In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: November 26, 2024

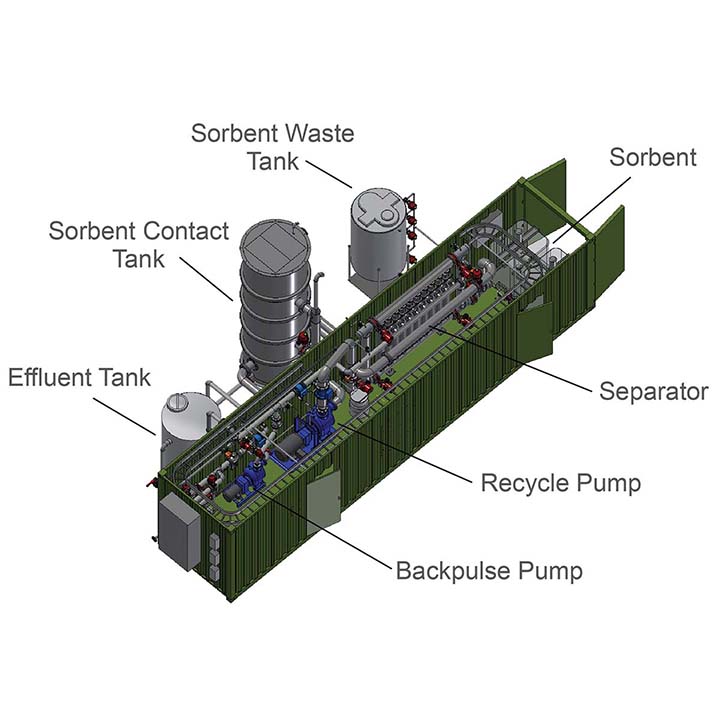

Aqua-Aerobic Systems, Inc. Introduces PFAS Removal System

Aqua-Aerobic Systems, Inc. introduced the first in their line of PFAS Solutions, the AquaPRS™ PFAS Removal System. This system utilizes a unique sorbent suspension to adsorb pre- and polyfluoroalkyl substances (PFAS) and a robust separator to produce clean water from the suspension. The suspended adsorbent slurry prevents biofouling and controls solids and mineral buildup. Additionally, the adsorbent material is specially engineered to adsorb much more PFAS (ug of PFAS/g of sorbent) than can be adsorbed by the same amount of GAC, ion-exchange resins, or other adsorbents, resulting in significantly less operating life cycle costs and net present value.

Some of its features and advantages include:

- Extremely high sorbent adsorption rates of PFAS compared to other sorbents

- Fouling and scaling controlled by slurred adsorbent

- Waste volumes are substantially lower when compared to GAC or IX Resin

- Enhanced removal of short-chain PFAS in a single process

- Process is completely automated, including adsorbent replacement

The process is completely automated, including replacement of the adsorbent. The removal process allows parameter adjustments in response to varying influent concentrations of PFAS, if necessary. Single stage operation removes PFAS/PFOA and other regulated PFAS contaminants to levels below EPA standards with low to moderate influent levels.

For very high PFAS concentrations (1,000+ ng/L of PFAS) or difficult influent water characteristics, a two-stage configuration / operation can achieve effluent levels to meet EPA effluent standards.

Atmus Filtration Technologies Boosts Global Engineering and Testing Capabilities in India

Atmus Filtration Technologies Inc., a global leader in filtration and media solutions, announced the inauguration of its Pune Technical Center in India. This state-of-the-art facility reinforces Atmus’ focus on advancing filtration technology across the commercial vehicle sector around the globe.

“We are proud to demonstrate our commitment to provide world-class filtration solutions from India with the inauguration of the Pune Technical Center,” said Avani Shah, Atmus India Global Capability Center Leader. “By building upon our existing capabilities, we are able to better serve our customers when and where they need us. The Pune Technical Center further enhances the innovation and engineering excellence that define Atmus on a global scale.”

