In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: January 23, 2024

Ahlstrom Plans to Invest in a New Production Line for Molecular Filtration Media

Ahlstrom pursues its over 50-year commitment and drive of the future of the global filtration industry by investing in a new production line for molecular filtration media in Turin, Italy.

Air quality in closed environments such as buildings and vehicles is a major concern in many areas of the world. In this context, particulate filter media play an important role in removing solid particles and aerosols from the air. Molecular filter media are used in complement, removing gaseous pollutants, including volatile organic compounds, inorganic gases (such as sulfur dioxide, nitrogen oxides, ammonia), and odors, and delivering the cleanest air to people and processes.

The new line is being designed to produce the highest-performance adsorbent materials for premium filtration applications, including next-generation cabin air and fuel cell air intake, as well as a complete range for HVAC and cleanrooms. It will enable Ahlstrom to offer superior solutions for customers and support their industrial filtration application development as well as the transition to electric vehicles.

The investment is made in synergy with Ahlstrom’s Fine Fiber platform in Turin, which will be upgraded to produce HEPA filtration layers. Fine Fiber media can be combined with molecular filtration materials also to deliver the best protection against the finest particles.

Metso Inaugurates New Screening Media Factory in Irapuato, Mexico

Metso celebrated the inauguration of its screening media factory in Irapuato, Mexico, on January 17, 2024. The new factory will significantly increase Metso’s supply and delivery capabilities for mining and aggregates customers in North and Central America.

The screening media center employs 46 people and is located on a 9,000+ m2 lot. The new screening media factory uses advanced and sustainable manufacturing practices, and the installed solar panels will cover approximately 50% of the needed electricity.

“We are very pleased to officially inaugurate our new screening media factory in Irapuato. This milestone is yet another indication of our deep commitment to customer success. The Irapuato region is an important center of excellence for high-quality products for our mining and aggregates customers. All our factories are modern and focused on safety, employee wellbeing, and continuous development,” says Alfredo Monreal, Vice President, Sales and Service, Mexico and Central America, Metso.

Metso’s screening installed base in the Americas has grown significantly: last year alone Metso delivered a total of 250 new screening machines to mining and aggregates customers.

Today, Metso has approx. 730 employees working in production, sales, and field service in Mexico.

In the same industrial area in Irapuato, Metso also has a new rubber and Poly-Met media factory. Construction of a new polymer filter plate factory will be finalized during 2024, and the factory will be operational in early 2025.

Metso’s screen offering consists of banana screens, horizontal screens, inclined screens, mobile screens, portable screens, and ultrafine screens. With screening media solutions that range from rubber and polyurethane to classic wire, Metso offers versatile screening media systems for a wide range of screening applications. Discover more about Metso’s screening offering on our website.

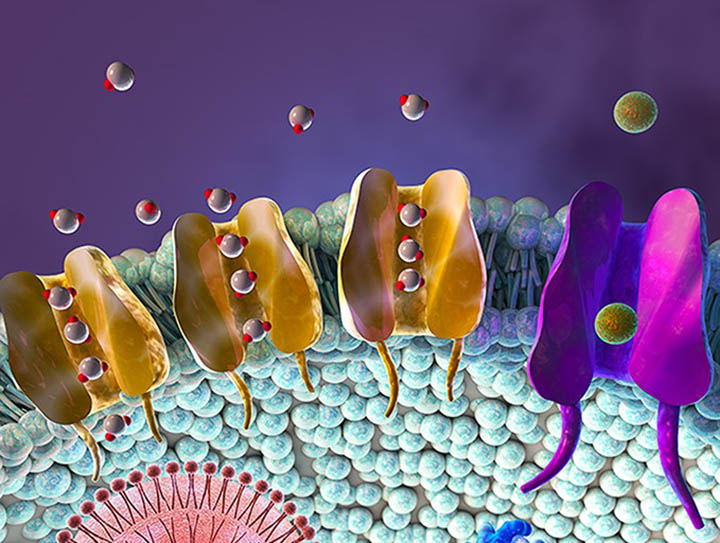

UK Aston University to Establish Institute for Membrane Excellence

United Kingdom Aston University will establish the Aston Institute for Membrane Excellence (AIME), a globally unique, cross-disciplinary institute to develop novel biomimetic membranes, after receiving a major grant of £10m from Research England.

AIME will be led by Professor Roslyn Bill, from the School of Biosciences, with co-lead Professor Paul Topham from the department of Chemical Engineering and Applied Chemistry (CEAC).

