A Technique That Improves Accuracy in Measuring the Most Penetrating Particle Size of High Efficiency Air Filter Media

Size-resolved particle penetration measurements are key to understanding the interaction of aerosol particles with an air filter. These measurements can reveal valuable insights about the relative influences of different mechanisms for particle capture and are used to determine the most penetrating particle size (MPPS) of filter media. In uncharged media, deposition of particles smaller than the MPPS is mostly influenced by diffusion, whereas capture of larger particles is mostly influenced by interception and impaction (electrostatically charged filters may also capture uncharged particles by induced charge forces and charged particles by Coulombic forces).

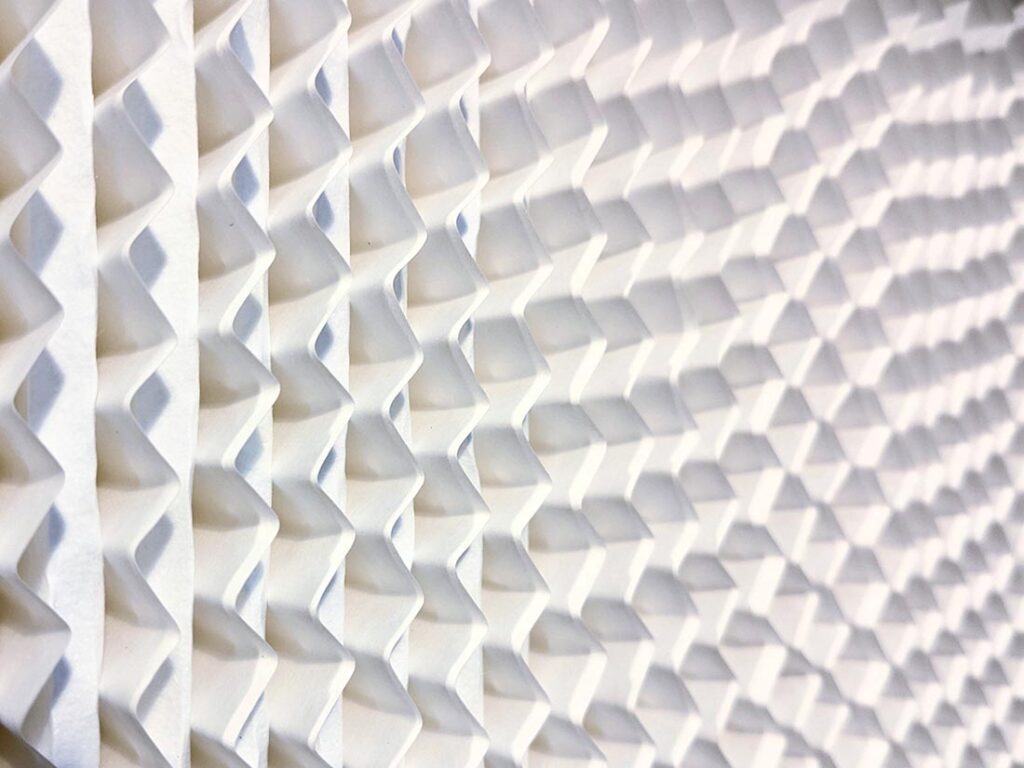

Filter media are designed to promote a high level of interaction between airborne particles and individual fibers or pores – the aim is to maximize the capture of pollutants, contaminants and pathogens for applications such as heating, ventilation and air-conditioning (HVAC) systems and personal protection equipment (PPE).

Polydisperse aerosols and scanning instruments can be used to determine filtration efficiency by particle size, but greater precision and repeatability are usually achievable using monodisperse aerosols and particle counters. “Monodisperse” means particles are ideally of the exact same size, but in reality they are narrowly distributed around the size setpoint (usually with a geometric standard deviation of less than 1.2). Monodisperse aerosols can be directly generated (e.g., using a condensation method), or particle classifiers can be used to obtain a particle size cut: a polydisperse aerosol is generated (e.g., using a nebulizer), which is classified to obtain a monodisperse aerosol. The classifier method offers greater flexibility for selecting particle sizes from a range of aerosol sources, as well as faster adjustment of the size setpoint during testing.

