Irrigation water use and re-use in agriculture cycle around pretreatment and filtration

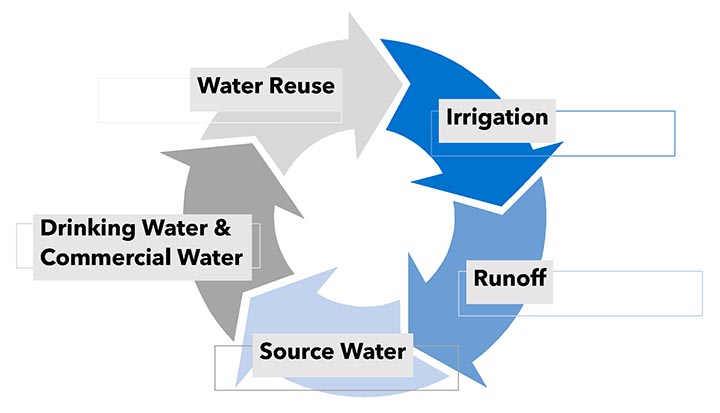

The water cycle tracks the movement of water from lakes, streams and oceans to the clouds and back again, linked by evaporation and precipitation in an endless, global circle. But there’s another kind of circularity that drives the world of agricultural irrigators and water professionals – the tumble of water through a cycle of use and re-use. Source water is diverted or pumped for irrigation, which runs off to streams or trickles through the soil to join groundwater, which is tapped for use as drinking or commercial water, which is treated for re-use or released back into streams or aquifers. And so, it continues.

In that cycle of water use, the driver isn’t the heat energy that propels the traditional water cycle. It’s filtration.

The success of any cycle is measured in its efficiency. There is local loss in the water use cycle to evaporation (of course, that water will fall into someone else’s cycle as rain that replenishes source water supplies). Still, within a parcel of water that stays in the circular path, retention is driven by the effectiveness of the filtration systems that advance water to the next step in the cycle. And that effectiveness is improved by protecting downstream filtration processes.

Global benefits

The term “circular economy” is widely used in Europe. It’s a phrase that describes a cycle of use, reuse, sharing, recycling and overall reduction of waste and consumption. Circularity in water can deliver many of the same benefits, notably in reducing energy, wastewater and infrastructure costs.

Pretreatment of water prior to filtration can reduce the costs of backflushing, cleaning or replacing filter media. That includes the energy and water that would otherwise be used for filter cleaning, as well as labor and materials costs for media replacement. Better pretreatment may even reduce the amount of filtration needed downstream, reducing the costs of filtration systems as well as the physical infrastructure – the concrete, steel, chemicals and maintenance – needed for further treatment.

Looking downstream to how treated water is utilized, any process that helps farmers create less runoff or leaching saves water and reduces the threat of pollution from the off-target movement of crop protection products or excess nutrients. In turn, lakes, streams, aquifers and other water is protected, easing its path as it goes around the circularity path on its way to reuse or release (setting it up to be someone else’s good-quality source water).

Venturi injectors also use the flow of water to create a vacuum that draws and blends oxygen into drip irrigation water, delivering an oxygen slurry to crop roots. The result is not only the ability to produce more crop per drop – making more productive use of every acre and input to increase yields – but also to allow farmers to “plow without a plow,” opening vegetables and other drip-irrigated crops to practices like reduced tillage and no-till. In turn, those practices reduce passes across the field, lowering diesel consumption and the emissions associated with tractor operations. They cut down on soil loss, and help protect soil structure.

A team of researchers at California State University, Fresno; Memorial University in Canada; and the University of the West Indies in Trinidad and Tobago documented shifts in the microbial community of soil in which Mazzei AirJection systems applied aerated irrigation water to the crop root zone through buried drip lines. The changes in the soil biota favored microbes known to fix nitrogen in the soil. That improves nitrogen use efficiency, reduces levels of leachable nitrate nitrogen in the soil, and cuts down on the production of nitrous oxide and NOx compounds.

Better irrigation

Improving irrigation through pretreatment of water makes irrigation systems more efficient and reliable in general through actions as simple as protecting emitters throughout drip and microirrigation systems. The result is improved distribution uniformity, leading to more efficient water utilization and higher-yielding crops.

