The next edition of the FiltXPO, North America’s technical conference and exhibition for the filtration and separation industry, will be presented March 29-31, 2022, in Miami Beach. The event will feature five panel sessions focused on how filtration can address today’s societal challenges related to the pandemic, environmental sustainability, climate change and other issues. As we lead up to this event, IFN is featuring roundtable Q&As with FiltXPO panelists around the topics they will be discussing at the conference. The following is Part II in the series, with a focus on sustainability in filtration, anchored by comments from Phil Whitaker, BFC Solutions (Moderator), Kevin Barry, Second Nature Brands (Panelist), and Andreas Scope, Ph.D., Mann+Hummel (Panelist). Part I in this series, “Filtration standards – friend or foe?”, can be found here.

Phil Whitaker, CEO

BFC Solutions, Moderator

Phil Whitaker is chief executive officer at BFC Solutions. A senior-level executive, he has provided the vision, strategy and transformational leadership that differentiates global companies in the marketplace and catapults revenues to new heights. Phil has worked with startups, turnarounds, and M&As to help them get to the next level by applying unconventional strategies

Kevin Barry, Co-Founder/Chief Operating Officer,

Second Nature, Panelist

Kevin Barry is the co-founder and chief operating officer for Second Nature, where he oversees operations, supply chain, software engineering, IT, and product development. Kevin played a crucial role in building Second Nature’s subscription air filter business, and since the company’s 2012 inception, he has overseen company operations.

Andreas Scope, Ph.D.,

Mann+ Hummel, Panelist

Andreas Scope, Ph.D., has more than 15 years of experience with air filtration and gas adsorption. He has managed Mann+Hummel’s cabin air filter R&D team for five years and led the company’s North Carolina Innovation Center for four years. Currently, Dr. Scope is working as director of Life Science Innovation at Mann+Hummel’s headquarters in Ludwigsburg, Germany.

Why is now a good time to consider sustainability within the filtration industry?

Phil Whitaker, BFC Solutions, Moderator: I think sustainability, environmental impact, is relevant to every industry. And I think that becomes more so every year.

We’ve seen over the last 12 months, probably the biggest explosion in demand for filtration medium, certainly in our lifetimes. One of the massively expanded applications over the past 12 months has been the single-use facemasks. And that’s really brought to people’s attention the environmental impacts of the use of large volumes of synthetic media. I read somewhere that if every American used one mask every day, that would generate over 300,000 tons of waste media, and really 300,000 tons of plastic waste, per day. So that’s an extreme example, but I think it does highlight in everybody’s mind the reverse side of industry growth and industry success is we all need to be aware of how that impacts the environment around us and how we’re going to handle the product from cradle to grave.

Kevin Barry, Second Nature Brands, Panelist: One in five consumers in the United States is making a purchase decision based on value that is being added to a product. That could be either a “green” product or a sustainable product that has some type of corporate social governance program behind it providing value to stakeholders outside of folks who are only looking to make profits for shareholders.

So that’s 20% of consumers. That’s been growing year over year. This category did not exist 20 or so years ago, when air filters, especially on the residential side, were just coming to be popular items that you would see in a retail store and would be purchasing on a regular basis.

And so, while some of the leading air filter manufacturers have over time focused on the total energy footprint of their products in terms of the energy they consume during their operation lifetime, I think there’s been less focus on the recyclability or upon the biodegradability of the components that are used in the product itself. And I think that we really haven’t taken as long and hard a look at that aspect as we should.

What I’m starting to see through our customers, through folks whom I speak with, is that not only do people in general feel badly about using a one-time-use product for a few months that gets thrown away, they are wanting to see innovation and change in the industry, which today has really not significantly changed much since the pleated air filter came out. It’s largely been a very standard product that gets used for the duration of the filter’s lifespan and then gets thrown into a dump.

Not a pretty picture when you think about how many of those filters are disposed of. And I know one air filter manufacturer who, a few years ago, was touting that they made enough air filters to circle the circumference of the Earth twice each year … just think about that. That was just one manufacturer, and all of those filters went into landfills – a very low amount of that was post-consumer recyclable.

