As Demands for Environmental Accountability Increase, Companies Turn to New Tools to Tell Their Sustainability Story

These days, the topic of environmental, social and governance (ESG) strategies taking precedence throughout companies of all sizes within the filtration industry, as well as a myriad of other industries across the globe.

Whatever you call it – ESG, sustainability, or corporate responsibility – there is a growing recognition that companies need to focus not only on tending to their bottom lines, but also on their impact on communities, the environment, and society as a whole. Indeed, there has been a macro societal shift in expecting how businesses should behave – an expectation of a more defined environmental contract.

Historically speaking, it’s important to understand that ESG is nothing new – it grew out of the sustainability movement of the ’90s and early 2000s, which started to put pressure on the corporate world to consider the environmental impacts of their actions. Today, having a solid ESG record is a sign of a well-run, forward-looking business. And it’s what stakeholders – customers, suppliers, employees, and investors – expect from businesses within the filtration industry and beyond.

But ESG initiatives offer plenty of challenges. In a recently released e-book, Nefab, the developer of GreenCalc, a data-driven tool that tracks and quantifies all financial and environmental data in a company’s supply chain, pointed to several ESG challenges facing the traditional supply chain. Not only does transportation and packaging have a major impact on CO2 eq emissions and global warming in both local and global levels, but sustainable solutions are critical in this area, yet are frequently overlooked by companies of all sizes.

In addition, improper recycling of the majority of packaging can pose significant challenges, limiting the ability of moving to a more circular use of resources. For example, unoptimized packaging practices within supply chain activity can result inefficient use of cargo space, resulting in ships, trucks and aircraft shipping “air.”

International Filtration News connected with Nefab’s head of sustainability, Charles de Muizon, to learn more about ESG reporting and the challenges facing companies that want to focus on ESG initiatives, including emissions within the supply chain environment.

International Filtration News: What is the importance of ESG reporting and measuring a company’s carbon footprint?

de Muizon: We are in a state of climate change crisis and every responsible business must do its part to join the fight. One way to do this is by applying the three main principles of a circular economy – reduce, reuse, and recycle (3Rs) – to the design process of each packaging and logistic solution. Another is to implement tools and systems to evaluate environmental footprint and maximize resource efficiency. Environmental, social and governance (ESG) is a framework for defining your business’ overall sustainability management strategy, including specific initiatives and KPIs which progress can be monitored through data-driven tools.

IFN: What type of impact can supply chains have on a company’s ESG?

de Muizon: ESG has an instrumental impact on supply chains. In fact, it’s been proven that supply-chain ESG risk assessment helps an organization to identify the most critical risks of the supply chain and decide on the relevant mitigation actions and allocate resources accordingly. After all, we are all connected and are part of each other’s supply chains which are driven by our customers’ actions. That is why all suppliers will strive to align and support their customers to reach their sustainability targets because it affects their own supply chains as well.

With the climate clock ticking, both the industry and legislators are urged to come up with solutions to protect the limited natural resources. Building a network of trusted partners that would benefit from joining the circularity process will be key.

IFN: What are the current sustainability issues and challenges facing the fiber and filter media industry?

de Muizon: With the climate clock ticking, both the industry and legislators are urged to come up with solutions to protect the limited natural resources. The natural solution is to switch to reusable, recyclable, and biodegradable materials – which is where fiber and filter media come into play.

Although the recycling of paper fibers is well implemented in many countries, the collection of waste and implementation of circularity business models is still missing. Building a network of trusted partners that would benefit from joining the circularity process will be key.

IFN: How can companies evaluate the total lifecycle of products and the impact on a company’s ESG? How does Nefab’s GreenCalc Tool help in this regard?