The Pune Technical Center includes a highly equipped laboratory to test and validate filtration products and prototypes, ensuring they meet the stringent performance standards of ISO and SAE bodies. The Center provides a comprehensive suite of advanced testing, including:

- Evaluating performance conditions, for both thermally elevated and sub-zero environments

- Dust retention, water retention and life-cycle performance evaluations

- Multipass Test (ISO 4548-12 & ISO-19438)

- Singlepass Test (SAE J1985)

- Filter Capacity Test (SAE J905)

- Water Removal Efficiency Test (SAE J1488)

- Air Filter Efficiency & Capacity Test (ISO 5011), and others.

The Pune Technical Center is fully licensed by the Directorate of Industrial Safety and Health (DISH). It has been designed with safety as a top priority, adhering to stringent safety policies and guidelines. The Center is staffed by a team of highly skilled professionals dedicated to ensuring the highest standards of operational excellence.

Atmus Filtration Technologies also has a strategic joint venture with Fleetguard Filters Private Limited (FFPL), headquartered in Pune. Established in 1987, FFPL is a leading provider of world-class filtration solutions for on- and off-highway applications catering to diverse markets and customers across India.

Porex Welcomes President Janel Wittmayer

Filtration Group, one of the world’s leading filtration and separation science companies, announced the appointment of Janel Wittmayer as President of Porex. With a deep life science and medical device background that spans both startups and established global companies, Wittmayer is a seasoned leader who will accelerate Porex’s growth and thrive in Filtration Group’s mission-driven culture.

Wittmayer joins Porex from Colder Products Company (CPC), a Dover company, where she served as President. She brings decades of experience in the life science industry to the role, and will help build scale at Porex through a highly commercial mindset and customer-centric approach.

“Janel is a dynamic and growth-oriented leader,” said Jon Pratt, President & CEO of Filtration Group. “Porex is a phenomenal business, and Janel’s passionate approach to commercial growth and extensive experience in custom products and solutions across broad markets make her an ideal leader to strengthen Porex’s position as an industry leader.”

As Porex President, Wittmayer will join the Filtration Group Executive Leadership Team and will focus on furthering Porex’s growth trajectory and advancing the company’s strategic objectives in custom products.

“The opportunities ahead of us at Porex are truly exciting,” said Wittmayer. “I look forward to partnering with this team of world-class entrepreneurs and innovators to grow the business and bring our customer’s ideas to life.”

Prior to CPC, Wittmayer held positions at Nordson Medical, Tactile Medical, and Medtronic. She holds a BSc in Chemistry and an MBA from the University of Minnesota.

Smith & Loveless Inc. Introduces TITAN MEM-BOX™

Smith & Loveless, a leader in factory-built Membrane BioReactors (MBRs), recently introduced its latest factory-built membrane system innovation, TITAN MEM-BOX™, a packaged membrane process zone that transforms activated processes into fully functional MBRs.

The integration of TITAN MEM-BOX™ into a treatment process scheme elevates conventional wastewater treatment plants to cutting-edge water resource recovery facilities (WRRFs) by (a) improving plant capacity (b) improving effluent quality (c) implementing water reuse to counter water scarcity and (d) meeting population growth and tightening permit demands.

Designed for both existing and newly proposed plants, the TITAN MEM-BOX™ membrane system

eliminates the need for constructing additional treatment basins while streamlining the design process.

This approach drastically reduces project time and costs associated with concrete tank construction. The

factory-built and tested system arrives to the plant site ready to be integrated into the treatment scheme to produce superior effluent and achieve biological nutrient removal.

The TITAN MEM-BOX™ comes with integral hollow-fiber or flat-sheet membranes (depending upon the

application). With S&L’s intuitive QUICKSMART™ PLC controls and plant automation, which includes

automatic membrane cleaning, TITAN MEM-BOX™ is designed to make operation and maintenance the

easiest of any membrane system.

The TITAN MEM-BOX™ also integrates with S&L’s large-flow Model R OXIGEST® treatment system

to form the OXIGEST MBR™, offering a complete MBR treatment solution for flows of 250,000 gpd and

larger, up to 2+ MGD per train.

Smith & Loveless’ experienced technical staff assists project designers and end-users through every step

of the project, from the pre-design phase to field installation and beyond with complete and reliable

lifetime after market support as proven during S&L’s 75-plus years.

