In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: June 28, 2024

Ahlstrom Introduces a New Range of Filtration Materials

Ahlstrom is leading the marketplace towards more sustainable, fluoro-free solutions for fiber-based solutions. This week, Ahlstrom extended its innovative fluoro-free technologies into a wide range of industrial air filtration applications to support filter manufacturers in creating products with long-lasting filtration performance without the use of fluorochemicals.

Ahlstrom’s new fluoro-free filtration materials are ideal for gas turbine air intake, air pollution control, heating, ventilation, and air conditioning (HVAC) applications. The new range of materials offers water-repellent properties, which increase the durability and stability of the final filter in wet conditions. In global filtration markets, hydrophobic properties are essential to maintaining the highest filtration performance in challenging environments.

In air pollution control applications, for example, hydrophobic materials save energy by limiting the pressure drop increase in humid conditions. Specifically, in gas turbine applications, water repellency prevents liquid water ingress and dissolved salt penetration through a filter, protecting the turbine from corrosion.

www.ahlstrom.com

Air Products Membrane Solutions Breaks Ground on $70 Million Expansion in Missouri

Air Products, the global leader in the production of gas separation and purification membranes, hosted a groundbreaking event at the site of a $70 million expansion of its Missouri Manufacturing and Logistics Center in Maryland Heights, near St. Louis, Missouri.

The investment, which is Air Products Membrane Solutions’ largest ever, is driven by growing product demand in biogas and hydrogen recovery applications, as well as customer needs for the use of nitrogen for the aerospace industry and cleaner fuels for the marine industry.

“We are excited to officially break ground on this important project. This expansion builds on our commitment to be a leader in the energy transition,” said Dr. Erin Sorensen, general manager, Air Products Membrane Solutions. “I share in our local team’s excitement for today’s event and in the promise of what this new facility will mean for our business and our customers as we continue to work together to generate a cleaner future.”

The new manufacturing facility is expected to be in production by the end of 2025 and include the addition of 30 new full-time positions. Currently, about 170 employees work at the St. Louis facility. This expansion follows a previous $10 million investment made in 2023 to increase production capacity at the current facility.

Air Products Membrane Solutions specializes in the development of hollow fiber membrane separators and systems for onsite gas generation. Air Products designs, engineers, manufactures, and markets a full portfolio of PRISM® Membrane Separators, Marine Systems, and Engineered-to-Order Systems to protect lives and goods at sea, on land, and in the air. Air Products’ systems are also designed to create more sustainable energy sources and raise productivity across a variety of industries and applications.

Metso to Deliver Thickeners, Filters to Mine Water Treatment Project in Peru

Metso has been awarded with a contract to deliver several thickeners and filters to a mine water treatment project in Peru. The value of the order is approximately EUR 15 million, and it has been booked in the Minerals segment’s 2024 second-quarter orders received.

Metso’s scope of delivery includes several High-Rate Thickeners operating in a High Density Sludge (HDS) mine water treatment application and automatic EBS Series Liquid Filters with an electric self-cleaning mechanism for ultra-fine filtration. The thickeners, which are part of Metso’s Planet Positive offering, include the ReactorwellTM feed system and are specially designed bolted stainless-steel construction for high corrosion resistance and fast installation.

“We are pleased to continue working with this important customer in Peru to support their needs in mine water treatment with our Planet Positive thickening solutions. The environmentally sound high-rate thickeners will have an important role in ensuring a reliable operation and meeting the customer’s project criteria for high performance, fast installation and low maintenance,” says Brian Berger, Vice President, Thickening and Clarification at Metso.

Mann+Hummel: Hasmeet Kaur to lead Global Transportation Division

MANN+HUMMEL, a global leader in filtration solutions, has appointed Hasmeet Kaur as President Transportation. MANN+HUMMEL offers innovative filtration solutions for both original equipment and aftermarket. In addition, manufacturers of construction and agricultural machinery, rail vehicles, ships, and energy technology are also among the customers of advanced MANN+HUMMEL filtration technologies.

In her new role, Hasmeet Kaur will report directly to President and CEO Kurk Wilks. As President of the Transportation division, she steers the activities of the Original Equipment unit, consisting of the Passenger Car and Heavy Duty on- and off-road and Industrial businesses, as well as the Automotive Aftermarket unit.