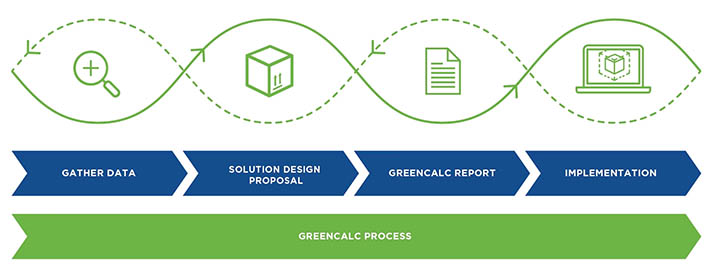

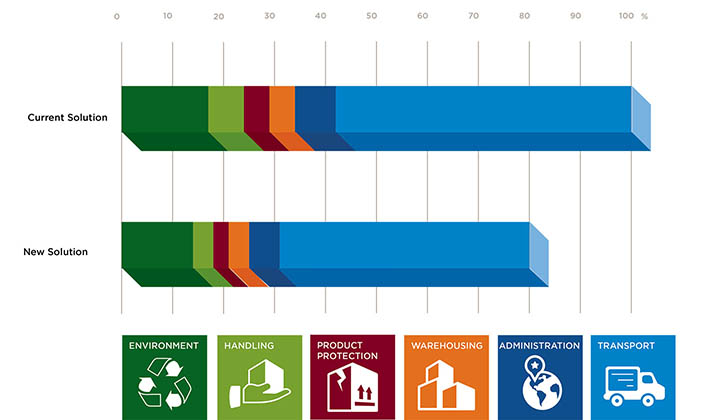

de Muizon: Collecting accurate data will be key. Companies will need data to report their progress on reducing their carbon footprint. Although, quantifying your own carbon footprint is not a difficult thing to do, what creates real value is the added value in the form of support in monitoring and analyzing the data in real time and identifying actionable ways of improvement (for example, by redesigning your packaging and flows to save CO2). This is exactly what GreenCalc™ does, Nefab’s proven digital tool for identifying CO2 eq emissions and cost savings in supply chains. By analyzing the total lifecycle of your packaging solutions from the cradle to the grave, GreenCalc™ supports the global demand for optimizing transport efficiency and driving sustainable supply chains.

By measuring the emissions, waste, returnability, and different types of materials in all flows through its dedicated Scope 3 GAIA dashboard, the tool allows a company to assess the packaging and logistics environmental impact baseline but also monitor the impact of the improvement initiatives. Since 2021, Nefab completed over 3,000 GreenCalc™ analyses, assisting its customers in reducing, on average, 31% tons of CO2 eq emissions over the entire life cycle of the packaging, including its production, transportation, and end-of-life.

IFN: What is the role that CO2 plays in the sustainability of supply chains?

de Muizon: I believe that we all should look at CO2 as a motivator, because it incentives businesses to reduce their carbon footprint. As a result, by focusing more on the importance of the sustainability initiatives, more improvements will be implemented for the benefit of all.

IFN: How can companies save resources and improve sustainability in their supply chains?

de Muizon: It all starts with the design. Following sustainable design guidelines that ensure that all packaging solutions are produced according to the 3Rs principle is a good start. Additionally, reducing the number of materials and resources needed to design and ship the packaging is one of many ways where a company can generate savings while minimizing its green footprint. An efficient way to reduce the use of resources is to switch to lighter materials to decrease the overall weight, more ergonomic design to eliminate the transportation of air or improve the logistics operation.

For example, by redesigning a packaging solution that enables the product to be stacked during transportation, Nefab’s customers were able to increase the load per truck, resulting in approximately 20% financial savings per year, in addition to CO2 eq savings. In fact, the latest version of GreenCalc™ can evaluate over 44 different packaging materials which allows to model almost any type of solution. Last, but not least, collecting data and quantifying the impact of the packaging, improve its design and track the progress of the supply chain flows.

So, is the ESG movement here to stay? Well, it appears that there is now a real desire not just to measure companies’ impacts, but also to manage them. And this is not going to let up anytime soon.