By Dan Morosky, Rosedale Products, Inc.

May/June 2014 | Volume 33, No. 3

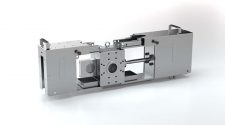

The centrifugal-action separator can remove grit, sand, metal chips, fines, and other solids from liquids. It is perfect for use as a pre-filter to extend the life of fine filtration systems. These units require little or no maintenance, as there are no moving parts to wear out, or filter media to replace. The unit only requires a simple purging, eliminatingdowntime. It handles flows from 6 gpm and retention ratings to 50 micron.

|

Typical Applications |

Features | Options |

| ÔÇó Process water | ÔÇó Low constant pressure drops | ÔÇó Different outlet connections |

| ÔÇó Well water | ÔÇó Piped housings | ÔÇó Special materials |

| ÔÇó Steel mills | ÔÇó Carbon steel or stainless steel (304 or 316) construction for housings |

|

| ÔÇó Protection of spray nozzles and other small orifices |

ÔÇó All housings are electro-polished to resist adhesion of dirt and scale |

|

| ÔÇó Paint spray booths | ÔÇó ASME code stamp available | |

| ÔÇó Industrial laundries | ÔÇó Pipe sizes 3/8 through 10-inch (larger sizes also available) |

|

| ÔÇó Pump protection | ||

| ÔÇó Sprinkler systems | ||

| ÔÇó Food processing | ||

| ÔÇó Chemical processing | ||

| ÔÇó Pulp & paper mills | ||

| ÔÇó Petrochemical industry | ||

| ÔÇó Chip removal from cutting coolants |

||

| ÔÇó Heat exchangers | ||

| ÔÇó Solids recovery | ||

| ÔÇó Domestic water | ||

| ÔÇó Quench water | ||

| ÔÇó Mining operations | ||

| ÔÇó Power plants | ||

| ÔÇó Car and vehicle wash systems | ||

| ÔÇó Spray nozzle protection | ||

| ÔÇó Parts washing systems | ||

| ÔÇó Recirculating cooling water | ||

| ÔÇó Pre-filter for seawater |

INSTALLATION

The Separator should be installed in a near vertical position. The unit should be supported by means other than the inlet/outlet piping. First, connect the outlet of the unit to the outlet piping. Then install any supports, such as U-bolts or legs.

Next, connect the inlet piping to the inlet. Test for leaks and separation. The unit is now ready for operation.

PURGING AND MAINTENANCE

Separators must be purged regularly. If they are not, the separated solids will accumulate and overflow the collection area, affecting performance and contaminating effluent.

Users can manually, automatically, or continuously purge the collection area of the separator. Manual purging requires that the operator open a simple valve and empty the contents. Automatic purging can be done many different ways, but the simplest is setting a timer to open and close the valve, purging the contaminant on a regular basis. Continuous purging simply requires leaving a manual valve partially open at all time, letting the contaminant leak out at a controlled rate.

For best results, all purging should be done while the separator is in operation. Avoid purging “uphill,” which will result in buildup and clogging, affecting performance and operation.

Simple rules of maintenance include checking the purge valve regularly for clogging, scale, and buildup. If the unit is installed in an area where the ambient temperature is below freezing, the collection area and all purge piping should be kept from freezing while operating. If left in idle state under freezing conditions, the entire unit must be drained of liquid, and the collection area must be purged of solids.

HOW IT WORKS

Fluid enters the pressure vessel tangentially at high velocity. A centrifugal action is created, which forces the solids to separate and enter the sump, while the clean liquid exits up through the standpipe. The solids collect in the sump, and can easily be purged. The operation is so simple, it can be set to automatically purge on a timed interval.

For more information contact:

Rosedale Products, Inc.

3730 W. Liberty Road | Ann Arbor, MI 48103

Tel: 800-821-5373 or 734-665-8201

Fax: 734-665-2214

Email: filters@rosedaleproducts.com

Website: www.rosedaleproducts.com