If aerosol particles were all spherical and of the same material density, it would be straight forward to define the size of the particle by its physical diameter. In reality, the composition and morphology of particles can vary widely, depending on how the aerosol is generated and any subsequent chemical or physical processes that may occur. Particle size is therefore defined by an equivalent metric, which is determined in this case by the operating principle of the particle classifier.

A potentially significant source of error is the transmission of larger, multiply charged particles with the same electrical mobility as singly charged particles at the selected size. Therefore particles in the DMA output are mono-mobility, but not always monodisperse, and this may affect filter penetration measurements.

Classifier Techniques

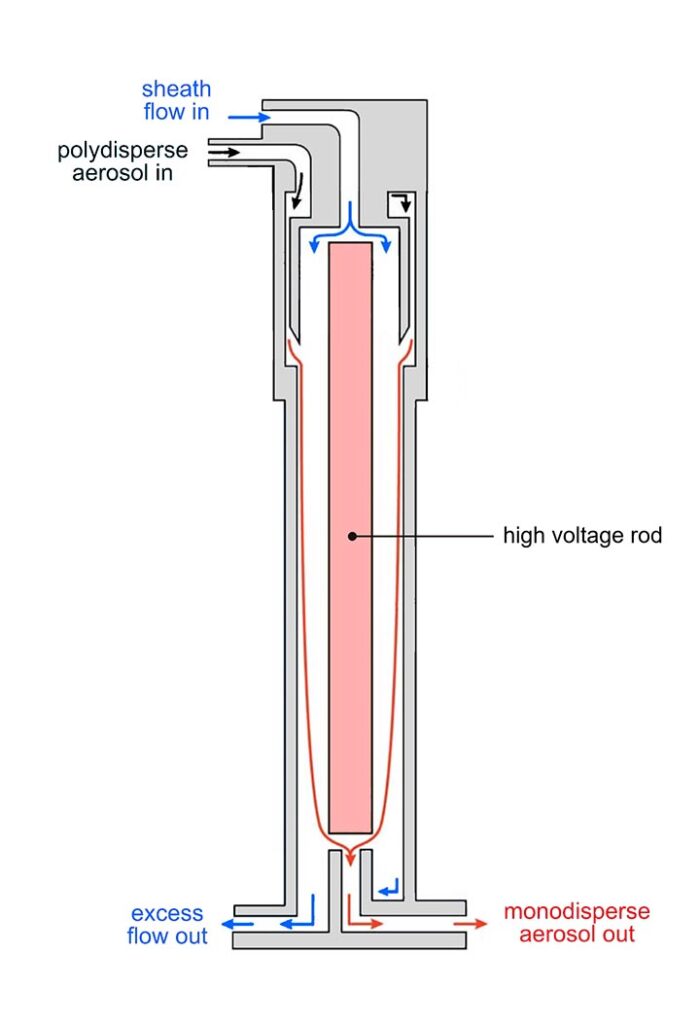

Electrical mobility instruments such as the Differential Mobility Analyzer (DMA) have been used for many years by aerosol scientists to classify particle size. The DMA was developed by E. O. Knutson and K. T. Whitby at the University of Minnesota in the 1970s and classifies particles based on their electrical mobility equivalent diameter. The mobility diameter is important for analyzing particle transport by diffusion and electrostatics. In the DMA, an electric field is applied across a column to induce a known electrostatic force, so that charged particles drift across a parallel sheath flow and experience opposing drag (Figure 1). It is the ratio of these opposing electrostatic and drag forces that determines the mobility of the particles selected.

The aerosol must be charge-conditioned before entering the DMA column using a radioactive or X-ray neutralizer device (the term “neutralizer” can be misleading: the particles are brought to an equilibrium charge distribution rather than rendered completely neutral). The DMA is designed to transmit singly charged particles of either positive or negative polarity; this means the transmission efficiency is limited by the charging efficiencies in the neutralizer (as particles get smaller, a higher proportion are

uncharged).

