One aspect of my position as the Director of Education & Technical Affairs at INDA is the responsibility of evaluating the educational and work force development needs of the nonwovens industry. INDA provides a number of courses and workshops ranging from an Elementary Nonwovens course – a short introduction to nonwovens, an Intermediate Nonwovens – a more involved course which includes deconstruction and reverse engineering of nonwoven using products, and courses with greater depth on specific nonwoven technology topic areas such as spunbond/meltblown nonwovens, fibers and filaments, fabric design and characterization, and product development. Additionally, INDA provides courses that focus on specific nonwoven end-uses such as wipes, absorbent hygiene, and filtration/filter media. In considering the course on filter media it is important to understand how it fits within the broader space of educational offerings provided for HVAC, filtration, and separation industries and what unmet needs it should address.

In North America there are a number of organizations and groups that provide training related to filtration and separation including ASHRAE, NAFA, AFS, WFI, NWI, and INDA. There is some overlap between the offerings each provides, but each addresses different educational and certification needs.

ASHRAE® (www.ashrae.org/professional-development) for instance, has built a portfolio of educational offerings to support HVAC professionals designing, installing, and operating HVAC systems, including in-depth understanding of all components of such systems and sub-systems. Additionally, they provide resources for understanding and properly implementing relevant standards for air quality. Many of their ASHRAE Learning Institute courses are accepted for continuing education credits by individual states, the American Institute of Architects, the Green Building Certification Institute, and other credentialing organizations.

The National Air Filtration Association® provides a range of educational offerings that support air filtration specialists: NAFA Certified Air Filter Specialist and NAFA Certified Technicians, Level I and Level II. These certifications address when a clear and up-to-date knowledge of air filtration products and technologies is needed (www.nafahq.org/afspecialist/#). Certification examinations are conducted in-person at NAFA events throughout the year and virtually. Learning is largely self-directed with periodic opportunities for virtual Q&A/Tutorials.

A required resource for achieving certifications is a strong working knowledge of the NAFA Guide to Air Filtration (www.nafahq.org/publications/). Regardless of whether one is pursuing a NAFA certification, this guidebook is an indispensable resource and is highly recommended to anyone new to the industry. It covers principles of air filtration, filter types, air cleaners, filter testing, clean rooms, airborne contaminants and micro-organisms, air cleaning for industrial applications, and applications of various ASTM, ANSI, and ISO standards.

The American Filtration & Separations Society also provides a program to become an AFS Certified Professional (afss.mclms.net) which recognizes individuals with a combination of education, training, and experience in filtration and separation technologies. There are three main components to the exam-verified training requirement: liquid/solid separations, air/gas filtration, and filter media.

The courses are provided both in-person at AFS events and virtually. I recently had the opportunity to audit the full solid/liquid separation course at FiltCon 2023. INDA has historically had far greater focus on air/gas filtration and filter media than solid/liquid separation processes. Thus, I attended this course with decidedly limited background in this area. The course was broken into four sections, each section was taught by a recognized expert, with a rich history in both service and education from the industry. The course was designed to focus primarily on conceptual understanding rather than mathematical modelling of filtration and separation processes.

In North America there are a number of organizations and groups that provide training related to filtration and separation including ASHRAE, NAFA, AFS, WFI, NWI, and INDA.

A question that is always asked in evaluating training courses is whether the student anticipated being able to apply the knowledge gained. In my case, the knowledge gained during the eight-hour course immediately jumpstarted my understanding and appreciation of the subsequent two days of technical presentations at FiltCon. While not planned, the fortuitous combination of the training course and attending the technical seminars proved beneficial and is an approach worth considering when available at events like FiltCon.

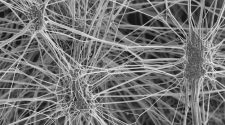

The Waterloo Filtration Institute has designed a Certified Filtration & Separation Specialist program that entails a comprehensive coverage of air and liquid filtration that ranges from fundamental principles to sophisticated technologies, contemporary challenges, novel opportunities, and up-to-date market trends. The content is provided via more than twenty virtually delivered two-hour modules (www.wfinstitute.com/wfi-online-courses). More than half of the modules are focused on in-depth treatment of specific technology and end-use applications such as nanofibers in filtration, engine intake and cabin air filtration, and membranes in filtration amongst others. WFI’s courses are taught by leading members of industry, testing labs, and academia. WFI’s courses are the only ones that are provided entirely virtually, and they are augmented with open-door “Filtration Hour” virtual panel sessions and capstone virtual conferences for Innovative Clean Air Solutions and Innovative Clean Water Solutions.

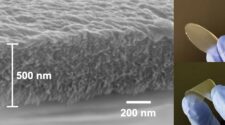

The Nonwovens Institute at North Carolina State University, a frequent education collaborator with INDA, has made available pandemic response focused modules on N95 and Surgical Masks, Air & Aerosol Filtration, Meltblown Fabrics for PPE, Spunbond Fabrics for PPE, and testing of both N95 Masks and Surgical Masks (https://thenonwovensinstitute.com/workforce-development/#course00). Additionally, Dr. Pourdeyhimi and colleagues regularly provide customized courses pertaining to filtration topics.

Both INDA and EDANA, trade associations of the nonwovens industry, also provide workforce development resources. In both cases, the primary focus is on filtration media. For those in

Europe, EDANA (www.edana.org/trainings/filtration-training/fundamentals-in-filtration) provides a two day, in-person training course providing a broad coverage of air filtration technologies and filter media, with particular focus on nonwoven materials used.

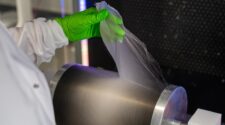

INDA conducted their two-day long Filter Media course in conjunction with FiltXPO – last October in Chicago, IL (www.filtxpo.com/training.html). The course included elements of air/gas filtration, solid/liquid separation, and a heavy emphasis on filter media design, choice, and performance. This course was taught by Dr. Pourdeyhimi and colleagues from The Nonwovens Institute. The choice to focus on filter media rather than filter and filtration system design was informed by the review of existing filtration training options. Also at FiltXPO, there were two days of technical seminars co-organized by Dr. Christine Sun of the Waterloo Filtration Institute and INDA.

Regardless of one’s needs or one’s place within the filtration value chain, there are appropriate technical education opportunities available to support career growth and technical understanding.