Refining Hydrogen Refueling Filtration

As the automotive industry pivots towards sustainable energy solutions, hydrogen fuel cell vehicles (FCEVs) have emerged as a promising alternative to traditional fossil fuel-powered vehicles. Hydrogen is abundant, produces zero tailpipe emissions, and can be generated using various renewable energy sources. However, the effective use of hydrogen as a fuel requires filtration to ensure its cleanliness and performance. This article discusses the importance and benefits of filtering hydrogen and considerations when designing a filter.

Hydrogen fuel cells convert chemical energy from hydrogen into electricity which powers the vehicle. The process involves a reaction between hydrogen and oxygen, producing electricity, water, and heat. The simplicity of this reaction, combined with the environmental benefits of using hydrogen, makes fuel cells

an attractive option for reducing greenhouse gas emissions and dependence on fossil fuels.

The Need for Hydrogen Filtration

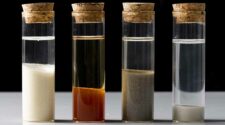

Despite its advantages, hydrogen fuel systems face several challenges, one of which is the need for clean hydrogen, free from contaminants and moisture. Contamination can originate from various sources, including production processes, compression, storage, and transportation and can have a detrimental effect on fuel cell performance, efficiency, and longevity, if not removed. Contaminants can accelerate wear and degradation of fuel cell components. Moisture in the hydrogen fuel source can hinder the electrochemical reaction, reducing the fuel cell’s efficiency and power output by preventing proper access of the hydrogen to the catalyst. Filtering hydrogen at the refueling pump can extend the lifespan of vehicles, reduce maintenance costs and enhance reliability.

Design Considerations

There are many potential dangers associated with hydrogen refueling due to its extremely high pressure, pressure cycling, hydrogen embrittlement and leakage potential. As a result, when designing a filter, consideration must be given to mitigate each potential hazard.

High Pressure – Many FCEVs use 700 bar nominal (10,000 psig) hydrogen refueling stations. ASME section VIII division 3 provides design rules for safe construction of high-pressure vessels. O-ring seals should use a backup ring to prevent them from extruding under the extreme pressure. Burst testing product samples is also recommended to confirm the design safety factor.

Pressure Cycling – In service, the filter will experience pressure swings from near 0 to full pressure and back again with every refuel. This presents fatigue issues with the metal housing. Sharp corners should be eliminated from the housing design to minimize stress risers and increase fatigue life.

Rapid depressurization can cause explosive decompression damage to o-ring seals. It’s important to use o-rings specially designed for rapid gas decompression service.

Hydrogen Embrittlement – Proper material selection is important for hydrogen service. Hydrogen causes metals to become brittle and susceptible to fracture. Hydrogen embrittlement occurs when hydrogen atoms are absorbed into the metal resulting in a loss of ductility. All structural metals are susceptible to hydrogen embrittlement, however it can be mitigated with proper material selection. ANSI/CSA CHMC 1-2014 and ASME B31.12 provide guidelines to aid in material selection. As a general rule, austenitic stainless steels with greater than 7% nickel are a good choice.

Leakage – H2 is a small molecule which means it is hard to contain and apt to leak. While leakage can probably never be eliminated, it can be minimized by using more than one seal.

Hydrogen Refueling Standards

As the hydrogen economy develops, regulatory standards are being established to ensure the quality and safety of hydrogen fuel. Compliance with these standards is essential for component manufacturers, systems integrators and refueling stations to maintain market access and consumer trust.

ISO 19880-1 – Gaseous Hydrogen –

Fueling Stations is an international standard that specifies requirements for hydrogen fueling stations. It addresses various aspects of hydrogen fueling, including safety, compatibility, performance and hydrogen quality.

CSA/ANSI HGV 4.1 – Hydrogen Dispensing Systems outlines safety requirements for the design, construction, and performance of hydrogen vehicle refueling systems. It addresses aspects such as equipment specifications, operational procedures, and safety protocols.

