The bonding of fibers and polymers in the filter media manufacturing process can be performed by mechanical, chemical or thermal processes. Chemical bonding in filtration is typically employed to provide added binding of raw materials and/or added functionality to the filter media (anti-microbial, hydrophobicity, hydrophilicity, etc.).

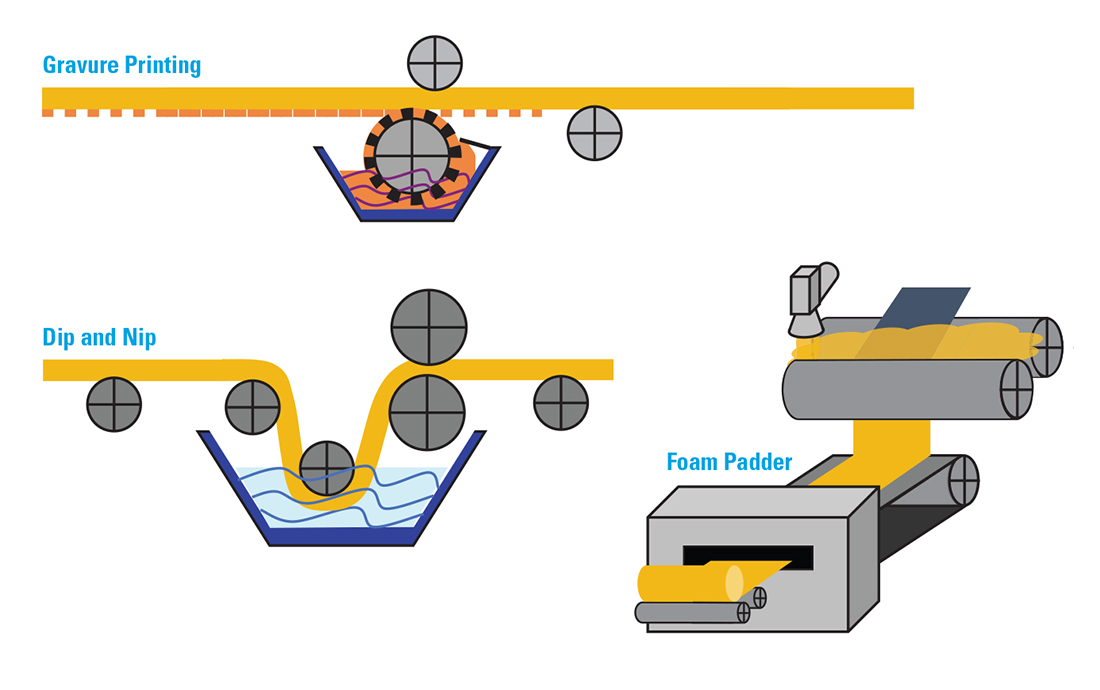

Gravure printing is a process whereby the filter material is rolled over a drum with surface recessions to provide the effect of regular and uniform depressions on the filter material. It can be used to apply chemical treatment to the filter surface in an evenly spaced and consistent fashion.

This technique can be employed where a fiber-reinforced composite is desirable for filtration, but it can be a challenge for airflow, as it increases the density of the web.

Dip and nip is a process that literally dips the filter material into a chemical solution before running it through a barrel press to squeeze excess solution out of the filter material. This technique can be employed where a fiber-reinforced composite is desirable for filtration, but it can be a challenge for airflow, as it increases the density of the web.

The foam padder method of applying a chemical treatment involves running the filter material through a series of rollers where a foam is applied with the necessary solution. The solution can also be applied in this fashion via a spray. This is method is a good fit where a light application of solutions is desirable.

The material provided for this Process Profile is courtesy of INDA’s Filter Media Training Course, inda.org/training/filter-media-training.php. INDA, Association of the Nonwoven Fabrics Industry, is the owner of International Filtration News.