Recent advancements in material science have facilitated the development of flexible ceramic microfiber non-woven material, representing a significant innovation that combines the high-temperature stability and chemical resistance of ceramics with the flexibility and processability characteristic of non-woven material. This material can function either as standalone filtration media or, more significantly, as performance-enhancing layers within multi-layer filtration systems, potentially improving separation efficiency and system durability.

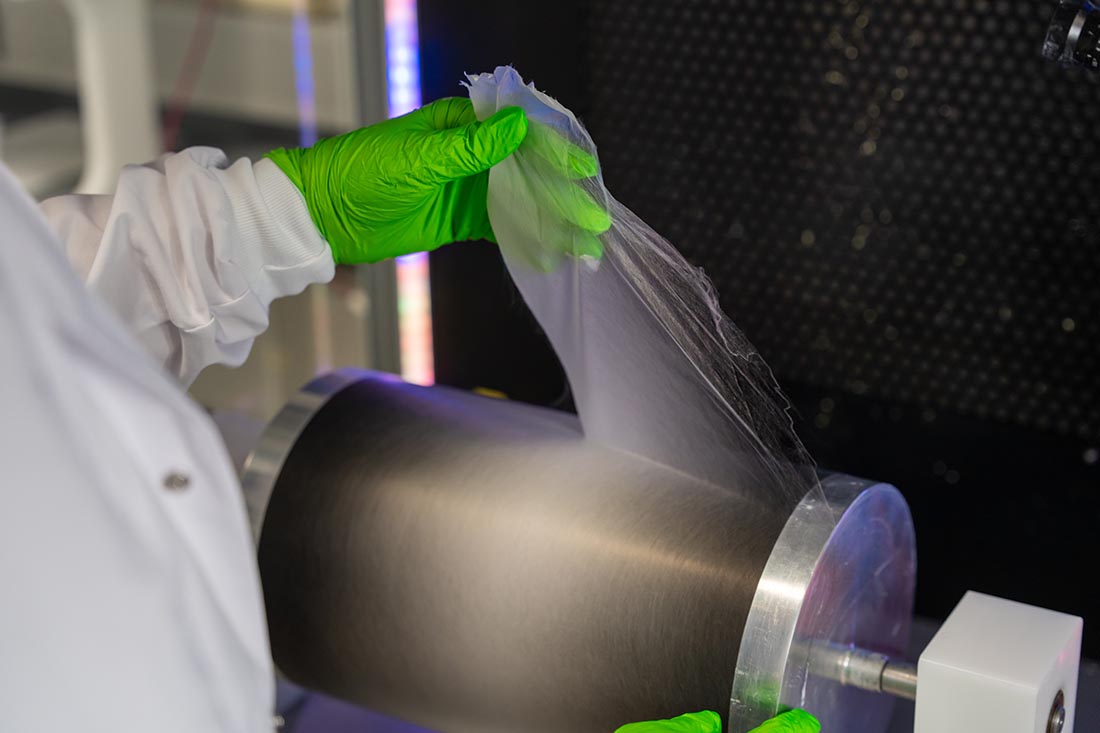

Key characteristics include a highly porous structure (>90%) and an ultrathin profile (130 micron), which enable efficient filtration with minimal pressure drop. The narrow pore size distribution improves the capture of fine particulates, making this material suitable for specific filtration applications. Their flexibility allows for processing into pleatable, complex shapes, ideal for space-constrained environments and low-pressure filtration systems.

The material exhibits high thermal stability, enabling reliable operation at temperatures up to 800°C without compromising structural integrity, while its chemical resistance enhances functionality in demanding environments, such as hot gas filtration, mist filtration, and aggressive gas separation. Additionally, the surface properties can be tailored through the application of sizing agents, allowing for targeted modifications to optimize performance when integrated as functional layers within comprehensive filtration systems.

The potential for catalytic coatings further extends the applicability of this material in scenarios where filtration and catalytic action are both required, for example in process filtration and industrial furnaces. This adaptability, combined with the ability to modify key parameters such as pore size and surface characteristics, positions the material as a versatile, high-performance component across various filtration contexts.

By integrating flexibility, high porosity, thermal resilience, and options for surface modification, this ceramic microfiber nonwoven material establishes a highly adaptable platform for advanced filtration systems. With its unique properties, this material is a promising candidate for enhancing existing filtration solutions, particularly in high-temperature environments that demand customized filtration performance.