A potentially significant source of error is the transmission of larger, multiply charged particles with the same electrical mobility as singly charged particles at the selected size. Therefore particles in the DMA output are mono-mobility, but not always monodisperse, and this may affect filter penetration measurements.

Since 2016, classification by a particle’s aerodynamic equivalent diameter is possible using the Aerodynamic Aerosol Classifier (AAC). The aerodynamic diameter is defined as the diameter of a spherical particle with a density of 1000 kg m–3 that has the same terminal settling velocity as the particle of interest. It is the most relevant metric for particle size when interception and inertia are important, such as respiratory deposition, atmospheric lifetime and settling, and particle collection by filters, cyclones and impactors.

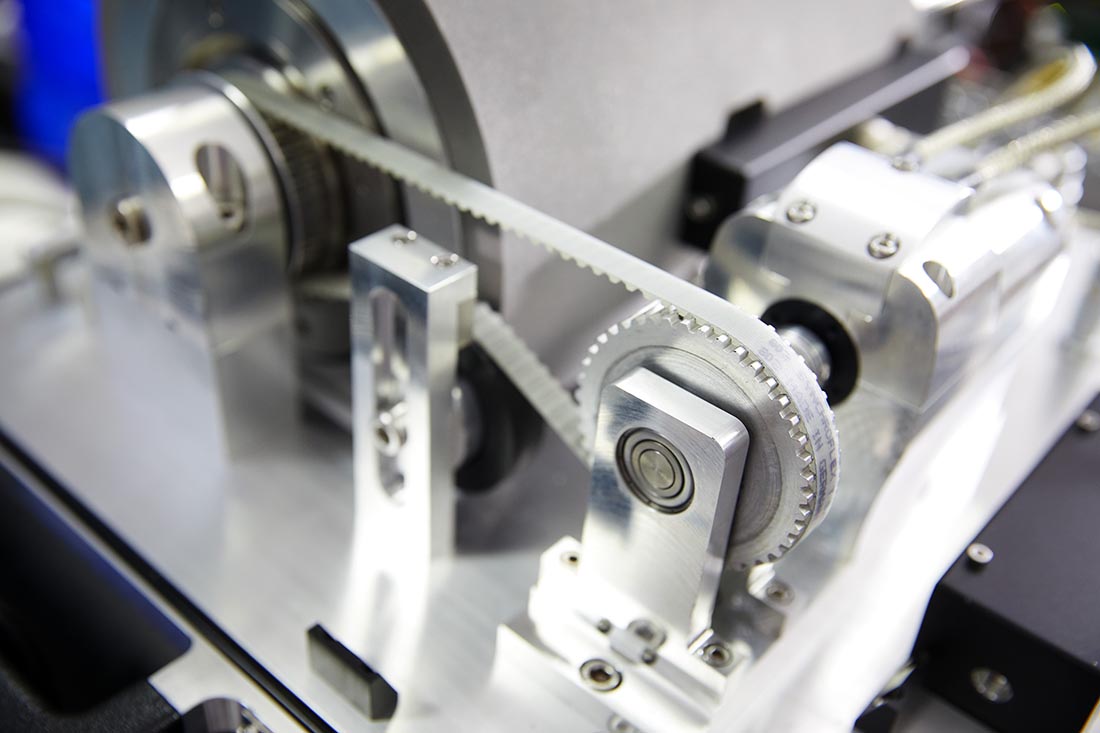

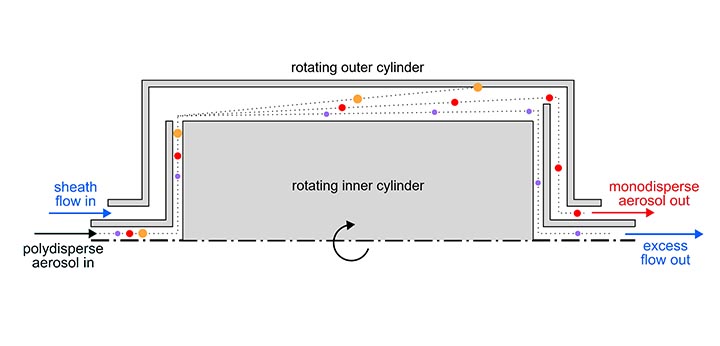

Developed by F. Tavakoli and J. S. Olfert at the University of Alberta, the AAC uses rotating concentric cylinders with a sheath flow to induce known centrifugal and drag forces on each particle sampled (Figure 2). It can be thought of as translating the DMA into a rotating frame; there is axial sheath flow, but the radial force is centrifugal rather than electrical. This means there is no dependence on the aerosol charge state and no requirement to use an upstream neutralizer device. Particles smaller than the selected aerodynamic diameter setpoint remain entrained in the sheath flow, while larger particles impact on the inner wall of the outer cylinder. The advantages of the technique are that it produces a truly monodisperse aerosol and its transmission efficiency is higher than the DMA since it is limited only by particle losses and not also by particle charge fractions.