Andreas Scope, Mann+Hummel, Panelist: Actually, I think we are in a very interesting phase in the filtration business at the moment. So, we’ve almost gotten past the COVID-19 pandemic, and I think this pandemic opened the eyes of many people, end users, customers about the importance of filtration. So I think we will continue to focus the filtration business on performance, on separation efficiency, on capacities and so on, but at the same time there will also be a big focus on energy efficiency, and low differential-pressure filters will play a big role.

And what is another interesting and important aspect for the near future is the sustainability topic because people understand the necessity for filtration and separation, but at the same time customers, not only within the industry, but also end users and operators, are starting to ask questions about how sustainable are filter elements and filter products. And I think the filtration industry needs some good, robust and reliable answers to these questions.

When we think about sustainability, or environmental footprint, there are several dynamics at play related to filtration. While filtration helps remove a lot of pollution from the environment, the energy required to operate filtration systems is an area where efficiency is key, and then there are the filtration materials and filters themselves. How do you see this dynamic of pros and cons of filtration from an environmental footprint perspective?

Kevin Barry: Sure. Well, there are three specific areas where I see filter companies, especially residential filter manufacturers, can really help out with the environment. One of which is changing out air filters on time. The U.S. Environmental Protection Agency has estimated that 5-15% of a home’s energy cost can be reduced by just changing air filters on time. So that’s a huge energy reduction – if every single household was changing their air filters on time that would be a great contribution.

The second thing that can be done is the transportation of air filters. Air filters are very large products. They take up a lot of volume. There’s a lot of dead space in them. So as they’re transported from manufacturer through various different stops before getting to the final use location, it’s using a lot of resources, adding to our carbon footprint – that is really not 100% necessary. When you start to work to lean out the filter product and get it down to just the core materials that are being used, it is certainly possible to have a more efficient footprint for an air filter.

And then lastly is the material make-up and components that are used in an air filter. Common air filter components today are plastic, metal, and paper, and many of those have the ability to be recycled, but today, there are no large-scale programs for air filtration recycling on a consumer level for a residential consumer who wants to put their air filter back into a second life, even if it’s a second life where something gets used for a few more years before it goes to a landfill. There are companies and offerings that are able to do those types of programs, but that still has not been developed in the air filtration space, and that’s a really big opportunity that I think would be extremely beneficial for the environment and for the conscientious consumers who are interested in having a green product.

Filtration is something that we are all involved in on a daily basis, and my opinion is that as stewards of the Earth, we have a fiduciary duty to do what we can to leave the world in a better place than when we came to it. If we just make a whole bunch of money and throw a whole bunch of things into the trash, I don’t really believe we’re leaving the world a better place for the next generation coming forth.

