Epic Resins Adds a Resilient Line of Molded End Cap Polyurethanes

Epic Resins is committed to serving global customers as a trusted partner in superior quality resins and polymers. Their philosophy is based on listening to your needs and developing quality solutions to meet your challenges. The company was built on technology-proven chemistry and a wealth of market and

application knowledge. This guarantees consistent products and maximum value.

Founded and headquartered in Wisconsin for 65 years, Epic Resins has formulated, manufactured and supplied high-quality epoxy resins and polyurethanes to a wide range of industries. Specializing in potting and encapsulation compounds and adhesives, Epic Resins delivers products to enhance customer profitability and performance.

Because Your Design Can NOT Be Compromised

Whether you’re a spa equipment supplier wanting a filter end cap material, an OEM supplier seeking an air filter potting compound or an automotive manufacturer looking for a chemical resistant filter adhesive, Epic Resins can formulate it.

Epic Resins, a renowned manufacturer of epoxy resin and polyurethane products, answers the needs of the filtration market with their ToughPleat series. This line of molded end cap polyurethanes boasts exceptional performance and versatility.

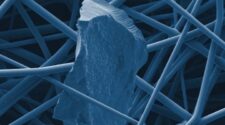

The ToughPleat series is comprised of a range of two-component polyurethane formulations specifically developed for molded end caps. These VOC-free polyurethanes are engineered to possess outstanding tear resistance and high strength, making them ideal for demanding applications in molded filter end caps. Common uses of the material include bag house filters and high-temperature, under-the-hood automotive applications.

User-Friendly Features

The material’s robust yet flexible nature makes it particularly well-suited for filters that are subjected to constant pulsing and/or pressure drops. By providing superior tear resistance, ToughPleat ensures that filters remain undamaged during the installation or removal process. Its high tensile strength and elongation properties ensure durability and longevity, even under demanding conditions.

One of the standout features of this series is its user-friendly composition. With a convenient mix ratio by volume and low viscosity, these polyurethanes can be easily dispensed and seamlessly integrated with various types of metering equipment.

Enhance Productivity & Cost Savings

ToughPleat’s fast gel time guarantees quick turnover of filters and production cycles. The overall efficiency of the manufacturing process reduces work-in-progress (WIP) time in many production configurations. This efficiency boost translates into enhanced productivity and cost savings for manufacturers.

Multiple Versions Available

Each filter application has its own set of unique requirements. To address this, the ToughPleat series offers multiple versions tailored to specific property needs. Filled and unfilled versions of the material with a mixed color of black or gray are available with property versions that vary based on:

- Hardness

- Tensile strength

- Elongation

- Tensile modulus

- Tear strength

ToughPleat benefits for molded end cap applications:

- High tensile strength

- High elongation

- Excellent tear resistance

- Easy to dispense

- Reduced WIP time