In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: April 10, 2025

Mott Corp. Supports US Dairy Farm With Wastewater Filtration Systems

Mott Corporation headquartered in Connecticut announced a $40 million agreement with a large U.S. dairy farm operation to deploy its custom filtration solutions. This strategic partnership will involve deploying advanced filtration systems to treat over two million gallons of wastewater each day.

The custom-designed system was specifically tailored to address the unique requirements of the dairy industry, providing an efficient and cost-effective solution for wastewater treatment. This collaboration highlights Mott’s ongoing commitment to delivering innovative solutions that improve operational efficiency and promote sustainability for its clients.

The installation of Mott’s proprietary Microfiltration (MF) and Sub-Induction Time Reverse Osmosis (SIT-RO) systems simplifies processes and enhances efficiency. Additionally, this approach reduces the need for common chemicals and other additives, leading to lower operating costs.

SUEZ and Partners Commence Construction of Philippines’ Largest Seawater Desalination Plant

SUEZ, a global leader in environmental services, and JEMCO, a premier construction company in the Philippines, together with Metro Pacific Water, a key water and wastewater infrastructure investor fully-owned by Metro Pacific Investments Corp. (MPIC), commenced the construction of a seawater reverse osmosis (SWRO) desalination facility in Metro Iloilo— the largest of its kind in the Philippines. Slated to be completed in 24 months, this project will help address the critical shortage of drinking water in the region, supplying sustainable and reliable potable water to local communities.

The existing fresh water sources in Metro Iloilo have become severely strained and are no longer capable of meeting the increasing demand of the region. This situation has been exacerbated by seasonal fluctuations in rainfall, disrupting the replenishment of these finite water supplies, revealing the urgent need to identify and develop alternative sources of water to ensure the long-term sustainability of the region.

To tackle the region’s shortage of potable water, Metro Pacific Water awarded to SUEZ and JEMCO a project to design, build and operate a seawater reverse osmosis desalination facility. The SWRO desalination plant will have an estimated production capacity of 66,500 cubic meters per day, with over 97% of which to be supplied to the residents as drinking water, benefiting approximately 50,000 households. The remaining part will be used for the production of demineralized water to support the operation of the adjacent power plant.

Separator Spares & Equipment Signs Distributor Agreement with Facet Filtration and Kaydon Filtration

Separator Spares & Equipment, LLC announced it has signed a distributor agreement with Facet Filtration and Kaydon Filtration, two well-established names in the oil filtration industry. This strategic partnership strengthens the company’s ability to deliver high-quality oil filtration solutions to customers across the maritime, oil & gas, power generation, and industrial sectors. Under the new agreement, Separator Spares & Equipment, LLC is now an Authorized Distributor for Facet and Kaydon Filtration products, including coalescers, separators, fuel and lube oil filtration systems, and portable filtration units.

Facet Filtration and Kaydon Filtration, both part of the Filtration Group, are known for decades of engineering excellence and industry leadership. Their filtration technologies are crucial to maintaining equipment reliability, minimizing downtime, and safeguarding systems against contamination.

With this agreement, Separator Spares & Equipment, LLC continues to build on its mission to provide quality-driven solutions for separation, heat transfer, and oil filtration needs – offering a broad range of spares, equipment, and technical support to meet the evolving demands of today’s industries.

Metso is Awarded With a Thickener Modernization Order in Mexico

Metso has entered into an agreement to provide a comprehensive thickener modernization for a customer site in Mexico. The objective of the modernization is to improve water recovery rates and decrease the amount of process water required, which is particularly important for areas experiencing water scarcity. Furthermore, the retrofits will enhance equipment performance, thereby reducing operating costs and increasing operational efficiency.

The total value of the order is around EUR 15 million and it is the largest services order Metso has received for a thickener modernization. Approximately EUR 11 million is recorded in the Minerals segment’s first-quarter orders received for 2025; the remaining amount will be accounted for in the two subsequent quarters.

The scope of supply includes retrofitting another supplier’s two thickeners by replacing the existing thickeners with Metso High Rate Thickeners. A key component of this modernization effort is the integration of Metso’s Reactorwell™ feed system, which is part of the Metso Plus portfolio. The innovative sustainable technology is designed to enhance thickener performance while reducing flocculant consumption. Metso will also provide flocculant dosing units as part of a comprehensive package, facilitating accurate chemical dosing, ensuring optimal thickener performance and smooth operational integration.

Camfil Strengthens Global Footprint with New Presence in Nepal

Camfil has broadened its global operations by establishing a presence in Nepal, marking a significant milestone in its mission to deliver clean air solutions worldwide. This expansion reinforces Camfil’s commitment to supporting healthier and more sustainable environments globally.