Membranes, both biological and synthetic, are hugely important in many sectors. For example, the world’s top ten selling human medicines all target proteins in biological membranes, while synthetic polymer membranes are used in the US$100bn/year water purification industry. The team behind AIME believes that the full potential of membranes will only be realized by an interdisciplinary group spanning biology, physics and chemistry that can investigate membranes holistically.

Pall Corporation Introduces SepraLYTE™

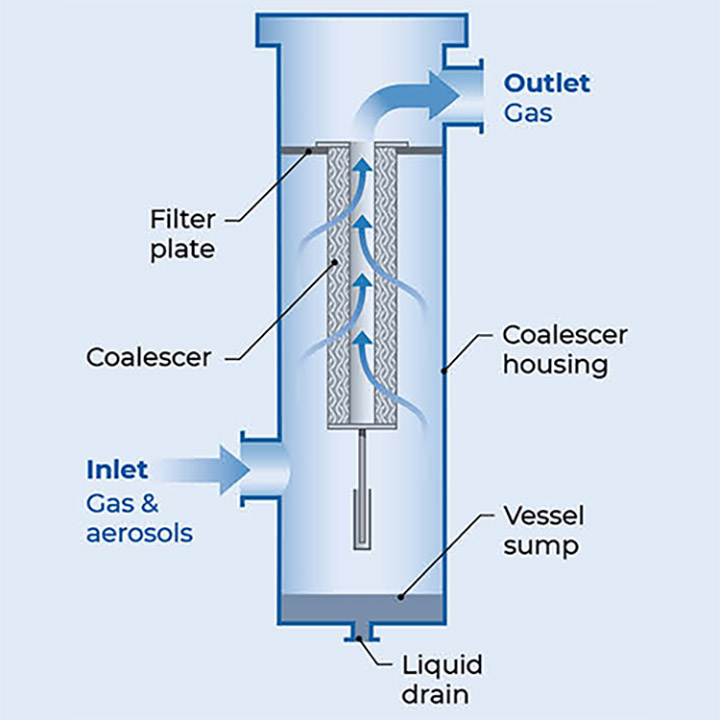

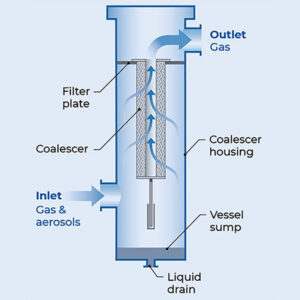

Pall Corporation, a leading provider of filtration, separation and purification solutions, has introduced SepraLYTE™ liquid/gas coalescers, an innovative solution designed to meet the increasing demand for efficient separation of electrolyte aerosols from gas in green hydrogen production processes.

Leveraging advanced separation technology, SepraLYTE coalescers excel in the separation of water or electrolyte aerosols (30% potassium hydroxide solution) from hydrogen, ensuring the purity of hydrogen produced from electrolysis processes. They are highly suitable for a wide range of separation applications where minimal pressure drop is crucial for downstream processes.

These coalescers feature Pall’s proprietary melt blown media technology, which achieves outstanding liquid mist separation with low differential pressure. The compact design incorporates coalescer media that ensures compatibility with various chemical applications. Other key advantages of SepraLYTE liquid/gas coalescers is their ease of maintenance, compact size and waste reduction.

Utilizing SepraLYTE liquid/gas coalescers, customers gain significant advantages over conventional separation products. These advantages include reliable, consistent, and verifiable separation performance, high gas flow and liquid removal in a compact cartridge, which allow for smaller systems with low capital, operating, and maintenance costs.

Filter King LLC Announces Opening of 100,000 Square Foot Manufacturing Facility

Filter King LLC, a leading manufacturer of HVAC home and business air filters, announced the opening of a new manufacturing facility in Miami, Florida. The 100,000 square foot facility, which includes production, warehousing, and distribution, as well as the Company’s corporate headquarters, was precipitated by surging demand for its premium quality air filters, and high growth expectations for 2024 and beyond.

“We’re proud to continue our history of manufacturing excellence in South Florida,” said Rick Hoskins, Founder and CEO of Filter King. “This is an opportunity to expand our manufacturing capacity to meet the Company’s growing market share regionally and nationwide, and to support the local economy and workforce by bringing many more jobs to the area.”