The maximum rotational speed of the AAC cylinders is 7,000 rpm, which sets the minimum aerodynamic diameter that can be classified to approximately 25 nm (the exact figure depends on the sheath flow and the resolution of the size cut). Smaller mobility equivalent diameters are possible with the AAC, if using particles with high material density. Depending on the configuration of the column and flows, the DMA can classify mobility diameters below 10 nm (1 nm is possible with short column designs), but due to the maximum voltage before electrostatic breakdown, the upper limit is typically <1 micrometer. The upper limit of the AAC (determined by the minimum stable rotational speed) is >5 micrometers, which can be useful for fully characterizing the filtration performance of lower efficiency HVAC and PPE filter media, and for calibration of Optical Particle Counters (OPCs).

Determining the MPPS

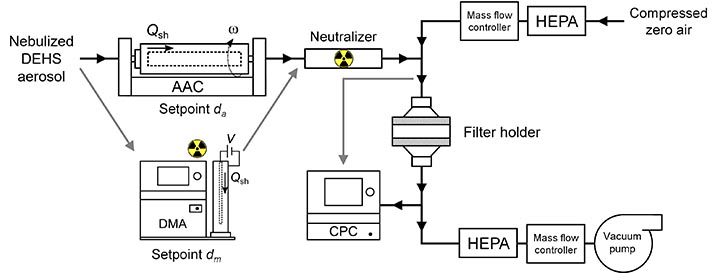

ISO 29463 was established in 2011 as an international standard for high efficiency air filters. It was derived from EN 1822, which defined the MPPS as an essential criterion for certifying the H and U filter grades. Operation of the DMA to classify particles from a nebulizer is covered in ISO 29463 part 2, along with a Condensation Particle Counter (CPC) to measure particle number either side of the filter sample under test. Use of a CPC ensures detection of the smallest particle sizes in the expected range for the MPPS (according to ISO 29463, this can be 120–250 nm for uncharged glass fiber media in the H and U grades, and below 100 nm for PTFE membranes), which are generally below the minimum detectable size of OPCs.

