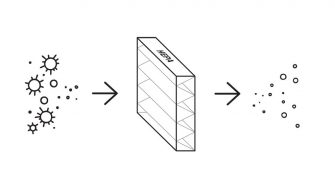

HVAC / HEPA / ULPA

High-efficiency filters and laminar air flow systems needed in the battle against COVID-19

At the time of this writing, 800,000 people around the world have died from COVID-19. There have been 22 million reported infections. There is growing evidence that small aerosols are …

Filtration terminology – the rest of the story

In our current global marketplace and supply chains, consumers and users require some level of fluency in the terms and standards that define the products they acquire and use. Our …

Perspectives & challenges in IAQ – takeaways from AHR Expo

I made the trip to Orlando in February for the 2020 AHR Expo. I traveled to this event with the objective of determining the level of interest in an INDA …

Simplify your HVAC investment with a total cost of ownership analysis

Deciding which HVAC filtration solution is the best choice requires a comprehensive understanding of your system needs and the costs associated with HVAC filtration. Simplifying the decision-making process is an …

Fundamentals for cleaner and healthier air

A World Bank study maintains that air pollution costs the world trillions of dollars a year and contributes to the premature death of millions of people a year around the …