Hasmeet Kaur joins MANN+HUMMEL from Roland Berger, where she was a Global Managing Director as well as Member of the Board. In addition to these responsibilities, she also headed the global Research Department and Roland Berger Institute. During her eleven years with Roland Berger, she executed projects for over 75 global automotive companies across 25 countries. Hasmeet Kaur has been responsible for driving the consultancy’s Automotive Aftermarket Business in EMEA, with a focus on holistic business growth and transformation strategies as well as operational efficiency. She holds an MBA in Finance from the S.P. Jain Institute of Management and Research, and a Master of Science in Biochemistry from the Panjab University.

Donaldson Company Announces Leadership Role Changes

Donaldson Company, Inc., a leading worldwide provider of innovative filtration products and solutions, announced the following leadership role changes effective August 1, 2024:

- Andrew Dahlgren, 53, currently President, Life Sciences is appointed President, Mobile Solutions.

- Richard Lewis, 52, currently President, Mobile Solutions is appointed President, Life Sciences.

“As we execute on our strategic initiatives and make progress toward our fiscal 2026 financial targets and 2030 sustainability ambitions, we are taking steps to ensure Donaldson maintains leadership depth and agility across the organization,” said Tod Carpenter, Chairman, President and CEO.

Dahlgren, prior to his current role, was Vice President, Asia Pacific. He joined Donaldson in 1994 and throughout his tenure has held leadership positions including Vice President and General Manager of various business units in both Mobile and Industrial Solutions. Dahlgren holds a bachelor’s degree in mechanical engineering from the University of Minnesota Institute of Technology and an MBA from the University of Minnesota Carlson School of Business.

Lewis, prior to his current role, was Senior Vice President, Global Operations. He joined Donaldson in 2002 and throughout his tenure has held several Operations leadership positions as well as General Manager in Mobile Solutions. Lewis holds a bachelor’s degree in industrial engineering from the University of Louisville and an MBA from Indiana University.

Waterise and Jordan Phosphates Mines Company Announce Partnership for Innovative Deep Sea Desalination

Jordan Phosphates Mines Company (JPMC), one of the world’s largest phosphate producers, announced a strategic partnership with Waterise, a pioneering Norwegian start-up specializing in deep sea environmentally friendly desalination. Together, they will embark on an ambitious deep sea desalination project in the Gulf of Aqaba to meet the increasing water demand at JPMC’s facilities. The two parties are currently working to secure the water off-take arrangements and other pertinent details before executing the definitive agreements.

This landmark collaboration aims to leverage Waterise’s state-of-the-art desalination solution to sustainably support JPMC’s water needs, contributing to the company’s operational efficiency and environmental sustainability goals.

JPMC’s Chairman, H.E. Dr. Mohammed Thneibat, echoed this sentiment: “This partnership with Waterise aligns perfectly with our commitment to sustainable development and environmental stewardship. By utilizing this innovative desalination solution, we can ensure a consistent supply of water while minimizing our ecological footprint. We look forward to seeing the positive impact this project will have on our operations and the surrounding community.”

“We are thrilled to partner with JPMC on this groundbreaking project,” said Niels Petter Wright, CEO of Waterise. “Our deep sea desalination solution based on world class oil and gas technology and marine operations represents a significant advancement in sustainable water production, and we are confident that it will provide a reliable and environmentally friendly local water supply for JPMC’s critical operations in the Gulf of Aqaba.”

Rensa Filtration Launches Family of Advanced HEPA Filters

Rensa Filtration, a pioneer in innovative air filtration products, recently launched the production of high-performance HEPA filters at its headquarters and manufacturing campus in Aurora, IL.

Rensa’s SuperFlo HEPA filters use advanced mini-pleat technology to achieve high dust loading and low resistance to airflow at 250 FPM, 500 FPM and 600 FPM compared to aluminum separator-style HEPA filters. This filter design provides HEPA level filtration with lower pressure drop, which leads to energy savings and lower cost of ownership.

Brandon Ost, CEO and Founder of Rensa Filtration, is enthusiastic about the new product line. “Our distributors have been asking us to provide a broader range of HEPA filters to supplement our MERV 11 – MERV 16 medium- and high-efficiency filters for their customers ranging from healthcare facilities to advanced manufacturing. We have made significant investments in additional HEPA filter manufacturing and testing capabilities and expanded our team of HEPA experts in the last year to support this product launch.”

Rensa offers HEPA filters rated at 99.97% and 99.99% efficiency at 0.3 microns. Each filter is tested per IEST RP CC 001.7 standards to guarantee superior performance.