Mr. Hoskins further stated, “Our goal at Filter King is to make best in class air filters at competitive prices, achieve rapid delivery to the customer, and to accommodate any size filter needed, be it custom or standard.” In December, Filter King produced over 3,800 different sizes of custom and standard HVAC air filters, showcasing the Company’s bespoke manufacturing capabilities.

Filter King’s products are sold through multiple channels, including, direct-to-consumer (D2C) e-commerce marketplaces and filterking.com, as well as commercial sales to condominiums, property management companies, schools, hospitals, government facilities, and HVAC service providers.

GEA Starts Operations at New $20m Facility in Wisconsin

GEA has started operations at its recently inaugurated facility in Janesville, Wisconsin, US, spanning 86,000-square-feet and dedicated to fabrication, repair, logistics and training.

With an investment of $20 million, the facility aims to cater to the increasing needs of GEA’s expanding customer base in the US Midwest.

The site’s production capabilities are focused on the finalization of separators, decanter, valves and pump assembly. The facility has incorporated several features designed to boost sustainability, such as solar panels, water reuse systems and a building management system.

Azam Owaisi, CEO of GEA North America, said: “Opening the new Janesville facility as anticipated in December 2023 represents a significant step toward meeting our customers where they operate. It highlights GEA’s commitment to product quality and service excellence. We are excited to become a vibrant employer and partner for the Janesville community.”

Call for WOW Papers

INDA announced a Call for Presentations for the 2024 World of Wipes® International Conference. World of Wipes (WOW) is organized and presented to the nonwoven fabrics industry by INDA, Association of the Nonwoven Fabrics Industry. Presentations at WOW will focus on a series of market and technical topics (listed below) to provide opportunities for industry leaders to review the latest research, product innovation, and market applications for all wiping products and their components. WOW will target end use wipe manufacturers, converters, and their suppliers.

Presentations are for the following key themes:

- Dry and wet wipes

- Circular economy

- Sustainability / End-of-life implications

- Substrate formation

- Skin care formulations

- Raw materials

- Packaging

- Machinery and equipment

- Market trends and consumer insight

- Regulations

- Ecommerce / Retail channels

The deadline for submitting papers is Friday, January 26, 2024. The conference takes place June 17-20, 2024, at Hyatt Regency Minneapolis, Minneapolis, Minnesota.

Trojan Technologies to Sell Salsnes Filter Business

Trojan Technologies announced their plan to sell the Salsnes Filter business to current and former members of the Salsnes management team, with an anticipated closing of the transaction in mid-January 2024. Following the closing, Salsnes Filter will be a standalone organization and no longer an affiliate of Trojan Technologies.

The transaction will provide Salsnes-Filter with the opportunity to reinvest further in their solids separation filter technology to better serve the demands of the water treatment industry.

Since 1991, Salsnes has been offering their solids separation filter technology and pursuing research, product development, testing, and quality initiatives. This focus and dedication have produced a highly efficient and reliable filter that maximizes solids separation, while dramatically decreasing costs including capital, operating, maintenance and land. With installations around the world and in a variety of municipal and industrial applications, the Salsnes Filter system is synonymous with eco-efficient solids separation technology. Salsnes Filter will remain at its current production facility in Salsnes Norway.

Atlas Copco Names New CEO

Atlas Copco has named Vagner Rego new president and CEO, effective May 1, 2024. He will replace Mats Rahmström who has requested to leave his position after leading the Group since 2017.

Rego, currently senior executive vice president and president of the Compressor Technique business area, joined the Group in 1996 as a trainee engineer in his native country Brazil. A decade later he was appointed Business Line manager for Compressor Technique Service in Brazil and in 2010, he became vice president of Marketing and Sales for the Compressor Technique Service division, based in Belgium. He has also been general manager for Power Technique’s Customer Center in Brazil. Before he took on his current position in 2017, he was president for the Compressor Technique Service division.

Rego has a degree in mechanical engineering from Mackenzie University and an MBA from Ibmec Business School, both located in Brazil. Rego will be based in Stockholm, Sweden.

FILTECH 2024: Call for Papers

The world’s largest filtration event, FILTECH, has issued a call for papers for the conference scheduled for November 12-14, 2024, in Cologne, Germany.

The FILTECH 2024 Conference will feature the latest advances and techniques in liquid/solid and gas/particle separation (dust, gas & air filtration) during three days of in-depth exposure. Technology and know-how transfer is a main target.

