Ushering in a huge new opportunity for advanced filtration, on August 11th this year, the U.S. Department of Energy (DOE) announced up to $1.2 billion in funding to advance the development of two commercial-scale direct air capture (DAC) facilities in Louisiana and Texas.

DAC Hubs

The two projects announced by the DOE – the first on such a scale in the United States –represent the initial selections from the President’s DAC Hubs program aiming to kickstart a nationwide network of large-scale carbon removal sites to address legacy carbon dioxide (CO2) pollution and complement rapid emissions reductions.

These emissions are already in the atmosphere, fueling climate change and extreme weather and jeopardizing public health and ecosystems across the globe.

Together, the two projects are expected to remove more than two million metric tons of CO2 emissions each year from the atmosphere once fully scaled – an amount equivalent to the annual emissions from roughly 445,000 gasoline-powered cars – and create 4,800 good-paying jobs in Louisiana and Texas.

Transformational

“Cutting back on our carbon emissions alone won’t reverse the growing impacts of climate change – we also need to remove the CO2 that we’ve already put in the atmosphere which nearly every climate model makes clear is essential to achieving a net-zero global economy by 2050,” said U.S. Secretary of Energy Jennifer M. Granholm. “With this once-in-a-generation investment made possible by President Biden’s Investing in America agenda, the DOE is laying the foundation for a DAC industry crucial to tackling climate change – transforming local economies and delivering healthier communities along the way.”

The DOE estimates that reaching President Biden’s plan for a net-zero emissions economy will require between 400 million and 1.8 billion metric tons of CO2 to be filtered from the atmosphere and captured from emissions sources annually by 2050.

Technology

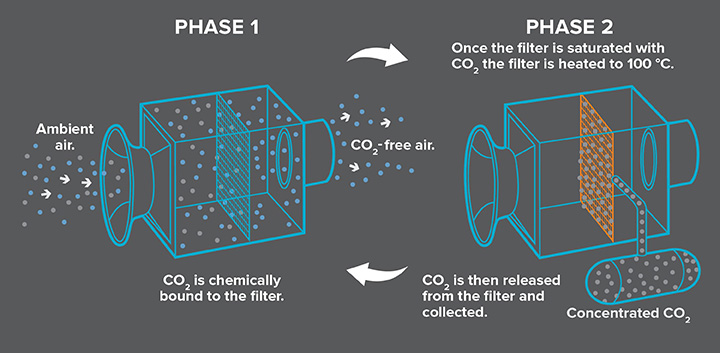

There are a number of different DAC technologies for filtering CO2 from the air by either absorption or adsorption techniques using common chemicals which are already in use in other applications, notably water and gas filtration. These include liquid amine solutions and amine-functionalized sorbents, while MOFs (metal organic frameworks) now show the most promise for the future.

MOFs are materials composed of metal ions and organic ligands that form a three-dimensional structure with a high surface area and well-defined pore size and porosity. These properties make MOFs ideal for gas storage and separation, including carbon capture.

Adsorption technology is considered a promising alternative to replace typical absorption methods based on liquid amines in carbon capture due to the simplicity of the process, mild operating conditions, flexibility during operation, low operating cost and no corrosion in equipment. Adsorption technologies are also favored for CO2 capture in post-combustion conditions such as low pressure, mild temperatures and low carbon dioxide concentration, where implementing absorption techniques results in higher operating costs.

Sequestration

Once the CO2 is captured from the atmosphere, heat is typically applied to release it from the filters. The captured CO2 can then be injected deep underground for sequestration in certain geologic formations or used in various products and applications. To maximize climate benefit, most captured CO2 would need to go to vast and permanent underground sequestration rather than useful but more limited utilization routes.

Companies with the most developed DAC technologies today include Climeworks, headquartered in Zurich, Switzerland, Canada’s Carbon Engineering and Global Thermostat, of Brighton, Colorado.

The DOE estimates that reaching President Biden’s plan for a net-zero emissions economy will require between 400 million and 1.8 billion metric tons of CO2 to be removed from the atmosphere and captured from emissions sources annually by 2050.

Momentum

The momentum of DAC in the USA doesn’t stop with the two projects – to assess the viability of future DAC Hub demonstrations, the DOE also announced 19 additional projects selected for award negotiations that will support earlier stages of project development, including feasibility assessments and front-end engineering and design studies. On August 22, the DOE announced a further $12.5 million in funding for Los Angeles-based CarbonCapture and a team of strategic partners to develop a 20,000-ton DAC Hub in Southwest Wyoming, with further projects still to be announced.

Louisiana Hub

The initial two DAC Hubs selected for award negotiations will help further demonstrate the ability to capture and store atmospheric CO2 at scale.

The first, Project Cypress, is to be located in Calcasieu Parish, Louisiana, and involves Battelle, a private non-profit applied science and technology development company headquartered in Columbus, Ohio, working in coordination with Climeworks Corporation, and Heirloom Carbon Technologies, which is currently operating a small DAC facility in Brisbane, California. In a first-of-its-kind project, the CO2 captured by the Brisbane plant has already been permanently embedded in concrete used in building projects in the Bay Area, by partner CarbonCure.

The Louisiana Hub will rely on Gulf Coast sequestration for offtake and geologic storage of the captured atmospheric CO2.