Rahul Kapoor, Managing Director of Camfil India, shared his thoughts on the development: “Nepal offers exciting potential across a number of sectors, including healthcare, pharmaceuticals, manufacturing, data centres, and hospitality. With growing awareness around air quality and its impact on both health and productivity, Camfil’s solutions will play an important role in helping organisations achieve high standards of indoor air quality. This initiative supports our belief that clean air should be a basic human right.”

As part of the market entry phase, Camfil’s team connected with key stakeholders in Nepal, highlighting the importance of clean air and introducing its cutting-edge air filtration technologies. In Nepal, Camfil’s offering will include Comfort Air Filtration, Clean Process Solutions, Indoor Air Quality Management, Molecular Contamination Control, and Air Pollution Control.

To ensure strong local support and service delivery, Camfil has partnered with an authorized distributor in Nepal to supply its world-class air filtration products and services. Reflecting on the company’s strategic focus in the region, Jayant Kaushal, Deputy President (APAC), said: “Camfil’s expansion into Nepal is a clear sign of our commitment to advancing air quality solutions across South Asia. As India moves forward with the adoption of IS 17570:2021/ISO 16890:2016 standards, this growth enables us to support industries and communities throughout the region even more effectively.”

CLEANR to Help Campuses Fight Microplastic Pollution

CLEANR has launched a new offering that will enable U.S. universities to significantly reduce their microplastic emissions. Under the program, CLEANR will deploy its breakthrough microplastics filter to on-campus washing machines to prevent microplastics from going down the drain and entering the environment.

CLEANR first debuted its filters at Case Western Reserve University (CWRU) as part of the institution’s sustainability efforts.

By focusing on washing machines, universities can help stop up to a third of microplastics from entering our waterways.

“By focusing on washing machines, U.S. universities can join in stopping up to a third of microplastics from entering our waterways,” said Max Pennington, Co-Founder & CEO of CLEANR. “Our filtering technology makes the job almost as simple and easy as removing lint from a dryer for university communities and makes a measurable impact on microplastic emissions.”

Washing machine wastewater is the world’s largest source of microplastic pollution, according to the International Union for Conservation of Nature. CLEANR’s filter—based on its core VORTX technology—was recently certified by the prestigious Shaw Institute to remove over 90% of microplastics as small as 50-microns.

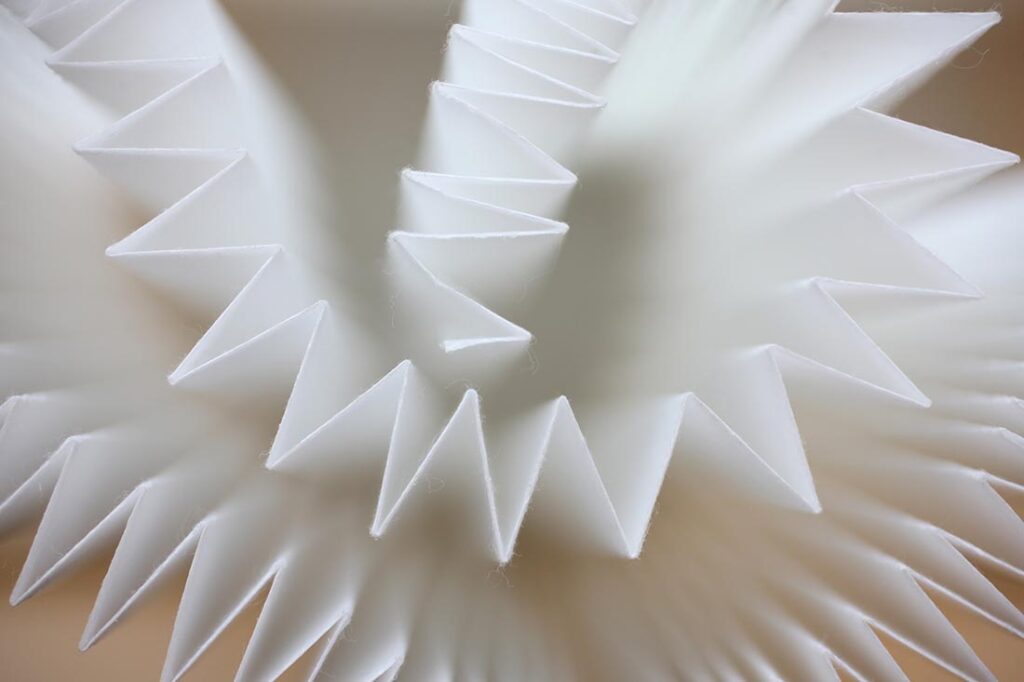

Rensa Filtration’s Advanced HEPA Filters Certified to Meet the UL 900 Safety Standards

Rensa Filtration, a leading manufacturer and distributor of consumable, mission-critical air filtration solutions, announced that its SuperFlo HEPA V-Bank and HEPA Deep Pleat filters have been evaluated by UL Solutions to meet the requirements of the UL 900 Standard for safety for Air Filter Units. The UL Mark underscores Rensa’s commitment to providing safe, high-quality filtration products and confirms that these filters have undergone rigorous third-party testing and verification by UL Solutions.