Industry professionals are invited to present their latest research at the conference to an international audience and network with filtration experts from all over the world. Deadline for submitting abstract is May 31, 2024. More than 200 presentations are planned for the event. Topics copvered are:

- Solid-Liquid-Separation

- Solid-Gas-Separation

- Filter Media

- Testing; Instrumentation; Control

- Simulation and Modeling

- Product Related Processes

- Membrane Processes.

New Leadership for Mann+Hummel’s Air Filtration and Water Membrane Solutions

As of April 1st, 2024, MANN+HUMMEL has appointed Henk in ’t Hof as President Life Sciences & Environment (LS&E). In his role, in ‘t Hof will be responsible for MANN+HUMMEL’s global Air Filtration and Water Membrane Solutions business. He will report directly to Kurk Wilks, President and CEO of the MANN+HUMMEL Group.

The Dutch-born in ‘t Hof has over 30 years of experience in various leadership positions at Philips, Hayco Group and Newell Brands. Most recently he was employed as global CEO for Water and Air Wellness at Unilever based out of Hong Kong.

Henk in ‘t Hof succeeds Fua Nipah who is leaving the company in order to pursue his career outside the company.

U.S. Water Utilities Deploy PFAS Treatment Technologies to Safeguard Drinking Water

As U.S. and European lawmakers tighten restrictions on toxic PFAS contaminants in water, utilities and businesses are working to safeguard drinking water supplies for communities. Often referred to as “forever chemicals,” PFAS are widely used, long lasting chemicals whose components break down slowly over time.

PFAS chemicals are human-made but have become widespread in some water sources across the country and can have potentially harmful effects on human and animal health. Latest estimates from the U.S. Environmental Protection Agency’s (EPA) monitoring program show that one in four public drinking water systems contain PFAS concentrations at or above minimum reporting levels.1

Xylem is working with municipal and industrial customers to address this challenge, with more than 80 PFAS mitigation installations in the U.S. alone. Among the states where Xylem is working are Colorado, Maine and California.

Army Installs More Water Filtration Systems in East Selah

The U.S. Army has installed systems to filter forever chemicals out of drinking water at six homes in East Selah, Washington, with three more filtration systems on the way.

The filters are part of remedial actions taken by the Yakima Training Center to address the groundwater contamination in the area caused by center operations. For years, the Army used a firefighting foam rich in per- and polyfluorinated substances, a family of chemicals hazardous to humans.

Over time, the chemicals in the foam seeped into the ground and contaminated the groundwater on and around the base, including parts of East Selah. Since 2021, the Army has provided bottled water to households where the level of contamination met the federal standards for receiving aid.

Tampa, Florida New Water Filtration System is Expected to Help Remove PFAS

The U.S. Environmental Protection Agency is expected to officially set limits on six so-called forever chemicals, known as PFAS, in drinking water. One community that has seen elevated levels of two of these forever chemicals is Tampa, Fla. And now the city says it will likely be the first in the country to bring in a new technology that will make it easier to filter out these PFAS.

Tampa is still in the designing phase, and the system won’t be completed until about 2032. But Tampa’s more than 700,000 water customers are already paying for it. It’s expected to cost $200 million, and it’s part of a larger infrastructure improvement plan that the city council already approved, so their water bills will be increasing every October until 2040. That said, city officials do point out that the technology will actually save the department nearly a million and a half dollars a year, according to NPR.

Camfil APC Unveils Comprehensive Resource for Dust Collection in Battery Manufacturing

Camfil Air Pollution Control (APC), a global leader in industrial dust, fume and mist collection, recently announced the launch of a critical new resource for battery manufacturers: “A Guide to Dust Collection in Battery Manufacturing.” This comprehensive guide addresses the often-overlooked need for efficient dust collection in the rapidly growing battery manufacturing industry, crucial for both environmental and worker safety.

Battery manufacturing processes release toxic dust particles, including lead, nickel, cobalt and aluminum, posing significant health risks like lead poisoning and potential for explosive incidents. Camfil APC’s guide provides insights into managing dangerous dusts produced during the manufacturing of various batteries, such as rechargeable auto batteries, electric vehicle (EV) batteries and lead-acid batteries.

The guide highlights the health hazards associated with exposure to various toxic dusts like lithium, cobalt, nickel and manganese, emphasizing the need for stringent dust control measures. It outlines the various stages of battery manufacturing that pose lead exposure risks, including oxide and grid production, plate processing, battery assembly, and repair and reclaim operations.