Carbon capture, utilization and storage (CCUS) is regarded as a key part of the global strategy for reaching net zero by 2050 and is set to play a vital role in mitigating the adverse effects of climate change. Legislative mandates on reducing emissions and incentives for carbon removal are increasing across the world.

With a surge in the use of CCUS, it is more important than ever to be aware of the challenges involved with capturing, processing and storing carbon. Harmful impurities including sulfur dioxide, nitrogen oxide, oxygen and water in the carbon dioxide stream cause operational issues, reduced carbon capture efficiency, critical equipment damage, unscheduled downtime and increased maintenance costs. If the carbon dioxide is not purified to the right level when being transported – either for storage in geological reservoirs or for making new products – there is also a threat of corroding pipelines and unwanted side reactions. Proactive contaminant removal can therefore provide a good return on investment.

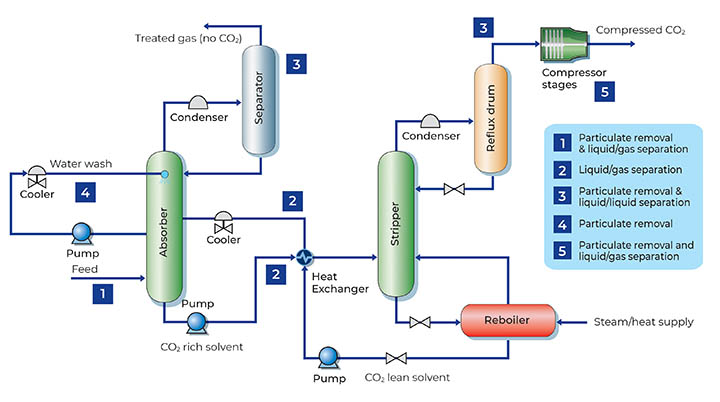

As decarbonization projects continue to accelerate, filtration and separation technology will play a critical role across the value chain of CCUS. This particularly applies to absorptive (solvent-based) carbon capture, which is currently the most commonly used CCUS method. This is primarily because it is more economical and at a more mature stage of development than other existing methods such as cryogenics and chemical looping.

The compression and storage of carbon dioxide is a key part of the CCUS process, with CO2 needing to be compressed to reduce its volume for efficient transportation and processing. As compressors

are highly sensitive to contaminants, which can quickly cause corrosion and lower compressor yields, it is vital to support them with the right technology.

High tech coalescers, for example, can be used to boost compressor operation and reliability by removing carry-over liquids (oil that seeps past the separator filter into the discharge piping), free water (condensation) and particulate matter (a mixture of solid and liquid droplets). When compressed carbon dioxide is sent though long pipelines to underground reservoirs for storage, it can also contain solid contaminants which can foul the reservoir. Installing high efficiency particulate filters at the reservoir inlet is necessary to solve this issue.

It is clear that carbon capture is vital to a wider energy transition vision and meeting global net zero emissions. While carbon capture technology has been around for decades, there needs to be a massive ramp up in CCUS projects to meet climate targets by 2050. More investment in CCUS technology is required, with filtration and separation applications playing a key role in maintaining high carbon capture efficiency and reliable equipment operation, as well as meeting safety regulations.

Collaboration between tech suppliers, industry and governments is going to be pivotal in providing a sustainable and economic solution to meet these needs.