Brandon Ost, CEO and Founder of Rensa Filtration, said, “We’re excited that our SuperFlo HEPA V-Bank and Deep Pleat filters now have UL 900 Classification. These filters are essential for critical industries like data centers, healthcare, and advanced manufacturing, where high-performance air filtration is critical. Our ongoing investment in our offering of HEPA filters helps us stay at the forefront of the air filtration industry.”

Rensa SuperFlo HEPA V-Bank and Deep Pleat filters are engineered to perform in adverse, critical, and sensitive conditions. These filters provide superior performance with high dust-loading capacity and low resistance to airflow, offering 99.97% and 99.99% efficiency at 0.3 microns. Constructed with a 40% lighter high-impact plastic frame and our proven mini-pleat technology, they deliver superior filtration, resulting in enhanced performance, improved energy efficiency, and a lower total cost of ownership.

Parker Launches Automated Solution for PUPSIT Integration

Parker Bioscience Filtration, a division of Parker Hannifin, the global leader in motion and control technologies, announces the launch of SciLog® NFF+ PF. This innovative solution is specifically designed to assist biopharmaceutical manufacturers in seamlessly integrating Pre-Use Post-Sterilization Integrity Testing (PUPSIT) into their filtration processes, ensuring the highest standards of product safety and quality.

The SciLog® NFF+ PF system addresses the complexities of implementing PUPSIT in biopharmaceutical manufacturing environments. This fully automated, multipurpose Normal Flow Filtration (NFF) system features an on-board PUPSIT solution and is designed with a compact footprint, making it ideal for Good Manufacturing Practice (GMP) operating environments.

In response to the updated EU GMP Annex 1 guidelines, PUPSIT—an essential procedure for verifying the integrity of sterilizing filters before use—has become mandatory in most sterilizing filtration applications. This requirement is integral to quality risk management strategies aimed at validating filter integrity prior to its application.

However, the implementation of PUPSIT can introduce increased risks, such as a higher number of connections and elevated operating pressures, which can lead to human error and necessitate additional operator training. Operational errors can result in product waste, potentially affecting supply chains.

To mitigate these challenges, Parker has integrated single-use flow paths, advanced sensing technology, and automation within the SciLog® NFF+ PF system. This design guides operators through the PUPSIT process and overall bioprocessing via an intuitive interface, significantly reducing the risk of human error. Operators can configure fully automated sequences to monitor, adjust, and record pressure and flow rates, optimizing processing times and maximizing filter life and efficiency. The system executes the sterile filtration sequence, with PUPSIT seamlessly integrated as a key step in the process, ensuring filter integrity is validated prior to product filtration.

Grundfos joins Water Resilience Coalition

Grundfos, a world leader in pumping solutions and water technology, announced that it is joining the Water Resilience Coalition – a CEO-led initiative driving corporate action on water stress.

The Water Resilience Coalition is an initiative of the CEO Water Mandate, a partnership between the Pacific Institute and the United Nations Global Compact. By 2030, the Coalition aims to unite a critical mass of companies to build water resilience in their operations and supply chains, while also investing in collective action to improve water resilience in 100 Priority Basins, the most water-stressed basins in the world.

The Water Resilience Coalition now has 40 leading companies as members, collectively representing a market capitalization exceeding US$5 trillion.

Ahlstrom Leading the Way in Lignin-Based Filtration Solutions

Ahlstrom, a global leader in fiber-based specialty materials, enhances its offering for its patented lignin-based filtration media. A proven, high-performance alternative to traditional filtration materials further supports customers in making sustainable choices.

Ahlstrom ECO™, introduced in 2023, combines a proprietary lignin-based impregnation, replacing fossil-based resin with a renewable, bio-based cellulose filtration media. This innovation significantly reduces reliance on non-renewable resources while maintaining exceptional durability, mechanical strength, and filtration performance.

Designed for liquid and air filtration, Ahlstrom ECO™ is ideal for engine oil and engine air intake filtration, as well as for industrial filtration systems operating under challenging conditions. By delivering superior filtration performance, it helps optimize equipment protection while contributing to a lower environmental impact.

According to Ahlstrom’s estimates, the lignin-based impregnated filter media displays a lower carbon footprint than a standard fossil-based resin media. Additionally, the lignin-based impregnation brings a significant reduction, between 50–70% of formaldehyde emission during the curing process. This makes it an industry-leading choice for manufacturers seeking to improve sustainability without compromising performance or reliability. Additionally, a flame-retardant version is available for air filtration applications requiring enhanced fire safety.