HEPA level filtration is widely used to help protect people and processes in healthcare facilities and industries including pharmaceuticals, optics, battery manufacturing, semiconductors and aerospace.

MossHydro to Upgrade Membrane Filtration Systems for Norwegian Aquaculture Farm

MossHydro AS, a subsidiary of Nordic Technology Group AS, announced the signing of a commercial

contract with an Aquaculture breeder to upgrade Membrane Filtration Systems with a value of NOK 1.8 Million.

The Aquaculture breeder has built a large land-based hatchery for salmon smolt in Vestland. The facility is close to 5 acres and the pool capacity is more than 20 000 cubic meters. At the facility, there are RAS facilities for starter feeding, rearing, press smolt, smolt and post smolt. A total of 10+ million or more than 1 000 tonnes of smolts are to be produced a year.

MossHydro develops and manufactures water purification systems and filtration using proprietary

technologies. Headquartered in Drammen, Norway with manufacturing in Sweden, Switzerland and TX/USA, MossHydro have water purification systems installed globally in ships and marine operations as well as municipal water supplies and industrial applications.

Johnson Controls to sell Air Distribution Technologies

Johnson Controls, a global leader for smart, healthy and sustainable buildings, announced it has reached a definitive agreement to sell its Air Distribution Technologies business to Truelink Capital, a middle-market private equity firm based in Los Angeles.

“The sale of our Air Distribution Technologies business is the next step as we continue to simplify our portfolio and advance our transformation into a comprehensive solutions provider for commercial buildings,” said Johnson Controls Chairman and CEO George Oliver. “This transaction is consistent with our strategy to focus our resources on our most attractive opportunities for value creation. I would like to thank our talented Air Distribution Technologies employees for their hard work and dedication over the years. We are confident the business and the team will be well positioned for future success under Truelink’s ownership.”

Included in the sale are market-leading air distribution and movement brands Koch Filter, Titus, Ruskin, Krueger, PennBarry and Tuttle & Bailey and their product lines of grilles, registers and diffusers, terminal units, fire and smoke dampers, louvers, filters and fans. Air Distribution Technologies products are manufactured in the United States, Mexico, India, Thailand and the United Arab Emirates in facilities that will transfer to Truelink as part of the transaction. The Johnson Controls and Enviro-Tec brands are not included in the transaction.

The transaction is expected to close the second half of the calendar year 2024, subject to customary closing conditions. Baird served as exclusive financial advisor and Cleary Gottlieb Steen & Hamilton LLP served as legal advisor to Johnson Controls on the transaction.

Pall Opens $150 Million Facility in Singapore

Pall Corporation, a leader in filtration, separation and purification technologies, recently held its opening ceremony for a new state-of-the-art manufacturing facility in Singapore that will serve regional and global customers within the growing semiconductor industry. Pall has invested approximately US$150 million on the facility which will primarily produce lithography and wet-etch filtration, purification and separation solutions that will help meet the high demand for advanced node semiconductor chips.

“Throughout an almost 80-year history, Pall has been on the forefront of solving some of the world’s most complex challenges using advanced filtration. This new facility is not only an important development for advancing semiconductor manufacturing technology, but also an important next step for Pall. We will continue to leverage our experience and expertise to help solve global challenges, from the increased demand for advanced chips to aiding in the transition to greener manufacturing,” said Mr. Naresh Narasimhan, Danaher Group Executive, High Growth Markets & Pall Corporation.

The now-completed seven-acre facility will include more than 18,000 square meters of high-volume manufacturing (HVM) and office space and will integrate core research and development capabilities in the future. The new facility will allow customers in highly demanding industries to meet growing end market demand for data processing and storage.

It is expected that the new site will create up to 300 jobs over the next few years across science, engineering and advanced manufacturing, with an emphasis on training and developing new talent as well as enabling transfer of knowledge to contribute to the growth of the sector as part of Singapore’s long-term strategy. There will be a consistent focus on talent development aligned to broader strategic national priorities to ensure that the advanced manufacturing industry can thrive in Singapore. With the addition of Pall’s new facility, Pall is building more capacity to support cutting-edge technologies and help scale new applications like generative AI.

Hengst Filtration Acquires Canadian-American Filter Company

German filtration company Hengst Filtration is acquiring North American hydraulic filter manufacturer Main Filter, which is based in both Sault Ste. Marie, Ontario, and Lincolnton, North Carolina. Hengst described Main Filter as a “respected manufacturer of hydraulic filters for more than 35 years.” The acquisition comes three years after Hengst acquired the hydraulic filter business of Bosch Rexroth.