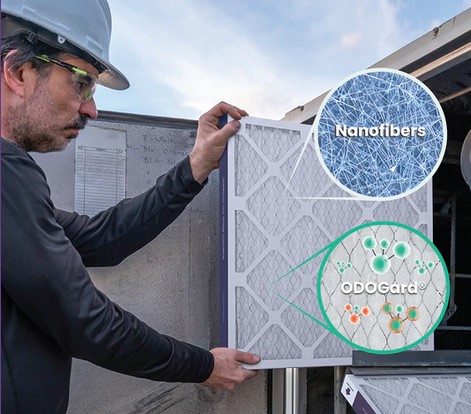

Greentech Environmental Unveils MERV 8A High-Capacity Filters with ODOGard® Technology

Greentech Environmental, a leader in air filtration, announced its newest innovation: the MERV 8A High-Capacity Filter with embedded ODOGard® technology. Engineered to meet the air quality needs of various sectors, including hospitality, multi-family, residential spaces, education, commercial buildings, and assisted living, this filter represents a breakthrough in HVAC filtration technology.

The MERV 8A filter offers dual benefits: advanced filtration and superior odor control through Greentech’s licensed ODOGard® technology. ODOGard® is a revolutionary odor control solution that neutralizes unpleasant odors at the molecular level. Unlike traditional odor-masking products, ODOGard® bonds with odor molecules, rendering them undetectable to the human nose. “At Greentech, we listen to our customer’s needs, and our MERV 8A filter with ODOGard® technology was engineered for clients who need better IAQ and odor control at an affordable cost,” said Blake Bobosky, VP of Sales and Marketing. “It’s a game-changer for hospitality and other sectors where first impressions matter, offering an effective, cost-conscious alternative to expensive impregnated carbon filters.”

Key Benefits of MERV 8A Filters with ODOGard® Technology:

- Superior Odor Elimination: This filter eliminates common VOCs and odors at the molecular level, unlike standard filters that merely trap particles.

- Cost-Effective Solution: Up to 50% less expensive and 99% more effective in odor reduction compared to impregnated carbon filters.

- Reliable Filtration: True Mechanical High-Capacity filter maintains its MERV 8A rating over time, ensuring consistent performance.

- Premium Build Quality: Fully sealed design prevents air bypass for maximum filtration efficiency.

- Made in the USA: Manufactured to high standards, ideal for commercial applications in hospitality, multi-family housing, and commercial buildings.