Those benefits are evident in the field as well as in controlled environment agriculture such as greenhouses and vertical farms, where the extremely high value of the crops and the intensity of production systems amplify problems or improvements in irrigation systems. Indoor agriculture systems are also particularly susceptible to biofouling, which can impact emitters, drip lines and filtration systems and harbor pathogens such as Legionella. Biofouling can be controlled with oxygenation – or its high-powered cousin, ozonation – through venturi systems.

Iron and manganese

Where metals such as iron or manganese are present, pretreatment of source water is vital to protect downstream filtration systems.

In San Angelo, Texas, managers of the drinking water utility tapped deep groundwater during a drought and encountered water high in radium and iron. The utility decided on ion exchange to remove the radon, but the new ion exchange media would have to be protected from fouling by the iron in order for the system to work.

San Angelo selected the Mazzei GDT system, which aerates a sidestream using venturi injectors and a Pipeline Flash Reactor (PFR) to blend the treated sidestream effectively as it is reintroduced into the main flow.

Any entrained bubbles are separated from the flow in a degas separator, which directs undissolved gas through a relief valve, minimizing downstream problems with bubbles in filtration systems.

Contact with the dissolved oxygen quickly results in oxidation, which causes insoluble iron oxide particles to form in the stream in about 15 minutes. The particles are captured via media filtration and the pretreated water is then passed on to the ion exchange system to remove the radon – with longer filter runs, backwash water, and without breaking pressure.

In a similar situation, the city of White Rock, British Columbia, found that arsenic and manganese were reducing water quality and reducing the service life of its filter media to just weeks. Further, a meticulous program of computational fluid dynamics (CFR) modeling revealed an opportunity to reduce the ozone dose from the initial recommendation of 0.5-1.0 mg/l to 0.2 mg/l, saving cost, energy and plant footprint while eliminating the need for a chlorine system. The ozonation system helped White Rock’s utility achieve its objectives and get more from its media filtration system.

Eliminating gas pains

As in San Angelo, water utility managers in Wichita, Kansas, adopted Mazzei degas separators to protect downstream systems and water quality in the city’s 30 MGD aquifer storage and recovery (ASR) project. Wichita used an advanced oxidation process (AOP) to remove atrazine herbicide before treated water would be injected into the aquifer. Excess gas produced during the AOP process would bind in filters in the subsequent step of treatment. The utility installed six degas separators – at six feet in diameter by 16 feet tall, they had a footprint of just 160 square feet in total – and achieved 97% gas removal with minimal physical footprint and energy consumption.

Minimizing energy consumption was a key objective of an ozonation system in an ASR project in Monterey County, California, which had been installed to protect microfiltration and reverse osmosis filters downstream. There, utility managers sought a way to increase the ozone transfer efficiency of their system above 90% in a pipeline contactor operating at the relatively low pressure of 8.5 psig. The conventional way to approach the challenge would have been to raise the dose of ozone or increase the pressure in the contactor to 30 psig – both energy-intensive approaches.

Instead, they worked with Mazzei’s CFD modeling team to explore a more efficient approach. Ultimately, Mazzei designed a sidestream injection system returning to the main stream through two Pipeline Flash Reactors rather than one. The extra nozzles of the second Pipeline Flash Reactor created a significantly larger low-dosage mixing zone in the main stream, ramping up transfer efficiency to target levels at the lower pressure.

The two-PFR approach also provided more flexibility for utility staff to handle high turndown rates and adjust their ozonation strategy to optimize cost efficiency based on energy and wastewater quality.

Protecting BAF systems

Ozone can be highly effective at extending the service life of biologically active filtration (BAF) systems. By breaking up organic particles that increase biological oxygen demand (BOD), AOP systems with ozone prepare contaminants in water for digestion by BAF microbes. Organic particles interfere with light transmittance, so the same process can be utilized to enhance the efficacy of UV disinfection systems.

Pretreatment of water protects downstream filtration systems, improves systems from irrigation to BAF filtration, and delivers a wide range of environmental benefits from reduced energy consumption to lower emissions of greenhouse gases – and maintains the circularity of the water use/re-use cycle. Circularity that goes straight to the triple bottom line.