“We are working hard to be the most competent partner for our customers and to provide them with the best possible service. Main Filter is a crucial piece of the puzzle, especially in the North American market,” CEO of Hengst Filtration, Christopher Heine said.

According to Hengst, Main Filter has a wide range of products and is key to Hengst’s ability to supply local customers in North America through local production.

“This is a win-win for the industry and in particular, we are delighted to have partnered with Hengst, who will, as a filtration specialist, continue to provide great service and quality products for our clients. I’m confident, that the culture and leadership of Hengst, aligned with our values and long-term aspirations, will be a great home to all of our employees,” said Bill Horne, CEO of Main Filter.

New President of Original Equipment Passenger Car Unit at Mann+Hummel

MANN+HUMMEL, a global leader in filtration solutions, announced the appointment of Xu Jie (徐捷) as President of the Original Equipment Passenger Car unit. The business encompasses air and liquid filter systems for vehicles with internal combustion engine and new solutions for new energy vehicles.

Xu Jie has been with MANN+HUMMEL for 19 years, holding various leadership roles in Germany and China, including Vice President R&D for the APAC region. He studied at the University of Shanghai for Science and Technology, and speaks English, Mandarin and Shanghai dialect.

“As the Asian market plays an increasingly dominant role in the automotive industry, Xu Jie’s extensive experience in the region made him a natural choice for the newly created position,” said Kurk Wilks, President and CEO of the MANN+HUMMEL Group. “In China, an all-time high of almost 25.8 million new passenger cars were registered in 2023 – we will use the momentum to expand our position in this significant market and remain dedicated to fostering speed and customer-centricity across all segments.”

With this step, MANN+HUMMEL emphasizes its decision to meet the high-speed development in the Chinese automotive market by opening its New Energy Vehicle Technology Center in Shanghai in 2023. The region has emerged as one of the world’s leading markets for alternative drives, and MANN+HUMMEL is determined to actively shape this development.

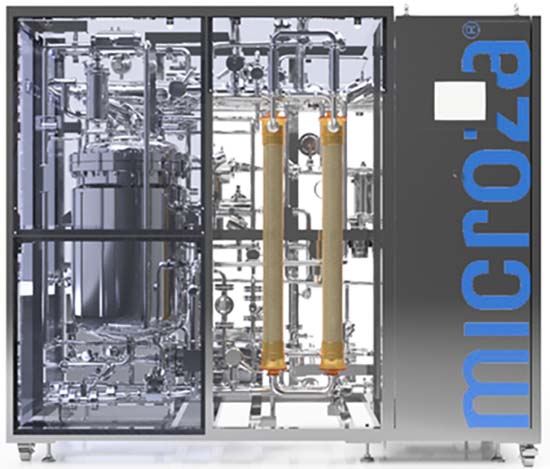

Asahi Kasei Launches Membrane System to Produce Water for Injection

In April 2024, Asahi Kasei began selling a membrane system to produce WFI (water for injection), a type of sterile water that is used for the preparation of injections. The membrane system was developed as an alternative to the conventional distillation processes for the production of WFI by leveraging system design and development capabilities of Microza™ hollow-fiber membrane for water treatment and filtration of liquid products. By reducing the need to generate steam, this system enables lower CO2 emissions and lower costs in the production of WFI.

With its Microza™ hollow-fiber membrane, Asahi Kasei has provided membrane filtration solutions in a wide range of fields including pharmaceuticals, biotechnology, food processing, environmental protection, and water treatment. Pharmaceutical water, which is used in the pharmaceutical manufacturing process, is one application in which Microza™ has gained a strong reputation among customers for its high filtration performance and outstanding technical support.

The WFI membrane system is based on steam-sterilizable ultrafiltration (UF) membranes for water treatment that have been widely used in the pharmaceutical industry. Being designed by the membrane manufacturer, the system features a compact form and excellent operability. It offers various advantages compared to the conventional distillation processes, such as a reduced need to generate steam, resulting in lower CO2 emissions and energy costs. It also offers a simplified process with no need for cooling and condensing steam, and enables higher water quality to be obtained. Previously published research with the same membranes (Steam Sterilizable UF Module & SystemOpen new window) indicates an endotoxin removal rate of >99.999% compared to 99.9% with distillation.