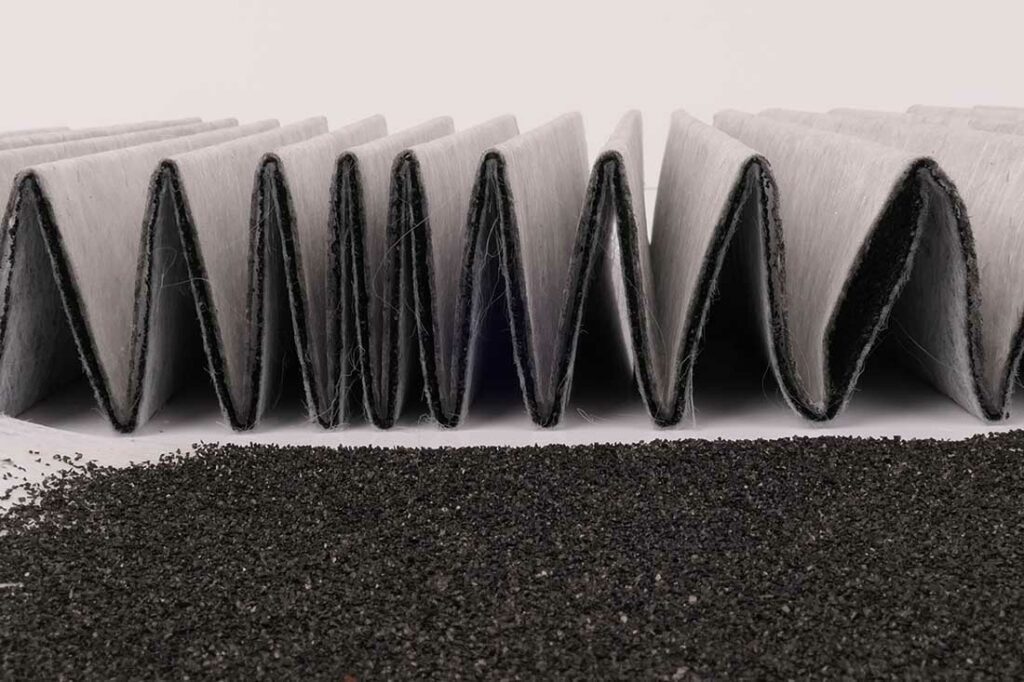

Jowat Develops Powerful Hot Melt Adhesive with Hazard-Free Labeling

Jowat SE recently unveiled the new Jowatherm® PUR MR 614.70, an innovative hot melt adhesive that provides highest performance without hazard pictograms.

Jowatherm® PUR MR 614.70 has been specially developed for the production of filters to purify the air inside of vehicles and buildings. The adhesive efficiently connects several layers of different filter materials while maintaining the maximum possible surface area of the activated carbon for an optimum filtration.

The long open time of Jowatherm® PUR MR 614.70 facilitates outstanding results in the lamination process of activated carbon and composite filter media. Other advantages of Jowatherm® PUR MR 614.70 are the product’s neutral odor and its very low fogging and emission values. The adhesive can be processed with widely established machine configurations and delivers impressive results with low application amounts.

A special highlight of Jowatherm® PUR MR 614.70 is the hazard-free labeling, which contributes to safe and healthy workplaces. Due to a processing temperature about 40°C lower compared with other PUR hot melts, the adhesive also saves resources and is more environmentally friendly.

Toray Releases Reverse Osmosis Membrane Elements that Double Impurity Removal to Produce Ultrapure Water from Recycled Wastewater

Toray Industries, Inc., announced that it began advance sales to domestic water treatment engineering companies of the TBW-XHR series of reverse osmosis (RO) membrane elements. These neutral molecular high-removal, low-pressure elements double urea removal efficiency when using recycled wastewater in producing ultrapure water suitable for such fields as semiconductor manufacturing.

Increasingly severe global water shortages have prompted semiconductor manufacturers to consider using recycled wastewater and seawater as sources for ultrapure water for manufacturing semiconductors, augmenting efforts to increase wastewater reuse at foundries, which consume huge volumes of ultrapure water.

Production of Ultrapure water from these water sources requires advanced technology capable of removing salts, silica, boron, urea, alcohols, and other impurities. Urea poses a particular challenge, as it impacts both the safety of drinking water and in the quality of ultrapure water used in photolithography processes for semiconductor manufacturing. Highly efficient urea removal is crucial to meet stringent demands of this application. The urea concentration in conventional recycled wastewater is about 30 micrograms per liter, or around three times higher than in tap water.

By innovating the RO membrane manufacturing process, Toray developed a new membrane structure control technology that allows selective water permeation and enhances the removal of urea, boron, alcohol, and other substances. These efforts culminated in the TBW-XHR series of RO membrane elements, whose urea removal efficiency is double that of conventional systems, achieving high water permeability at low pressure.

The company employed advanced analytical technology from Toray Research Center, Inc., in developing this product. Internal evaluations found that urea removal efficiency is nearly 90%, contributing to a stable supply of high-quality ultrapure water needed by advanced semiconductor fabs. The technology reduces urea levels by half compared with conventional methods, supporting ultrapure water production from recycled wastewater.

Pall Wins Prestigious Global Aerospace Supplier Award from Rolls Royce

Pall Corporation, a leader in filtration, separation and purification technologies, has been awarded the 2024 Global Aerospace Supplier of the Year by the Aerospace Procurement function within Rolls-Royce. This award is given annually, to an Aerospace Procurement supplier that demonstrates world-class performance and partnership. Pall was recognized as the 2024 leader across the entire Rolls Royce aerospace supply chain.

“It is an honor to be recognized as the Global Aerospace Supplier of the Year by Rolls Royce, a true leader in the aerospace industry,” said Karmyn Norwood, Vice President and General Manager of Pall’s aerospace business. “This recognition reflects our team’s unwavering commitment to delivering a world-class experience to our customers and underscores our dedication to excellence.”

The award ceremony was held at the Bristol Aerospace Centre, home to the iconic Concorde, and celebrated the very best in aerospace supply chain performance with more than 300 representatives from 148 global suppliers and partners across the Rolls Royce supply chain.

