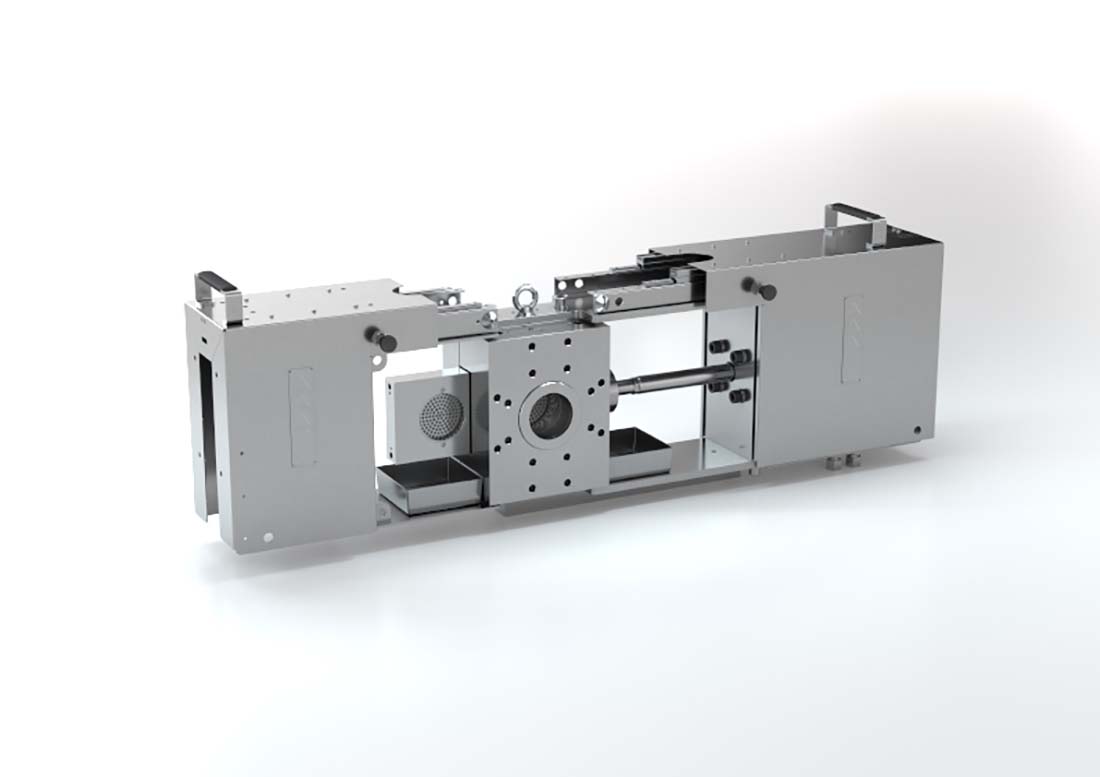

MAAG Group announced the launch of an updated melt filtration product portfolio that supports compounding processes. The flat-side technology, FSC, covers a wide range of viscosities and temperatures for low-viscosity polymers, such as hot-melt adhesives. MAAG’s design allows for leakproof operation, and the metal hybrid sealing system provides process reliability, handling temperatures up to 320 C.

The piston screen changers, DSC and CSC, are available with three different cavities. The standard round cavity for high-filler content, the enlarged “PE” cavity for versatility in balancing throughput and filler loading and the “R” cavity in the form of a curved sieve that delivers a larger filter area.