SAE J2601 – Fueling Protocols for Gaseous Hydrogen Vehicles specifies fueling protocols for hydrogen vehicles. It focuses on the refueling process, ensuring that it is safe, efficient, and consistent across diff-

erent fueling stations. It addresses refueling pressure, temperature considerations, refuel rates and hydrogen quality.

SAE J2719 – Hydrogen Fuel Quality for Fuel Cell Vehicles details hydrogen fuel quality specifications.

Furthermore, ISO 19880-1, CSA/ANSI HGV 4.1 and SAE J2719 state that the dispenser should have a filter that protects the vehicle from 99% of the particulates larger than 5 micron.

The Future of Hydrogen Vehicles

As the world seeks to cut greenhouse gas emissions and move toward a more sustainable future, do hydrogen powered vehicles have a bright future? Could they replace battery electric vehicles? FCEVs have advantages and face challenges.

Advantages

Faster Refueling – Hydrogen vehicles can be refueled in about 3 to 5 minutes, like conventional gasoline vehicles. This is significantly faster than the charging times for most electric vehicles, which can take anywhere from 30 minutes at a fast charger to several hours at a standard home charger.

Longer Range – Hydrogen vehicles typically offer a longer driving range compared to many battery electric vehicles. This makes them particularly appealing for long-distance travel and for applications such as commercial trucking, where range and refueling time are critical.

Weight Considerations – Hydrogen fuel cells can provide a higher energy density compared to batteries, making them more suitable for heavier vehicles, such as buses and trucks, where battery weight can be a significant drawback.

Battery Production and Recycling –The production of lithium-ion batteries raises concerns about resource extraction, environmental impact, and recycling challenges that are not a concern for FCEVs.

Challenges

Infrastructure Development – One of the most significant barriers to the widespread adoption of hydrogen vehicles is the lack of refueling infrastructure. Hydrogen stations are scarce, especially compared to the extensive network of electric vehicle charging stations. Building a comprehensive hydrogen refueling network requires substantial investment and coordination. There is also a general lack of awareness and understanding of hydrogen technology among consumers.

Production and Distribution – While hydrogen can be produced from various sources, the most common method today is steam methane reforming, which emits carbon dioxide. Transitioning to greener hydrogen production methods, like electrolysis, is currently more expensive and energy intensive.

Cost of Fuel Cells – Hydrogen fuel cell technology is still relatively expensive compared to battery technology. The cost of fuel cell systems and hydrogen storage solutions needs to decrease to make hydrogen vehicles more economically viable for consumers.

Energy Efficiency – The efficiency of converting renewable energy into hydrogen and then using that hydrogen in fuel cells is lower than the direct use of electricity in battery electric vehicles. This can make hydrogen less appealing from an energy utilization standpoint.

Potential for Growth

Hydrogen-fueled vehicles have the potential to complement rather than completely replace electric vehicles in the transportation sector. Each technology offers unique advantages and faces specific challenges. Hydrogen vehicles may be particularly well-suited for applications requiring rapid refueling and long ranges, such as commercial trucking and public transportation. In contrast, battery electric vehicles are currently more accessible to consumers due to established infrastructure and lower operating costs.

Ultimately, the future of sustainable transportation may not be a matter of one technology replacing the other but rather a combination of both hydrogen and electric vehicles, each serving different market needs and applications.

As the demand for hydrogen fuel cell vehicles continues to grow, the importance of effective filtration is crucial. Ensuring the cleanliness of hydrogen is critical for optimizing fuel cell performance and longevity. Moreover, compliance with established standards is essential for maintaining quality and safety in the hydrogen refueling process.

By investing in filtration and adhering to rigorous standards, stakeholders can ensure that hydrogen remains a viable and sustainable alternative to traditional fuels. As we move towards a cleaner, greener future, hydrogen filtration will be pivotal in unlocking the full potential of hydrogen as a power source for vehicles and beyond.