Pall has been a distinguished member of the Rolls Royce High Performer Supplier Group for the past five years, consistently achieving a minimum average score of 90% across 4 critical categories: management, delivery, quality and cost.

Metso Launches a Renewed Metso Plus Concept

In 2021, Metso launched its Planet Positive approach as a concrete answer to tackling the sustainability challenges of its customer industries. Ever since, the products and services included in Metso’s sustainable portfolio have been important to differentiate the company. To date, Metso has over 100 products in its portfolio of sustainable products. These products are demonstrably more energy or water efficient than the industry benchmark or Metso’s previous generation products. They provide added benefits to the customers, helping them cut their CO2 emissions, reduce pollution to land, air and soil, increase circularity and safety, and improve productivity.

To comply with the proposed changing EU legislation and to emphasize our focus on supporting our customers with their key challenges, Metso is renaming its Planet Positive offering to Metso Plus. Similarly, the former Planet Positive label will change and have a new design.

“Our focus is on driving the development of more sustainable solutions together with our customers. We believe that we can enable the biggest positive change by supporting them in their sustainability ambitions while driving the industry towards more sustainable practices,” says Marius Verwoerd, head of Metso’s Sustainability.

Silhorko-Eurowater is Rebranded as Grundfos

Grundfos announces the rebranding of Silhorko-Eurowater, officially becoming Grundfos. Silhorko-Eurowater was acquired by Grundfos in 2020, as part of Grundfos’ strategy to strengthen its position in the water treatment market. Today’s rebranding marks the next step in the integration journey.

“By combining our capabilities in Grundfos Water Treatment Europe, we can offer even better solutions to customers with enhanced know-how and a broader range of products and services, with the same focus on quality and customer service that our companies are known for today,” said Francesco Magri, head of the European water treatment business in Grundfos.

Since Silhorko-Eurowater was founded 90 years ago, it has become a leading player in water treatment across Europe. Today, the company’s solutions ensure water treatment for a wide variety of purposes from industrial processes to clean drinking water and food production, and even for the extremely high-demanding Power-to-X plants. Internationally, the company was previously known as Eurowater, while in Denmark, where it is headquartered, it was known as Silhorko.

The now former Silhorko-Eurowater becomes part of the newly established business area Grundfos Water Treatment Europe, which also includes Grundfos’ recent acquisition of Culligan’s Commercial & Industrial business in Italy, France, and the UK. The new business area has a total turnover of 200 million euros and employs 1,000 water treatment specialists, positioning Grundfos as a leader in water treatment in Europe.

Veolia Water Technologies Launches New Mobile Water Services

Veolia Water Technologies has launched its mobile water services offering to the pharmaceutical, cosmetics and life science industries across Europe. This initiative provides a comprehensive range of technologies and services bundled as a rental service to deliver reliable, uninterrupted and sustainable solutions for manufacturing, cleaning, and complex liquid waste treatment for compliant offsite management.

For purified water (PW) and cold water for injection (WFI), Veolia deploys OrionTM and IonproTM multi-technology units while the PolarisTM is available for apyrogenic pure steam. These units deliver water and pure steam for a variety of applications which are compliant with both European and US Pharmacopeia as well as FDA, cGMP and GAMP requirements.

For complex waste streams containing solvents and active pharmaceutical ingredients (APIs), EvaledTM evaporation and MPPTM liquid-to-liquid extraction technologies can recover valuable resources and reduce offsite waste disposal, minimizing environmental impact of these waste streams in a cost-effective way.

The units can be operated independently or together. This service is available for both short-term (weeks to months) or as a longer-term permanent solution (several years) as an alternative or to complement a fixed plant.

www.veoliawatertechnologies.com

Toray Supplies Membranes to Indonesia Strategic Project

Toray Industries, Inc., announced that it has supplied reverse osmosis (RO) and ultrafiltration (UF) membranes to the Refinery Development Master Plan (RDMP) Balikpapan Project in Indonesia. This is one of the largest initiatives for PT Pertamina (Persero), the nation’s premier oil refiner. That project aims to lift daily capacity at one of that company’s refineries to 360,000 Barrels while reducing import volumes.

