Nitto Denko Corporation’s TEMISH engineered porous PTFE membrane has applications ranging from ULPA and HEPA clean rooms to industrial uses, such as dust collection in power plants and protection for offshore gas turbines. A huge additional market is in often tiny high-performance filters as venting materials for many consumer devices.

No compromise

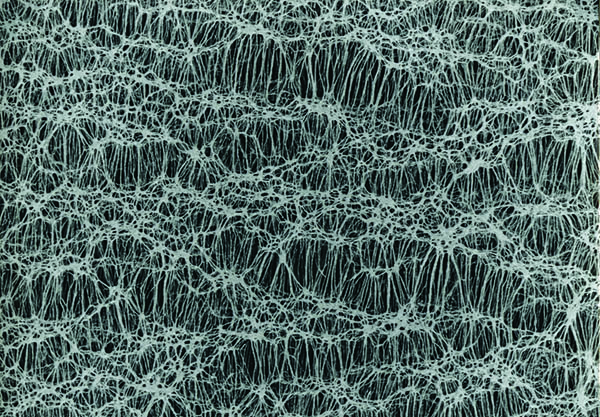

The water repellency of PTFE and its three-dimensional network structure of ultra-fine, nanofibers ensure TEMISH is waterproof and dustproof, with high breathability.

High air permeability results from the millions of micropores per square centimeter of the filter. Air permeability is dependent on the pore size, thickness, and porosity of the membrane, all of which also influence water resistance and dust collection capacity.

Generally, a higher air permeability tends to lower both water resistance and dust collection efficiency, but this compromise is overcome as a result of the unique and proprietary technology with which the TEMISH is produced.

“The PTFE is extruded and calendered, and then either sintered or stretched out to 3-4,000 times its original size in our proprietary processes, depending on the application,” explains Brett L. Herrick senior manager of business development for the Americas Growth Division of Nitto, Inc., headquartered in Teaneck, New Jersey. “It is then laminated or further processed with nonwovens, woven fabrics, glass fiber sheets, elastomers or molded plastics. Air goes straight through the membrane, but water won’t.”

Clean rooms

In clean rooms, up to 99.99% filtration efficiency is achievable with TEMISH, and the technology’s extremely low pressure drop lowers lifecycle costs. In addition, the inert nature of PTFE means it does not generate harmful off-gases or shed fibers, and it has excellent chemical resistance against acids, alkalis, and organic solvents.

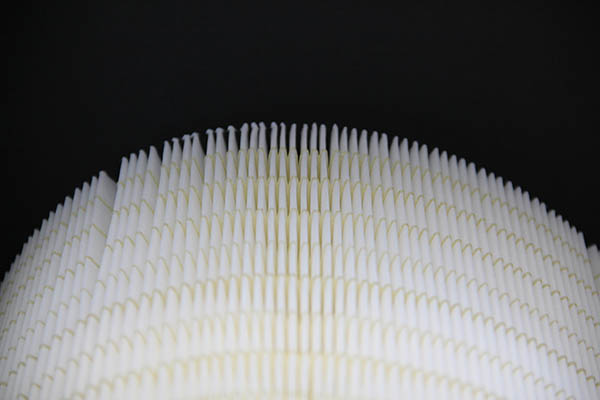

For HEPA-grade performance, the TEMISH membrane is generally sandwiched between two spunbonded nonwovens or can be laminated to a thicker thermally bonded nonwoven. For ULPA grades, a five-layer construction of two TEMISH membranes between layers of 30 GSM spunbond can be employed.

TEMISH ULPA and HEPA grades are also used in many consumer applications, and over the past year, there has naturally been intense interest in their performance in N95 respirators.

High-grade powered air purifying respirators (PAPRs), for example, work with a battery motor and here, the TEMISH membrane allows air to pass through it with no drain on the battery, in a much more compact form than is possible with competing materials of the same surface area.

Dust collection

In dust collection applications, TEMISH is generally laminated to a nonwoven or woven base material in a two-layer structure depending on the specific environment, temperature and the dust being collected.

Extremely high dust release is achieved via vibration or pulse clearing techniques, with the durability and regenerating properties of these materials ensuring low life cycle costs in factory and incineration applications.

Venting

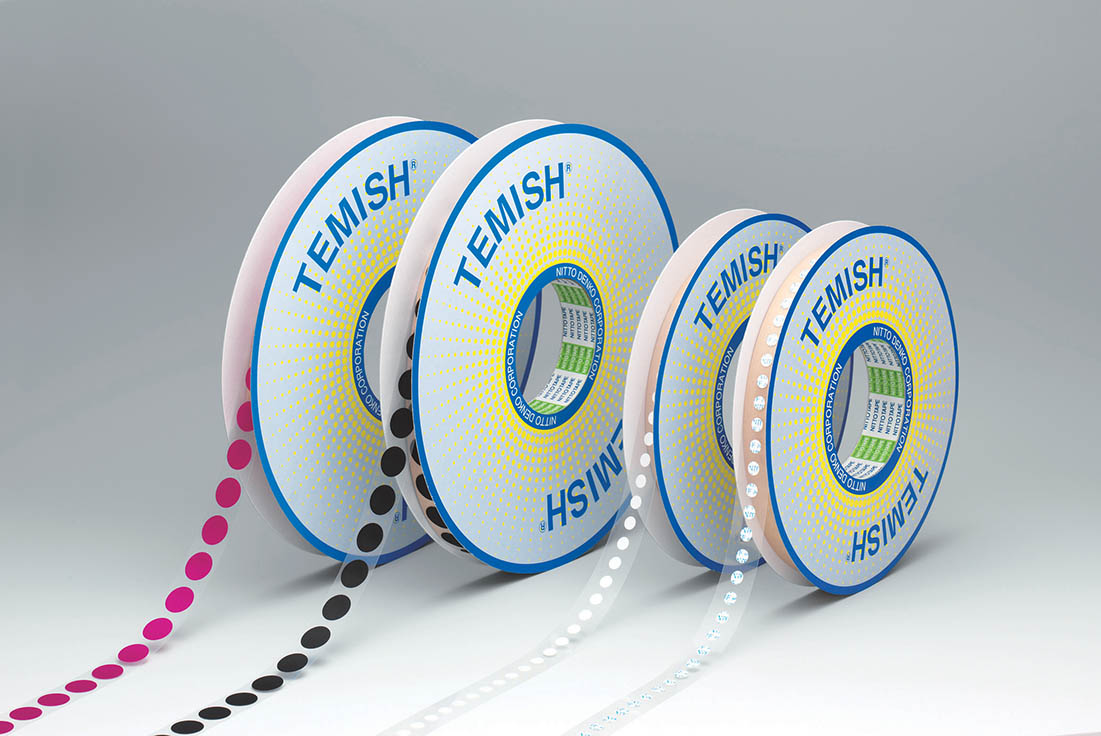

Vent filters, supplied in sheets or on reels, can be found in everything from automotive headlamps and electrical control units to consumer appliances such as mobile phones, cameras, device control panels, electric toothbrushes, and printer cartridges.

In these products they are providing the essential resistance to water and dust to prevent any damage and also regulating the differential pressure between the inside of the device and outside elements.

These tiny, but crucial filters are laminated to polyester nets or nonwovens in thicknesses of between 0.1 to 0.3mm.