Orca

In 2021 Climeworks launched Orca in Iceland as the world’s largest direct air capture and storage (DAC+S) plant to date.

The facility consists of eight collector and filtration containers, each with an annual capture capacity of 500 tons. The containers are arranged around a central process hall that accommodates all electrics, such as the processing unit, allowing the company to remotely operate and control the facility.

Construction of a second and larger plant in Iceland – Mammoth, with a planned capacity of 36,000 tons per year – is now in progress.

Benefits

The key benefits of DAC according to Climeworks, are that it is location-independent, highly scalable and measurable and enables efficient land usage.

CO2 is in the air at the same concentration everywhere in the world which means that DAC plants can be located anywhere as they do not need to be attached to an emissions source. They are only required to be placed near a renewable energy source and in a place where CO2 can be stored.

Climeworks plants are based on a modular technology design, making them highly scalable and require less land than other techniques. The planting of trees is the most obvious and natural way of absorbing carbon, but on a land area of 0.42 acres, the Orca plant can remove 4,000 tons of CO2 from the air every year – almost 1,000 times more effective than trees. The same land would host around 220 trees with an estimated capacity of 22kg each – only 4.62 tons of CO2 per year.

Storage

The company further points out that DAC+S is often confused with carbon capture and storage (CCS), but the two are very different. CCS captures CO2 emissions at a point source, for example, a smokestack at a power plant where the aim is to offset carbon emissions as they’re being released into the atmosphere. DAC+S works instead to remove unavoidable and historic CO2 emissions already released into the atmosphere.

At the Orca plant in Iceland, the geological storage of CO2 is handled by partner Carbfix by being first dissolved in water before it’s injected into the sub-surface, where it reacts with the rock to form solid carbonate minerals.

Texas Hub

The South Texas DAC Hub is being sited in Kleberg County, Texas, and involves 1PointFive, a subsidiary of Occidental, and its partners, Canada’s Carbon Engineering and Australian engineering company Worley.

In a further development just after the DOE DAC Hubs announcement, 1PointFive announced the acquisition of Carbon Engineering for total cash consideration of approximately $1.1 billion.

All Nippon Airways (ANA), Japan’s largest airline, has already announced a CO2 credit purchase agreement with 1PointFive.

Carbon Engineering’s DAC technology is based on an air contactor – a large structure modelled on industrial cooling towers – and a giant fan that pulls air into this structure, where it passes across thin plastic surfaces that have potassium hydroxide solution flowing over them. This non-toxic solution chemically binds with the CO2 molecules, removing them from the air and trapping them in the liquid solution as a carbonate salt.

The CO2 contained in the carbonate solution is then put through a series of chemical processes to increase its concentration, purify and compress it, so it can be delivered in gas form ready for use or storage. This involves separating the salt out from solution into small pellets in a structure called a pellet reactor, which was adapted from water treatment technology. In this chemical reaction, in addition to precipitating out the calcium carbonate pellets, the original capture chemical to be used in the air contactor is regenerated.

Fig Leaf

DAC is not, however, without its critics and Jonathan Foley, executive director of San Francisco-based Project Drawdown, a group that publicizes climate solutions, suggested to The Guardian newspaper that the money being invested in it could be much better spent on actual climate solutions that would be cutting emissions from the start, citing energy efficiency and lowering emissions from agriculture, transportation and electricity generation as better approaches.

“What worries me and a lot of other climate scientists is that it potentially creates a fig leaf for the fossil fuel industry – the idea that we can keep burning stuff and remove it later,” he said. There is also the question of cost. In a 2022 report for the Washington-based World Resources Institute, authors Katie Lebling, Haley Leslie-Bole, Zach Byrum and Liz Bridgwater observe that despite its benefits and flexibility, DAC is more costly per ton of CO2 removed compared to many mitigation approaches and natural climate solutions.

“The range of costs for DAC vary between $250 and $600 per ton of CO2 today, depending on the technology choice, low-carbon energy source and the scale of their deployment – for comparison, most reforestation costs less than $50 per ton,” the authors state.

However, with the rate of deployment now poised to rapidly accelerate, prices will fall significantly, and even prior to the recent announcements, Heirloom said its carbon removal credits would cost less than $100 per ton of CO2 from the smaller-scale California plant by 2035.

Permanence

It’s also important to note that DAC offers quantifiable and permanent storage, whereas natural carbon removal solutions like trees are at risk of deforestation and climate change-induced threats such as wildfires and drought.

DAC also provides atmospheric clean-up, which is a public good rather than a product people need to purchase, so opportunities for direct revenue are more limited. Captured CO2 can be sold for use in products from concrete aggregate to carbon fibre production, but these markets don’t typically provide enough revenue to offset the cost of capture. The largest market for CO2 today is enhanced oil recovery (EOR), which is controversial given its connection to fossil fuel production.

“Ultimately, the greatest climate benefit for DAC comes from geologic sequestration for which there is no revenue opportunity beyond public policy support,” the 2022 World Resources Institute report concludes. “Public investment in and support of carbon removal technology has increased in the past few years, but more will be needed to scale sufficiently and avoid the worst impacts of climate change.”

In the USA, it appears that is exactly what’s happening right now.