Indonesia is pushing forward with strategic initiatives to develop new cities and industries. A seawater desalination plant at Pertamina’s oil refinery in Balikpapan, East Kalimantan, will be able to produce 84,000 cubic meters daily of boiler and drinking water after it begins operating later this year.

Toray recently supplied a package of RO elements and new rack-integrated UF modules. It will leverage this achievement in collaborating with regional liaison subsidiary Toray Asia Pte. Ltd. in Singapore to keep supporting progress in Indonesia and across Southeast Asia.

Toray secured this order largely on the strength of comprehensive technical services leveraging its advanced RO and UF membrane technologies. Another factor was its solid reputation worldwide in RO membranes over the past two decades, particularly in seawater desalination. The diverse features of the company’s rack-integrated UF module also attracted Pertamina.

Toray has expanded sales, production, and technical support for RO and UF membranes over the years to help resolve global water shortages. Applications range from seawater desalination and wastewater reclamation to industrial usage. As of March 31, 2024, its RO and UF membranes delivered a cumulative 136,000,000 and 11,900,000 cubic meters, respectively, of fresh water every day.

Morocco and Veolia Join Forces for the Seawater Desalination Project

Morocco has signed a MOA with Veolia for the establishment of a strategic partnership to develop on a seawater desalination project that will be the largest in Africa and the second largest in the world. It will supply drinking water to regions of the Kingdom particularly affected by drought.

Located near Rabat on the Atlantic coast, the project will be structured as a public-private partnership, involving the construction, financing and operation for 35 years, by Veolia, of a seawater desalination plant. With a capacity of 822,000 m3 of drinking water per day, or 300 million m3 per year, it will ensure the supply of the Rabat-Salé-Kénitra and Fès-Meknès regions to meet the water needs of nearly 9.3 million inhabitants.

This initiative is part of the Moroccan national energy strategy, launched by King Mohammed VI, which aims to strengthen water supply security and to face the challenges of climate change.

As a global leader in water technologies, Veolia will bring the best of its cutting-edge expertise in desalination for a reference plant in terms of efficiency, innovation and environmental protection. Its operational expertise will also ensure high plant performance by balancing investment and operating costs, thus ensuring the most competitive water price over the entire life cycle of the facility. The facility could be powered by low-carbon electricity, mainly from renewable sources.

Gessner Launches MecNa Air Filter Media

Gessner has introduced MecNa, revolutionary air filter media which addresses the common issue of reduced lifespan due to low dust holding capacity in current nanofiber filter media. Developed in the post-COVID pandemic era, when guaranteed efficiency for critical filtration applications became essential, MecNa™ sets a new standard by offering unparalleled longevity and filtration performance.

The uniqueness of MecNa™ is its revolutionary 3D nanofiberstructured media design. Unlike continuous electrospun fibers MecNa™ embeds individual nanofibers within the filter media, enhancing both durability and performance.

This particular construction overcomes the typical limitation of reduced lifespan of filter elements due to low dust holding capacity, ensuring high initial resistance to airflow. Additionally, since it relies on mechanical filtration, you can count on consistent efficiency without any particle removal efficiency dropping problems commonly seen in electrostatic filter media.

Ahlstrom Joins the World Business Council for Sustainable Development

Ahlstrom, a global leader in fiber-based specialty materials, has joined the World Business Council for Sustainable Development (WBCSD), a global organization committed to accelerating the transition to a sustainable world.

By becoming a member of WBCSD, Ahlstrom will collaborate with some of the world’s most forward-thinking companies to further the global sustainability agenda. Together, Ahlstrom and WBCSD aim to tackle urgent environmental issues, including climate change, the need for clean air and water, decarbonization, biodiversity loss, and plastic pollution.

“At Ahlstrom, we are committed to being part of the solution to global sustainability challenges. We believe that sustainability is a complex journey that requires collaboration to drive meaningful change. Our purpose, ‘Purify and Protect with Every Fiber for a Sustainable World,’ guides our efforts to innovate fiber-based solutions that are safe and sustainable by design,” said Helen Mets, President & CEO of Ahlstrom.

