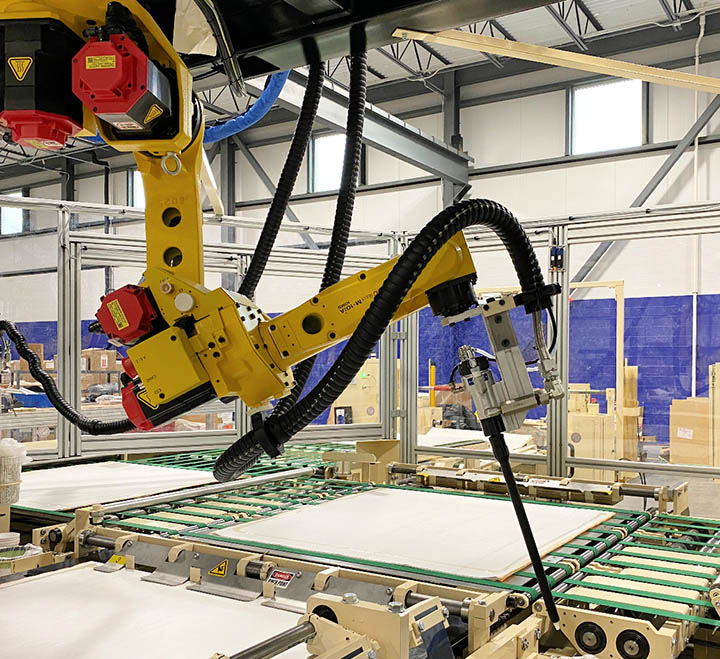

ELSNER’s commitment to innovation is evident in its line of automated machinery, which addresses the entire spectrum of the spiral element and other filter element production. This range of equipment is not just about speeding up production times; it’s about redefining what’s possible in terms of efficiency and output quality. By integrating automated solutions like the EMF-42 for automatic membrane folding and the APB-42 for filter assembly and rolling, ELSNER enables manufacturers to reduce the margin for human error significantly. This precision ensures products of consistently high quality, with the added benefits of increased production uniformity and accuracy.

Revolutionizing Workflows and Saving Resources

In the face of labor shortages, automation has become a strategic advantage and necessity. ELSNER’s machinery, including the innovative SFR-42 for filter rolling and gluing, offers a way forward. By automating complex and repetitive tasks, companies can maintain operations with fewer employees, allowing them to redeploy human resources to more critical, skill-intensive areas of the production process. This not only optimizes productivity but also opens avenues for employee growth and skill development within the organization.

Comprehensive Solutions for Spiral Element and Other Filter Element Production

ELSNER Engineering Works provides a comprehensive approach to automation in spiral element and other filter element production. Their solutions cover:

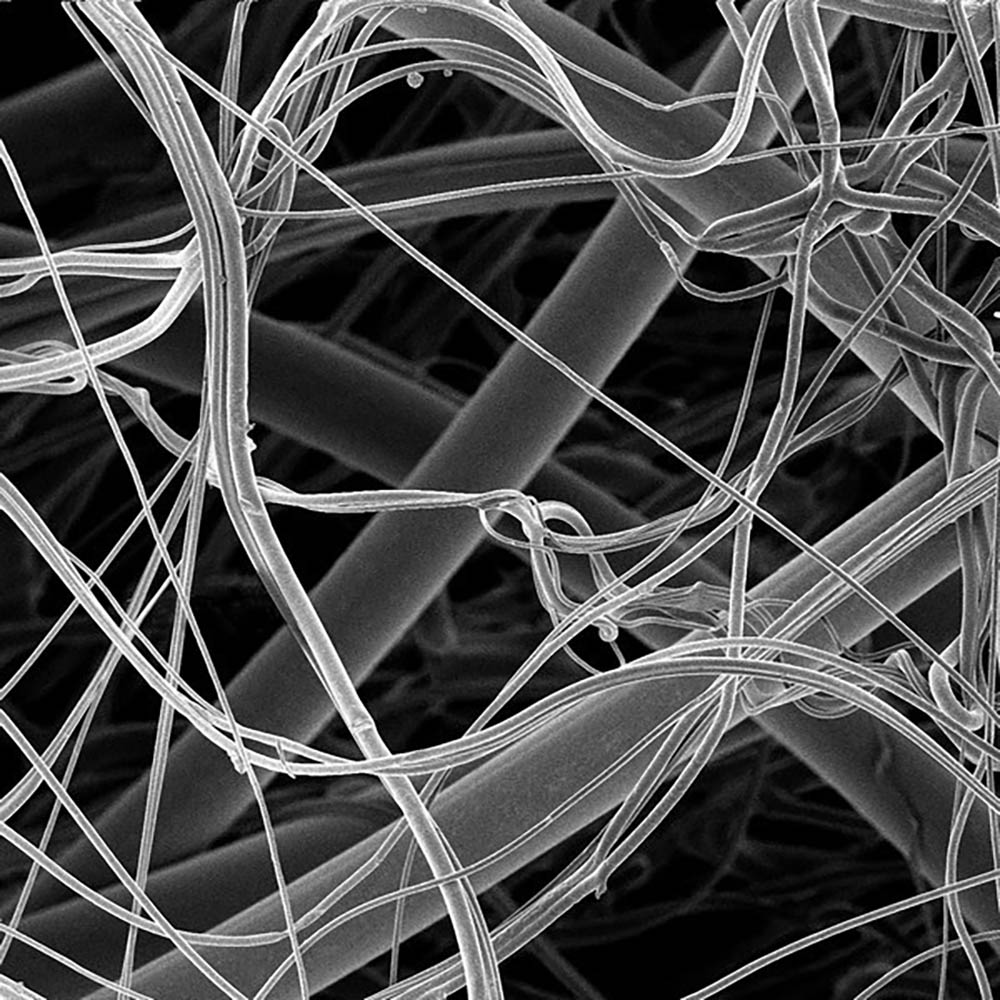

Automatic Membrane Folding: The EMF-42 machine transforms membrane and plastic mesh into precisely folded “leaves,” streamlining the production process.

Filter Assembly and Rolling: The APB-42 automates the assembly of filter components, enhancing efficiency and consistency.

Filter Rolling and Gluing: With the SFR-42, tasks such as applying glue and outer wrap tape for spiral wound membrane filters are automated, minimizing manual labor and improving throughput.

Filter Element Finishing: The Element Trim Saw is meticulously designed for finishing the edges of industrial liquid filtration elements, ensuring a flawless final product.

ELSNER Engineering’s global footprint, with over 3000 machines operating across 60 countries, underscores its reputation as a leader in automation solutions for the filtration industry. By embracing ELSNER’s technologies, companies can meet and exceed their customers’ growing demands, setting new standards for productivity and quality in the manufacturing world.

Email: eew@elsnereng.com