Nanotechnology’s Promise for Cleaner Indoor Air and Beyond

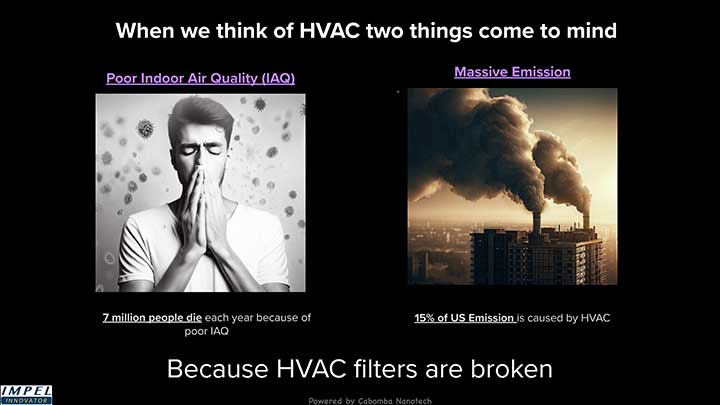

In an era where indoor air quality has become a paramount concern, the limitations of traditional HVAC filtration systems are increasingly apparent. From the rise in airborne pollutants to the emergence of new pathogens, our indoor environments face unprecedented challenges. This article explores the current state of HVAC filtration, its shortcomings, and how cutting-edge nanotechnology offers a promising solution for creating healthier indoor spaces while addressing energy efficiency concerns. Moreover, we’ll examine how these challenges extend to other fluid filtration domains, such as water and dairy processing.

The Current State of HVAC Filtration

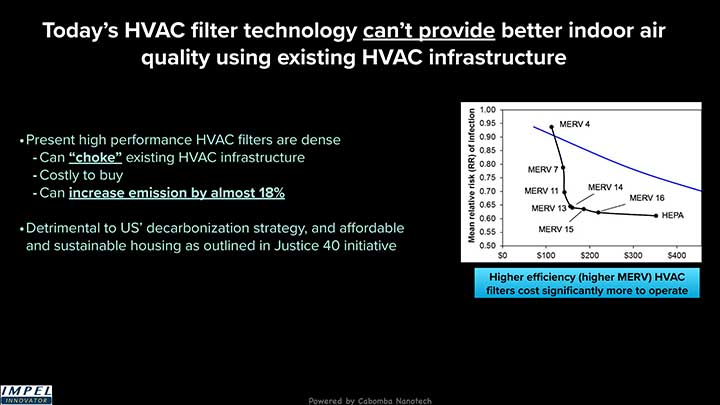

HVAC systems play a crucial role in maintaining comfortable and healthy indoor environments. However, conventional filtration methods often struggle to keep pace with evolving air quality demands. Most current HVAC filters rely on mechanical filtration, where airborne particles are captured as air passes through a mesh of fibers. The effectiveness of these filters is typically measured by the Minimum Efficiency Reporting Value (MERV) rating system (ASHRAE, 2017). While higher MERV ratings indicate better filtration, they come with significant drawbacks:

- Increased Energy Consumption: Higher-rated filters often create more airflow resistance, forcing HVAC systems to work harder and consume more energy (Stephens et al., 2010).

- Reduced System Efficiency: The increased strain on HVAC systems can lead to decreased overall efficiency and potentially shorter equipment lifespan (Zaatari et al., 2014).

- Limited Capture of Ultrafine Particles: Even high-MERV filters struggle to effectively capture particles smaller than 0.3 microns, which include many harmful pollutants and pathogens (Kim et

al., 2016). - Inconsistent Performance: Filter efficiency can decrease over time as particles accumulate, leading to inconsistent air quality (Azimi et al., 2014).

Modern Indoor Environments

Several factors contribute to the growing complexity of maintaining indoor air quality:

- Urban Air Pollution: Increasing urbanization has led to higher levels of outdoor pollutants infiltrating indoor spaces (World Health Organization, 2021).

- Wildfires and Natural Disasters: Recent years have seen a rise in wildfires, introducing smoke and ultrafine particles that challenge traditional filtration methods (Fisk & Chan, 2017).

- Emerging Pathogens: The COVID-19 pandemic highlighted the importance of filtration in reducing airborne disease transmission (Morawska et al., 2020).

- Energy Efficiency Mandates: Stricter energy efficiency regulations require HVAC systems to perform better while consuming less power (U.S. Department of Energy, 2022).

- Indoor Chemical Pollutants: Modern building materials and consumer products can release volatile organic compounds (VOCs) that are difficult to filter (Salthammer et al., 2018).

The Promise of Nanotechnology in HVAC Filtration

As traditional filtration methods reach their limits, nanotechnology emerges as a promising solution. Nanotech-based filtration systems offer several advantages over conventional methods:

- Enhanced Particle Capture: Nanofibers and nanostructured materials can create filters with much higher surface area-to-volume ratios, dramatically increasing particle capture efficiency (Wang & Pui, 2018).