By facilitating a transition from the traditional distillation processes to the membrane filtration processes, Asahi Kasei expects that the new system will allow its customers to reduce CO2 emissions while producing a stable supply of safer WFI for the pharmaceutical industry.

Veolia Water Technologies Signs Agreement to Expand Presence in Wuxi, China

Veolia, through its subsidiary, Veolia Water Technologies & Solutions has signed an agreement to significantly expand its operations in Wuxi, China and partner with the Administrative Committee of Wuxi National High-Tech Industrial Development Zone (WND) to accomplish mutually beneficial objectives.

WND is among the top five national high-tech industrial development zones in China and home to 1,600 foreign-invested enterprises. Veolia has held a presence in Wuxi since 2003.

Under the agreement, Veolia plans to expand its current production capacity in Wuxi and introduce new products to build energy-saving and environmentally friendly clean production lines. The company will transform its Wuxi site into a base of R&D and product assembly in China. The expansion is part of Veolia’s newly launched GreenUp* program aimed at accelerating the deployment of solutions that decarbonize, depollute, and regenerate resources. To achieve this new strategy program, the Group relies on the combination of its core businesses with growth boosters such as Water Technologies and new solutions to preserve water resources and treat new pollutants.

Ahlstrom Adds new Line in Brazil to Support Filtration Customers

Ahlstrom, in its ongoing dedication to addressing the global need for clean air and water, has successfully completed a EUR 2 million investment for a new laminator at its Louveira plant in Brazil. This investment not only reinforces Ahlstrom’s 50-year commitment to the global filtration industry but also marks a significant expansion of its product offerings in the South American market for industrial air, industrial liquid, and fuel filtration, including products currently produced in European and North American markets.

“The new laminator increases our manufacturing capabilities and brings needed flexibility to supply our local customers with the best-in-class filtration solutions,” said Andre Pereira, Head of Sales, Filtration, Latin America. “Efficient supply chain management prevents interruptions to the supply stream, and shorter transport distances reduce carbon emissions and lower environmental impact,” he continues.

Combining filtration materials by lamination offers several advantages: enhanced efficiency, extended service intervals, and reduced energy consumption of filtration units. Laminated fuel filtration materials adapted for EURO 5 and EURO 6 standards optimize fuel consumption and reduce the emissions of harmful pollutants. In industrial filtration applications, multilayer materials support the trend for higher filtration performances and the ability to purify air and liquids to protect people and the environment.

Water Systems Warn Americans of Major Rate Fikes to Filter out PFAS

In exchange for cleaner water, Americans around the nation may soon have to pay hefty prices, writes The Hill.

Water systems are starting to warn residents of massive rate hikes as they prepare to install technology to filter out toxic chemicals in a family known as PFAS.

Utilities from South Florida to upstate New York have warned customers that they could see significant price increases after the Environmental Protection Agency (EPA) mandated that they remove the substances, which have been linked to a number of cancers and other diseases, from their systems.

Last month, the EPA said it will require utilities whose water systems contain high levels of six types of PFAS to remove them from the water.

PFAS, which stands for per- and polyfluoroalkyl substances, are a group of thousands of chemicals that have been used to make a variety of nonstick and waterproof products and firefighting foam.

The substances have also become ubiquitous in the environment, due in part to the fact that they tend to persist for a long time instead of breaking down.

Exposure to these so-called forever chemicals has been linked to increased risks certain cancers, weakened immune systems, high cholesterol, and developmental issues in children.

Adsorbi Launches Cellulose-Based Air Purification Material for the Art Industry

Adsorbi AB, a research-based startup originating from Chalmers University of Technology in Sweden, announced the launch of its first commercial product: a cellulose-based material that protects artwork and sensitive objects from degradation by air pollutants. The adsorbing material combines a long product lifetime with high security, making it ideal for museums and archives.

Currently, air pollution in museums is either ignored or the adsorbent activated carbon is used. The problem with using carbon in this environment is its short product lifetime and the risk of staining objects in collections.

Adsorbi’s material is a bio-based and high-performing adsorbent. The cellulose originates from Nordic forests and the production is in Europe. The material is used to purify air in the storage and transportation of artwork, surpassing activated carbon in terms of durability and adsorption capacity. Other important features include the material’s color indicator: the white material changes color when it needs to be replaced, enabling optimized air purification.