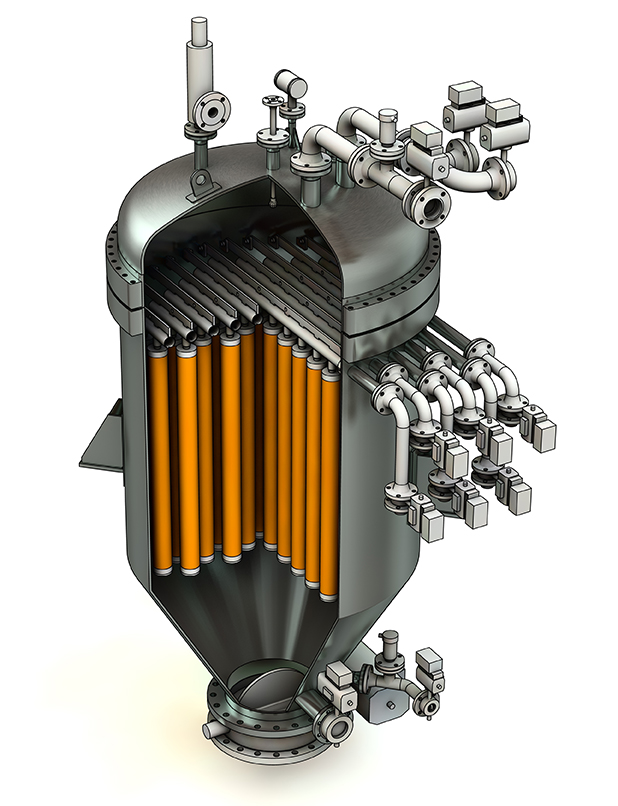

Andreas Scope: In industrial applications, there is at the moment very interesting and quick development towards better and also more sustainable filters. And today there are even some interior applications which are pretty new, and which rely on robust, efficient and sustainable filtration and separation processes.

I just want to mention the hydrogen industry where there was a big discussion about green hydrogen, gray hydrogen, blue hydrogen. And especially here in the EU the development of the hydrogen industry depends on robust and very efficient membrane separation processes. And that’s one field where there is tremendous pressure on the filtration industry to come up with energy efficient membranes in order to make hydrogen processes more sustainable. So that’s one example from industry.

My personal opinion is that the sustainability panel is one of the most exciting and most interesting panels at this conference because the future of filtration depends on the sustainability approach. There are so many challenges and so many questions raised from operators, from customers, from end users where we need to have good and reliable answers, and we have to collaborate.

So, it’s not an effort one company can tackle. If you look at the lifecycle assessment of a product, there you need a lot of input data from suppliers, from logistics. And if you extend the scope of your lifecycle assessment downstream, you must consider: How is the product used? How will the product be disposed? And to collect this input to get a solid base of input data, the entire filtration industry and the entire supply chain has to work together. And I think a panel like the one at the next FiltXPO can be a good starting point to foster the discussion and also to foster the collaboration.

I think in general compared to other industries the filtration and separation industry is in a very good position. So [Mann+Hummel] has a mission, which is “separate the useful from the harmful.” And this already demonstrates the importance of filtration for the environment. If you look at typical filtration applications, like for HVAC filters, for water filtration, in the automotive industry … filters do something good for the application and in many cases something good for the environment. The filtered fluids should be usually cleaner than the initial fluid. So that’s already some good … So this is already a very good starting point. And energy efficiency is also super important for many end users and operators because it has a direct impact on their operating costs.

Phil Whitaker: Clean air, whether it’s in an occupied space or a manufacturing space, is a desirable product – something that we are going to need more and more of as we move forward. And there has to be a balance between the delivery of the clean air necessary for our lives versus the environmental impact that that carries. And I think it’s our responsibility to minimize that impact.

An air filter is an interesting thing; in that it really has three components to its environmental impact. The first one is the product itself, and there are opportunities in the future to focus on the materials that the product is made of both in terms of the individual components, in terms of biodegradability, recyclability, disposability, and so on.

But the use of air filtration also has an impact on the consumption of the power and the total carbon footprint of a facility downstream of the actual filter by contaminating or preventing the contamination of downstream equipment. Of course, the forcing of air through an air filter also consumes energy. So, with the correct design priorities, with the right focus, we have the opportunity to reduce the environmental impact of the delivery of clean air in several different areas. And I think it’s incumbent upon us to take on that challenge. But then also to communicate how we are addressing that challenge with the informed and concerned consumer that wishes to see those topics addressed.

And so while some of the leading air filter manufacturers have over time focused on the total energy footprint of their products in terms of the energy they consume during their operation lifetime, I think there’s been less focus on the recyclability or upon the biodegradability of the components that are used in the product itself. And I think that we really haven’t taken as long and hard a look at that aspect as we should.

Another area is the transportation of air filtration products. These are large, light, bulky products, and the transportation footprint and the contamination of pollution associated with the moving of these products around the country and even internationally sometimes is also something that the industry hasn’t yet addressed.

So, in cradle-to-grave terms, considering every aspect that an air filter’s lifecycle can impact from an environmental point of view, this is something that’s relatively new to the industry. I think there’s a lot of opportunity there, but I also think it requires a lot of research, a lot of investment, and it’s something that I think not every company is willing to take on as a responsibility – but for those that are, I think there are tremendous opportunities.