- Lower Pressure Drop: Despite their high efficiency, nanotech filters can maintain lower pressure drops, reducing the energy demand on HVAC systems (Balgis et al., 2016).

- Selective Filtration: Some nanomaterials can be engineered to target specific pollutants or pathogens, offering more precise air purification (Yousefi et al., 2019).

- Self-Cleaning Properties: Certain nanocoatings can provide self-cleaning or antimicrobial properties, extending filter life and maintaining consistent performance (Xu et al., 2018).

Recent Nanotech Filtration Advancements

Research in nanotech filtration has yielded exciting developments:

- Molecular Force-based Filtration: Some innovative companies are developing filters that utilize molecular forces to capture particles. This approach allows for highly efficient filtration of even the smallest contaminants, including individual virus particles, while maintaining low energy demand (Liu et al., 2021).

- Carbon Nanotubes: Filters incorporating carbon nanotubes have shown promise in capturing ultrafine particles and VOCs with minimal pressure drop (Das et al., 2019).

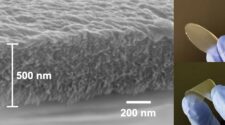

- Nanofiber Membranes: Electrospun nanofiber membranes offer high filtration efficiency for particles as small as 100 nanometers while maintaining good air permeability (Zhang et al., 2020).

- Photocatalytic Nanomaterials: Titanium dioxide nanoparticles can break down organic pollutants and inactivate microorganisms when exposed to light, offering both filtration and purification (Schneider et al., 2014).

Case Studies and Research Data

Several studies have demonstrated the potential of nanotech filtration:

- A 2020 study published in the Journal of Nanoparticle Research found that nanofiber filters achieved 99.99% filtration efficiency for particles as small as 100 nm, while maintaining a pressure drop 20% lower than commercial HEPA filters (Kim et al., 2020).

- Research conducted at the University of California, Riverside, showed that carbon nanotube filters could remove up to 90% of VOCs from indoor air, outperforming activated carbon filters (Megri & Haghighat, 2018).

- A pilot study in a hospital setting found that HVAC systems equipped with nanotech filters reduced airborne bacterial counts by 98% compared to traditional filters, while consuming 30% less energy (Li et al., 2019).

Challenges Beyond HVAC

Let’s look at filtration in other fluid systems. It’s important to note that the fundamental challenges faced in HVAC filtration extend to other fluid filtration domains as well. Industries such as water treatment, dairy processing, and pharmaceutical manufacturing face similar issues:

- Energy Consumption: High-efficiency filters in water treatment plants and dairy processing facilities often require significant energy input, leading to increased operational costs (Mazille et al., 2015).

- Particle Size Range: Like air filtration, water and dairy filtration systems struggle with capturing a wide range of particle sizes, from large sediments to microscopic contaminants (Guo et al., 2018).

- Fouling and Efficiency Loss: Membranes and filters in liquid filtration

systems are prone to fouling, which reduces efficiency over time and necessitates frequent cleaning or replacement (Huang et al., 2017). - Chemical Resistance: Filters in industrial processes must withstand various chemicals and pH levels, a challenge that nanotechnology can potentially address (Wu et al., 2020).

Nanotechnology Solution

As indoor air quality concerns continue to grow, the limitations of traditional HVAC filtration become increasingly apparent. These challenges, however, are not unique to air filtration but extend across various fluid filtration applications. Nanotechnology offers a promising path forward, with the potential to dramatically improve filtration efficiency while reducing energy consumption across multiple industries.

At Cabomba, we have developed a revolutionary nanofilter platform that addresses these challenges head-on. Our technology has the potential to save 50-80% of energy demand for all kinds of filtration processes, from HVAC systems to water treatment and industrial fluid processing. By utilizing advanced nanostructures and molecular forces, our filters achieve superior capture efficiency for a wide range of contaminants while maintaining remarkably low pressure drops.

Our product can create a future, where HVAC can provide air that is at-par or cleaner than air purifiers and can dramatically reduce the energy demand. All of this can be achieved without any capital cost, using legacy hardware.

As research progresses and these technologies mature, we can look forward to not only cleaner indoor air but also more efficient and effective filtration across various industries. The challenge now lies in bridging the gap between laboratory successes and widespread commercial application, a task that will require collaboration between researchers, manufacturers, and policymakers.

With continued investment and innovation in this field, nanotechnology could revolutionize how we approach filtration in all its forms. The potential benefits extend far beyond improved air quality, encompassing significant advancements in water purification, food processing, and industrial fluid handling. As companies like Cabomba continue to push the boundaries of what’s possible with nanotech filtration, to disrupt 500 billion dollar of legacy industries with the potential to reduce carbon emission by gigaton, we move closer to a future where clean air and water are more accessible and sustainable than ever before.

![Figure 1: Differentiation with membranes based on the famous Robeson diagram that plots selectivity vs. permeability. From Reference. [4]](https://www.filtnews.com/wp-content/uploads/IFN_042023_membranes_Figure1-225x125.jpg)