Schiphol Tests Innovative Device to Filter Air on the Apron

Schiphol Airport in Amsterdam is working to improve the air quality around the airport by installing an innovative air filtration system on the apron. The apron of an airport is perhaps the noisiest and most polluted place to work. The airport authority is working to change this through a pilot study using an air filtration system to reduce ultrafine particles on the airport’s apron.

The innovative air filtration system will be installed next to Pier D and is one of the ways in which the airport is working to improve the working conditions for their airport workers.

The air filtration device has been developed by Van Wees Innovations and creates airflows that ensure ultrafine particles clump together to form larger particles that can then be filtered. During this pilot on the apron, the airport will be investigating whether this machine also works indoors.

Last year, Schiphol conducted a successful pilot with this device at a fire station next to the runways. The device cleaned the air almost fully. However, because the building is in use 24 hours a day, with windows and doors being opened, the reduction during the trial came to an average of 75%.

Asahi Kasei Medical Completes Plant for Planova™ Virus Removal Filters

Asahi Kasei Medical has completed the construction of its third assembly plant for Planova™ virus removal filters in Nobeoka, Miyazaki, Japan, and held its completion ceremony on May 24, 2024.

The bioprocess business of Asahi Kasei Medical comprises Planova™ virus removal filters and equipment used in the manufacturing process of biotherapeutic products such as biopharmaceuticals and plasma derivatives, biosafety testing services, and biopharmaceutical CDMO operations. It is one of the Asahi Kasei Group’s businesses to drive future growth.

Planova™ cellulose hollow-fiber membrane filters, developed specifically for removing viruses from biotherapeutic products, were launched in 1989, followed by Planova™ BioEX hydrophilic PVDF hollow-fiber membrane filters in 2009. Both product lines have earned wide recognition among pharmaceutical manufacturers for their outstanding contribution to the safety of biopharmaceuticals, and their adoption has expanded worldwide. A next-generation line of cellulose hollow-fiber membrane filters, Planova™ S20N, was launched in 2022 featuring robust virus removal capability and simplified operation and has been highly regarded among customers.

NX Filtration to Provide Hollow Fiber NF Membranes for Mexican Water Project

NX Filtration, a global leader in advanced hollow fiber membrane technology, announced that it will supply its hollow fiber nanofiltration membrane modules to an indirect potable water reuse system in Mexico, marking NX Filtration’s largest project to date. The project was awarded by SAPAL (Sistema de Agua Potable y Alcantarillado de Leon), the Mexican water utility, and will be delivered through EcoAzur, distributor of NX Filtration’s products in Mexico.

The project, part of SAPAL’s ERA (Estaciones Regeneradoras de Agua, or Water Regeneration Stations) program aims for the production of drinking water based on water from the Desbaste wastewater treatment plant, in an indirect potable reuse (IPR) scheme including hollow fiber nanofiltration (HFNF) and advanced oxidation technologies. This water reuse concept is an important step to address water scarcity issues in the region. The project will be executed in 2 phases with a capacity of 17 million liters per day (MLD) each, with the awarded contract covering phase 1.

This marks another repeat project for NX Filtration, as SAPAL already successfully operates a smaller wastewater recovery project based on NX Filtration’s technology since 2022.

The application of NX Filtration’s hollow-fiber nanofiltration membranes will ensure efficient and cost-effective, and largely chemical free, water treatment contributing to enhanced water quality and environmental sustainability at the world’s largest scale today.

DuPont to Split Into Three Companies

DuPont recently announced plans to split into three separate publicly traded companies, a process which will take up to two years.

Under the plan, DuPont will spin off its Water and Electronics businesses, with New DuPont continuing as a diversified industrial company. Dupont said as independent entities, both Water and Electronics will benefit from increased focus and agility in their respective industries.

Water will be comprised of DuPont’s current Water Solutions line of business which last year generated net sales of approximately $1.5 billion. The portfolio of water filtration and purification solutions includes reverse osmosis, ion exchange and ultrafiltration across a variety of market segments including industrial water and energy, life sciences and specialties, municipal and desalination, and residential and commercial.

Electronics will be a global provider of electronics materials including semiconductor solutions and advanced electronics products and will include the existing Semiconductor Technologies and Interconnect Solutions lines of business, as well as the electronics-related product lines from Industrial Solutions.

New DuPont will be comprised of the existing businesses within the Water & Protection segment (excluding Water Solutions), the majority of businesses within Industrial Solutions (including healthcare), and the retained businesses reported in Corporate (including adhesives).