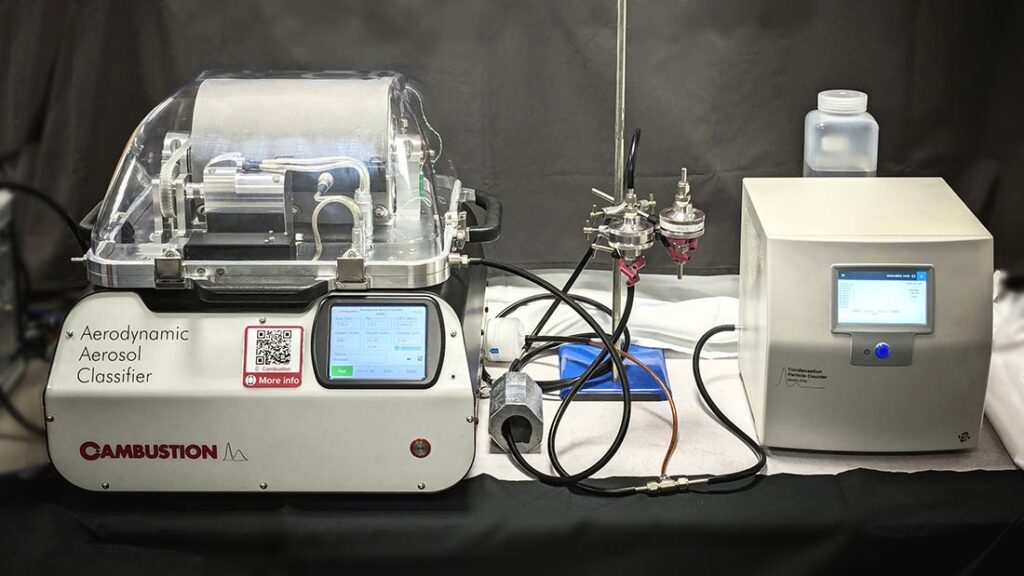

In experiments reported at the AFS Filtcon conference in Houston this year, an AAC and a DMA were used alternately to measure classified particle penetration through samples of high efficiency air filters (Figure 3). Measurement of size resolved particle penetration through flat sheet media is covered in ISO 29463 part 3, which stipulates for a minimum of six approximately logarithmically equidistant particle sizes to construct a minimum efficiency curve. The nebulized test aerosol was undiluted Di-Ethyl-Hexyl-Sebacate (DEHS), which consists of spherical particles with a material density just under 1000 kg m–3. This means the aerodynamic and mobility equivalent diameters lie close to each other, and it is straight-forward to convert between the two size metrics to calculate the equivalent setpoints on each classifier.

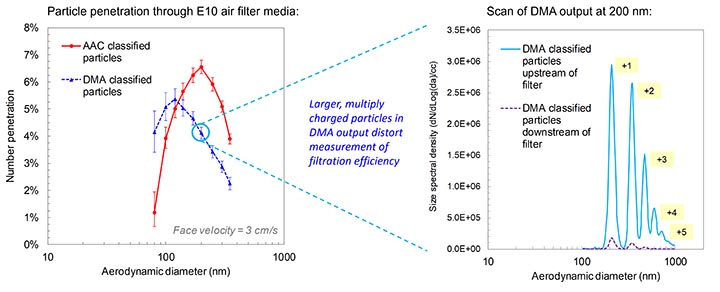

While E10 does not have an equivalent grade in ISO 29463 that requires measurement of the MPPS, the lower efficiency than the H and U grades mean artifacts in the filtration data are more clearly revealed.

Multiple charge artifacts in the DMA output can have a significant effect on the calculated particle penetration at particular mobility diameters, depending on the position of the size cut relative to both the peak of the input distribution from the nebulizer and the MPPS of the filter medium. The error tends to be greatest when particles are classified from the left shoulder of the input distribution, drawing multiply charged particles over the peak, and where this mobility setpoint lies at or just below the MPPS (which depends on the flow rate through the filter and the filter medium properties). Conspicuous differences emerged between the two classifiers in tests on an EN 1822 E10 filter medium (Figure 4). While E10 does not have an equivalent grade in ISO 29463 that requires measurement of the MPPS, the lower efficiency than the H and U grades mean artifacts in the filtration data are more clearly revealed.

Agreement in results between the AAC and DMA was only obtained towards the upper limit of the tested particle size range with an impactor installed upstream of the DMA column to minimize transmission of larger, multiply charged particles. However, this measure becomes impractical for mobility diameter setpoints below a few hundred nm, since higher flows through the impactor and/or narrower nozzles are required that can cause a significant pressure drop downstream (which can affect the counting accuracy of the CPC, and lead to difficulty ensuring a consistent flow rate through the filter medium).

The recommendation in ISO 29463 part 2 is to adapt the size distribution from the nebulizer to suit the selected mobility diameter. In this case, dilution of DEHS in a volatile solvent, such as iso-propanol, would reduce the size of the input distribution due to evaporation of the solvent. The aim is to classify particles with the DMA sufficiently far down the right side of the distribution so that larger, multiply charged particles are in the tail and therefore diminished in number. In practice, this means an array of nebulizers may be necessary with a range of concentrations of the aerosol substance in the solvent to cover the particle size range of interest. If classifying by aerodynamic diameter instead, this concern is eliminated and a single nebulizer should be sufficient.