GESSNER Introduces Filter Media with Eco-Friendly Lignin

GESSNER’s lignin filter media is designed to reduce your product carbon footprint. Unlike traditional filter media, GESSNER’s cellulose filter media is saturated with an eco-friendly lignin-based resin, ensuring that your filter element offers best performance, while taking a step into more sustainable filtration solutions.

Lignin is a natural polymer found in the cell walls of plants, providing structural support and rigidity. In our filter media we use lignin for its sustainable properties, offering an ecofriendly alternative to replace fossil-based resins.

By adding the eco-friendly lignin saturation, GESSNER developed a more sustainable product that does not compromise on filtration performance nor on its mechanical properties. Additionally, it decreases formaldehyde emissions during the curing process.

Compared to standard media with a fossil-based resin saturation initial calculations show that the new lignin-based saturation filter media offers an improved product carbon footprint.

The lignin-based resin saturation is used in various automotive applications, including engine air intake, oil, and fuel filtration. But the application of lignin is not limited to these – any cellulose filter media which is currently using phenolic resins can seamlessly transition to the lignin modified saturation.

Donaldson Announces Official Partnership with the 2026 Special Olympics USA Games

Donaldson Company, Inc., a leading worldwide provider of innovative filtration products and solutions, announced that it has committed to be a partner of the 2026 Special Olympics USA Games set to take place in June 2026 in Minneapolis, Minnesota.

“At Donaldson, we strive to positively impact the communities in which we live and work,” said Tod Carpenter, chairman, president and chief executive officer. “Partnering with the 2026 Special Olympics USA Games is a natural extension of this and underscores our long-held belief that inclusion is essential in our communities and throughout the world. Together, we aim to inspire and empower athletes of all abilities, demonstrating the power of unity and creating opportunities for everyone.”

The company joins a growing list of passionate partners for the 2026 Special Olympics USA Games. As a proud partner, Donaldson and its employees will actively participate in key Games events and initiatives. The company plans to host Special Olympic athletes on their Bloomington campus, as well as provide numerous volunteer opportunities for employees.

Memsift Innovations Acquires Graphene Membrane Technology Ngee Ann Polytechnic

Memsift Innovations, based in Singapore, has entered into a technology transfer agreement with Ngee Ann Polytechnic, also in Singapore on an innovative graphene membrane technology.

The technology, featuring graphene oxide-based hollow fiber ultrafiltration and nanofiltration membranes, was developed based on over a decade of research and development. The ultrafiltration technology utilizes a graphene oxide-block copolymer composite renowned for its exceptional chemical and thermal stability, making it ideal for harsh industrial applications. Its unique surface chemistry forms a protective water layer that effectively prevents fouling. The nanofiltration technology employs a robust single-layer modified graphene oxide membrane with synthetic water channels, enhancing selectivity and permeability. This enables efficient molecular-level separation and differentiation between monovalent and multivalent ions.

FLSmidth and Enter Engineering Sign Strategic Agreement

FLSmidth and Enter Engineering have signed a strategic cooperation agreement covering the development of new production lines at Almalyk Mining and Metallurgical Complex’s MOF-4 copper processing plant in Uzbekistan. The agreement includes the supply of core processing equipment and design services with an estimated total value of $215 million.

Enter Engineering’s construction work on the MOF-4 plant is already underway, and when completed, it will enable Almalyk Mining and Metallurgical Complex to become one of the world’s largest copper, gold, and molybdenum producers.

Under the terms of the agreement, FLSmidth will supply Enter Engineering with a range of core process equipment including High-Pressure Grinding Rolls (HPGRs), Vertical Mills, Screens, Thickeners, Dewatering Filters, Gravity Concentrators and Hydrocyclones.

Sami Takaluoma Appointed President and CEO of Metso Corporation

Metso’s Board of Directors has appointed Sami Takaluoma (born 1973, M.Sc. (Eng.)) as Metso’s new President and CEO. He assumed his duties November 1, 2024. Metso’s current President and CEO, Pekka Vauramo, will continue with the company as per his contract until the end of 2024, ensuring a smooth transition of responsibilities. Sami Takaluoma has been with Metso since 1997 and has led Metso’s Services business area since 2021. He has been a member of Metso’s Leadership Team since 2017.