What do you see as the biggest sustainability challenge the filtration industry faces?

Andreas Scope: Nowadays customers are starting to ask more about the disposal of filters, how are the filter elements produced, can we use more recycled materials, can we quantify the carbon footprint or the CO2 impact of our filters? And we are working on those topics. We try to come up with some answers to those questions, but we also realize that looking at the supply chain, there are also some challenges. If we go to a filter medium supplier, they understand the question, but in many cases, they are not able to answer those questions about carbon footprint, about lifecycle assessment, about CO2 impact. And I think that’s a big challenge and that’s something where we in the filtration business altogether, along the supply chain, have to work together. We have to collaborate and develop the good answers, which hopefully then also convince our customers and the end users.

Phil Whitaker: I think the biggest challenge is that the solution does not lie in the hands of one particular area of our industry. So if we want to focus on recyclability, biodegradability, then that is to a large extent, going to lie in the hands of the media manufacturers, because they are going to have to develop and implement that technology in a commercially competitive environment. If we then want to take those more environmentally friendly medias and deploy them in a reusable or recyclable or replaceable way, that’s going to take the involvement and the engagement of the filter manufacturers. And then even if we have a recyclable, reusable, biodegradable product, as a result of cooperation between medium manufacturers and filter manufacturers, the customers themselves are then going to have to be willing to make the shift.

So the filtration industry as a whole has a good deal of inertia when it comes to innovation in part because there’s a huge installed base of old traditional products. And moving customers from old products to new products is a slow process in the air filtration industry. So it’s going to take participation of various different parts of the economic whole to cooperate in order to achieve the goals that ultimately we want to achieve.

If you look at the lifecycle assessment of a product, there you need a lot of input data from suppliers, from logistics. And if you extend the scope of your lifecycle assessment downstream, you must consider: How is the product used? How will the product be disposed? And to collect this input to get a solid base of input data, the entire filtration industry and the entire supply chain has to work together.

That said, I think we can overcome this challenge. We put a man on the moon. We can come up with a recyclable air filter, I’m sure of it. I have great faith in our ability to solve most technical problems if adequate resources, adequate market demand, adequate motivation are devoted to solving those problems.

Not to go on, but I think the first step in that is a panel like the one we have planned for FiltXPO, which is starting to recognize the existence of those challenges. I think this is the first step of that long and exciting journey.

Kevin Barry: Sustainability for single-use air filtration is a growing problem and concern. We’re continuing to consume resources, plastic, metal, and paper, which can be put back into use and consumed over and over and over again. As the United States and other countries are continuing to grow, from a home standpoint, new homes, new air conditioning units across the country, we’re going to be continuing to add to this problem. Is it the number one problem in the world? Don’t catch me ever saying that it’s the number one problem in the world, but it is something that we are all involved in on a daily basis, and my opinion is that as stewards of the Earth, we have a fiduciary duty to do what we can to leave the world in a better place than when we came to it. If we just make a whole bunch of money and throw a whole bunch of things into the trash, I don’t really believe we’re leaving the world a better place for the next generation coming forth. That’s why I believe that sustainability in our industry is necessary, and it’s necessary now.

I expect there will be some disagreement in our industry on how best to address the sustainability challenge. If there’s not disagreement, then the entire industry should already be doing these things. The industry’s not, so there’s going to be disagreement.

I hope, again, that everyone can show up to this panel at FiltXPO with the grace and space to listen and learn about something they may not know anything about. That’s what I hope I can contribute value to. I’m not going to try to tell anybody they have to do something or they have to do X, Y, or Z, or vote X, Y, or Z way, but again, there’s new things for everyone to learn every single day, and this industry has some opportunity to learn where in sustainability we can really drive the industry forward.

FiltXPO 2022 will present three days of provocative debates, with five panels of global industry experts who will share pivotal ideas aimed at uprooting traditional industry perceptions. For more information, visit filtxpo.com.

International Filtration News is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org), organizer of the FiltXPO exhibition and technical conference.