In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: December 12, 2024

New Microplastics Water Filter Made With Cotton and Squid Bone Could Be 99.9% Effective

In a new study led by researchers at Wuhan University, scientists have developed a filter, made with cotton and squid bone, that can be used to adsorb certain microplastics in aquatic environments, and they determined the filter was 98% to 99.9% effective in filtering microplastics.

The study, published in the journal Science Advances, explored the development of a foam filter made with cellulose, from cotton plants, and chitin, a type of natural biopolymer found in the exoskeletons of arthropods and mollusks, as well as in some cell walls of fungi and algae, according to Science Direct. Both cellulose and chitin are considered “two of the most abundant polysaccharides found in nature,” according to the study, and they are already used frequently for removing larger pollutants from wastewater.

The researchers are applying the use of cellulose and chitin in a novel way to tackle microplastic pollution in water, which has typically been addressed with magnets, surface-engineered adsorption methods or coagulation methods, all of which can be difficult and expensive to scale.

Eaton Names Pete Denk President and COO, Industrial Sector

Eaton announced that Pete Denk has been named president and chief operating officer, Industrial Sector, effective January 1, 2025. Denk succeeds Paulo Ruiz, who will assume the role of president and chief executive officer following Craig Arnold’s retirement on May 31, 2025. In this role, Denk will be responsible for the company’s Aerospace, Mobility, Filtration and Golf Pride businesses. He will continue reporting to Ruiz as a member of Eaton’s senior leadership team. In a related move, Antonio Galvao will succeed Denk as president, Mobility Group, effective January 1, 2025.

Denk joined Eaton in 2018 as president, Vehicle Group, North America before becoming president, Mobility Group, in 2023. Prior to Eaton, Denk spent nearly 20 years with Robert Bosch LLC, starting in manufacturing and operations and then serving in a variety of other roles of increasing responsibility including director, Development and Applications Engineering; vice president, Thermal Systems; and president, Electrical Drives, North America.

Ahlstrom Unveils New PFAS-Free Filtration Media for Air-Oil Separation

Ahlstrom, a global leader in innovative filtration solutions, has introduced a groundbreaking PFAS-free filtration platform with water-repellent properties specifically designed for air-oil separation applications. This new solution offers filter manufacturers a sustainable alternative to meet stringent regulatory and performance demands while maintaining durability and reliability.

The air-oil separation market requires high-performance materials capable of efficiently separating fine oil and water aerosols from air streams while maintaining excellent filtration performances. In multilayer filter structures, media treated with water-repellent properties enhances the coalescing effect. This ensures the media remains stable, avoiding increased wet pressure drops and preserving filtration efficiency. Traditionally, these challenges were addressed using PFAS-based technologies. Ahlstrom’s PFAS-free filtration materials eliminate the need for fluorochemicals, delivering advanced water-repellent properties that ensure reliable and robust performance, even in demanding operating conditions. A dedicated test bench supports the development and qualification of our multi-layer air-oil separation solutions in collaboration with our customers.

“Our new PFAS-free solution underscores our commitment to innovating sustainable solutions, supporting the transition to environmentally responsible alternatives without compromising performance,” says Tamara Quatrano, Vice President, R&D and Product Development, Filtration. “We are actively collaborating with our customers’ R&D teams to further develop and optimize PFAS-free filtration media.”

The PFAS-free filtration media is now available through Ahlstrom’s glass microfiber production platform in Fabriano, Italy, and is designed for use in industrial applications and sectors.

Camfil to Open New Air Filtration Solutions Facility in India

Camfil India, a subsidiary of the Swedish Camfil Group, announced the opening of its expanded production plant in Manesar, India to strengthen its capacity for providing air purification technologies.

The Camfil Group hopes the new facility will solidify Camfil India’s position as a key player in global markets and as a local sourcing hub. The new facility’s expanded production capabilities for high-performance air filters for HVAC systems will allow it to provide heating, ventilation and AC systems solutions to its clients.