Particle Charge Distribution

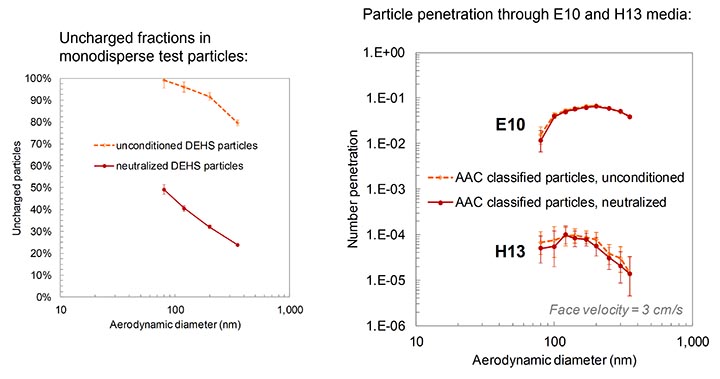

Since the DMA output comprises charged particles only, a neutralizer is required downstream so that an equilibrium charge distribution is prescribed on the aerosol incident on the filter medium. This necessitates a second neutralizer in the setup, in addition to the neutralizer installed ahead of the DMA column. Since there is no need for a neutralizer ahead of the AAC, further tests were performed with the AAC only, with and without the downstream neutralizer (i.e., ahead of the filter medium), and the charge state of the nebulized DEHS test aerosol was characterized. These measurements show that nebulization of undiluted DEHS generates relatively few charges, and close agreement in filtration data is obtained between unconditioned and neutralized particles (Figure 5). Therefore the neutralizer could justifiably be omitted altogether for uncharged filter media, if the test aerosol is nebulized using undiluted DEHS and classified by aerodynamic diameter. Since radioactive neutralizers have stringent licensing requirements, this can be of great benefit considering resources available at testing locations, and health and safety regulations.

Moreover, the significantly higher transmission efficiency of the AAC (unlike the DMA, particle transmission is not limited by charge fractions) means a higher concentration of truly monodisperse test particles is available. This can be important for testing full-scale HVAC filter elements, but also for production line testing of U grade filter media (as described in ISO 29463 part 3 Annex B), when the media may be challenged only with monodisperse particles classified close to the MPPS.

References:

- Johnson, T. J., Irwin, M., Symonds, J. P. R., Olfert, J. S., Boies, A. M. (2018). Measuring Aerosol Size Distributions with the Aerodynamic Aerosol Classifier. Aerosol Sci. Technol. 52, 655–665. https://doi.org/10.1080/02786826.2018.1440063

- Knutson, E. O., Whitby, K. T. (1975). Aerosol Classification by Electric Mobility: Apparatus, Theory, and Applications. J. Aerosol Sci. 6, 443–451. https://doi.org/10.1016/0021-8502(75)90060-9

- Payne, S. D., Johnson, T. J., and Symonds,

J. P. R. (2023). Characterisation of the Aerodynamic Aerosol Classifier Transfer Function for Particle Sizes up to 5 Micrometres. Aerosol Air Qual. Res. 23, 230008.

https://doi.org/10.4209/aaqr.230008 - Payne, S. D., and Symonds, J. P. R. (2024). Classifying Aerosol Particles by Aerodynamic Diameter to Improve Accuracy of Size-Resolved Filtration Measurements. AFS Filtcon, 8-10 Apr 2024, Houston, USA. https://www.researchgate.net/publication/382801727_Classifying_Aerosol_Particles_by_Aerodynamic_Diameter_to_Improve_Accuracy_of_Size-Resolved_Filtration_Measurements

- Tavakoli, F., and Olfert, J.S. (2013). An Instrument for the Classification of Aerosols by Particle Relaxation Time: Theoretical Models of the Aerodynamic Aerosol Classifier. Aerosol Sci. Technol.47, 916–926. https://doi.org/10.1080/02786826.2013.802761