The opening of the Manesar site is in line with Camfil’s long-term plan to increase local manufacturing, improve product offerings, and implement technology. The facility will also produce mini pleated HEPA filters called Megalams, which are used in the pharmaceuticals and healthcare sectors, as well as in medical and microelectronics. These filters offer a high performance, energy savings, and adherence to industry regulations.

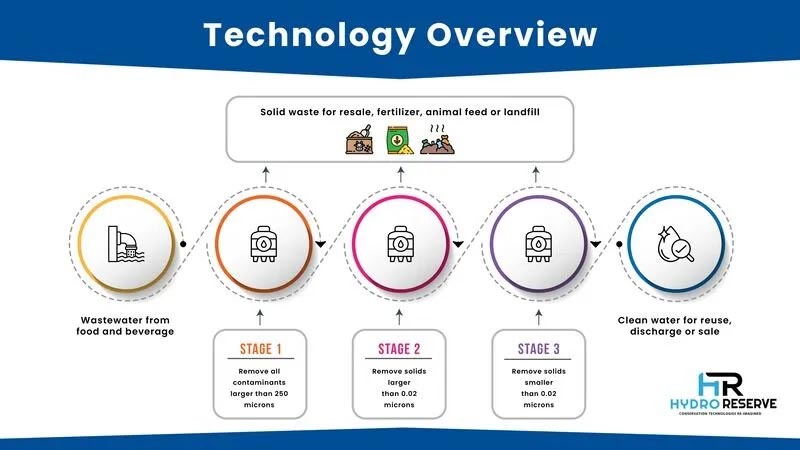

Hydro Reserve Unveils Revolutionary Mechanical Filtration Technology for Wastewater Treatment

Hydro Reserve, an innovator in wastewater management, is transforming the industry with its groundbreaking mechanical filtration technology, a unique, chemical-free solution delivering unparalleled efficiency in industrial wastewater treatment. This disruptive approach is setting new standards for environmental compliance, operational efficiency, and sustainability.

Unlike conventional wastewater systems that rely on biological processes or chemical additives, Hydro Reserve’s proprietary mechanical water filtration technology achieves 98-99% BOD reduction while bringing Total Suspended Solids (TSS) and Fats, Oils, and Grease (FOG) to non-detect levels. This innovative solution eliminates costly surcharges, reduces energy consumption, and simplifies operational processes-all while delivering superior results.

“Our system is not just a step forward; it’s actually quite a leap,” said Alex Argento, President of Hydro Reserve. “We’ve developed a one-of-a-kind mechanical solution that addresses some of the industry’s toughest challenges, ensuring compliance and sustainability without compromising efficiency.”

Hydro Reserve’s systems are designed with flexibility in mind, with standard systems accommodating flow rates between 50 GPM – 1000 GPM, all within a compact footprint and without the need for bulky holding tanks. The modular design ensures scalability, making the technology suitable for a variety of industries, including food and beverage, produce washing, dairy processing, and meat, egg and poultry operations.

By converting contaminants into a solid cake layer and reclaiming the clean water for reuse, Hydro Reserve not only meets but exceeds environmental standards. The system significantly reduces hauling costs and energy use, helping businesses achieve their sustainability goals while allowing for the reuse or sale of the separated biosolids.

Amazon Filters Launches High-Temp Vent Filter for Pharma and Biotech

A UK process filter manufacturer Amazon Filter has launched an enhanced high-temperature-resistant membrane product aimed at vent applications across the global pharmaceutical and biotechnology markets.

Amazon Filters’ SupaPore TMB is specifically designed for hot operating conditions in processes such as sterile air venting and large-scale fermentation. It is suited for use in vent housings such as on water for injection tanks or fermentation inlet air where filters are subject to continual high temperatures from heating jackets.

Features of SupaPore TMB include polyphenylene sulphide membrane support and drainage layers, which provide robust resistance to oxidative and ozonated environments.

“There are a wide range of high-flow filtration processes in pharma and biotech that require sterilization of air or other process gases to remove the risk of microbiological or particulate contaminants, said Mafalda Silva, Amazon Filters’ Market Manager for Pharmaceutical & Healthcare.

“SupaPore TMB is the latest addition, ideal for meeting the requirements of high-flow rates and low pressure drops and offering consistent and reliable performance in demanding production environments. It is capable of withstanding raised temperatures that otherwise harm standard polypropylene membranes through accelerated oxidation, particle shedding and contamination.”

EDANA Announces FILTREX™ 2025

EDANA, the leading global association serving the nonwovens and related industries, announced the upcoming FILTREX™ 2025 conference and tabletop exhibition. This premier event for filtration professionals will take place on 25-26 March 2025 at the Hilton Waterfront Hotel in Vienna, Austria.

FILTREX™ Europe serves as a pivotal platform, bringing together experts, technical specialists, and industry leaders from across the filtration supply chain. The two-day conference will focus on technological and sustainability innovations, aiming to enhance media and filter performance and highlight their role in reducing emissions. Attendees can look forward to a comprehensive program featuring presentations on the latest market trends, innovative filter materials, advancements in media design, and developments in air and liquid filtration.

The event will feature two renowned keynote speakers: Dr.-Ing. Frank Möbius, Senior Innovation Advisor at UnternehmerTUM, and Former Head of Technology Management and Forecast at BMW Group, sharing insights on open innovation, and Dr. Pero Mićić, Founder and CEO of FutureManagementGroup AG, discussing strategies to future-proof businesses.

Additionally, key industry leaders in the filtration industry from Ahlstrom, Freudenberg, and Hollingsworth & Vose will introduce pivotal topics during the roundtable discussions. Attendees will benefit from five focused sessions covering Trends and Technologies, Standards and Testing, Media Innovation, Sustainability, and PFAS-free advancements.

In conjunction with the conference, a tabletop exhibition will showcase cutting-edge products and services, providing delegates with valuable networking opportunities. The event will also feature the esteemed 4th edition of the FILTREX™ Innovation Award, recognizing outstanding achievements in nonwoven-based filtration products. Last edition, HycuTEC (inline charging technology) by Oerlikon Nonwoven, won the coveted prize after receiving over one third of the votes. Companies interested in participating in the award competition are encouraged to review the eligibility criteria and submit their applications accordingly.

Altus Capital Partners Acquires Air Innovations, LLC

Altus Capital Partners, an investment firm focused on middle market manufacturing companies, announced the acquisition of Air Innovations, LLC, a manufacturer of environmental control units for manufacturers and distributors in the wine, aerospace, semiconductor, homeland security, and healthcare markets. The Company provides custom-built solutions and has a broad portfolio of branded standard products for the industries it serves. Financial terms of the transaction were not disclosed.

Headquartered in North Syracuse, NY, Air Innovations’ ECUs are used in high-cost-of-failure applications such as sterile storage cabinets in hospitals, clean room semiconductor lithography equipment, and payload protection for spacecrafts. The Company’s Wine Guardian brand offers a wide variety of ECUs for use in homes, restaurants, and wine storage facilities that require commercial-grade temperature and humidity control. Air Innovations has a proven track record of commercializing its proprietary and customized systems to offer solutions to meet each individual customer’s specific needs. Air Innovations’ experienced management team will remain unchanged.

H2O Innovation Announces Agreement with MegaVessels Water Inc., Harbin ROPV Industrial

H2O Innovation Inc. has entered into an agreement with MegaVessels Water Inc. and Harbin ROPV Industrial Co. Ltd., granting the corporation an exclusive license to manufacture and sell the Mega-Vessel Membrane System for Reverse Osmosis (RO) applications worldwide. The emergence of mega-vessels technology marks a significant breakthrough in the field of desalination, driven by several key factors that enhance efficiency, capacity, and sustainability.

The simplified design of MegaVessels contributes to its reliability. By minimizing the number of fittings, piping, and connections required in an RO system, they not only enhance overall system reliability but its ease of maintenance. It allows the reduction of membrane cleaning frequency, shortening installation time, and simplifying system fabrication, assembly, and maintenance.

It is prioritizing energy savings so RO plants can simultaneously reduce costs, minimize environmental impact, and improve overall performance, making them more sustainable and economically viable in the long run.