People spend up to 90 percent of their time indoors and indoor air can be two to five times, and even up to ten times, more polluted than outdoor air. The young, elderly, chronically ill, and those with respiratory

or cardiovascular disease are typically the ones most impacted by poor indoor air quality (IAQ). Risks from outdoor pollutants, such as wildfire smoke, and indoor pollutants, such as the SARS-CoV-2 virus responsible for the COVID-19 pandemic, are more pertinent than ever.

The primary purpose of heating, ventilation and air-conditioning (HVAC) systems is to provide the functions of heating and cooling for indoor spaces. An often-underappreciated aspect of HVAC systems that deserves examination is their ability to maintain healthy IAQ – which is achieved through effective air ventilation. Safe IAQ is becoming an increasingly important factor in determining the optimal methods for protecting human health from harmful indoor airborne particulates, while also minimizing energy use and CO2 emissions.

Beyond the simple replacement of indoor air with outdoor air through ventilation, air cleaning systems could also remove harmful airborne particulates such as wildfire smoke, bacteria, viruses, and VOCs. Metalmark developed a self-renewing air cleaning system that removes harmful airborne particulates, wildfire smoke, and a number of pathogens. The testing summarized here makes this new technology the first and only one to have been tested with a proven ventilation-effective efficiency method and rating.

The Connection Between Indoor Air Quality and Ventilation Effectiveness

Healthy and safe indoor air quality (IAQ or indoor environmental quality) is principally determined based on no harmful concentrations of known contaminants to human occupants. Ventilation is the dilution of air pollutants through mechanical, nonmechanical (natural), or hybrid (mixed-mode) means by supplying outdoor air into the indoor space. However, dilution alone is an insufficient solution to mitigating pollution or infectious disease exposure. The quality of the air is key, as opposed to a general focus on the quantity or volume of air flow.

Another important but oftentimes overlooked factor is the exhaust for the removal of contaminants. As an illustration, in the case of infectious aerosols, a study showed that high ventilation rates (23 ACH) only marginally impacted levels of bioaerosol concentrations and respiratory disease transmission rates than low rates (1.3 ACH), using ferrets as the study subjects (ferrets are commonly used as models for influenza virus transmission studies).

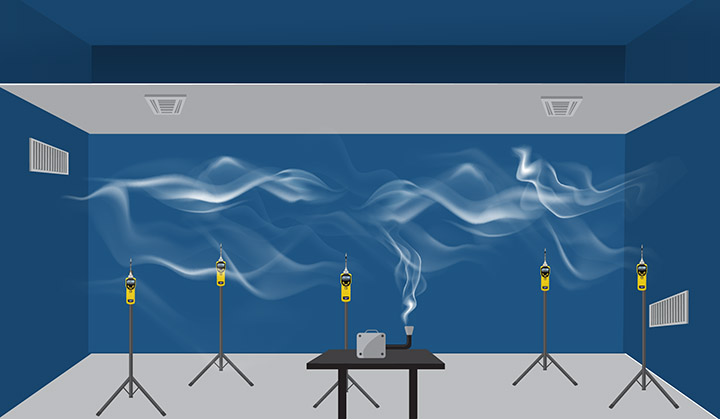

Figure 1. Illustrations of test setup (not exact or to scale): a) control with HVAC system ventilation only;

b) operating Metalmark air cleaner in addition to HVAC system ventilation. Particle doses were introduced

in the center of the space and measurements were taken at 5 points of the space. Space size: 750 ft2 x 11 ft.

Metalmark developed a self-renewing air cleaning system that removes harmful airborne particulates, wildfire smoke, and a number of pathogens.

ASHRAE Standard 62.1, Ventilation for Acceptable Indoor Air Quality, provides the minimum ventilation rates, along with other measures, that are set to provide IAQ levels acceptable to human occupants to minimize adverse health effects. Simple mechanical ventilation systems typically work by using fans that are installed either directly in windows or walls or in HVAC air ducts, to drive ventilation. Most commercial HVAC systems accomplish this through utilizing air conditioning or air handling units. These ventilation systems are defined in terms of air flow rates, which may be numerically converted to air changes per hour (ACH) – the ratio of the volumetric rate of air removal through vents or ducts to the volume of the enclosed space – depending on the volume of space served. ACH is calculated by taking the volume of air in cubic feet per minute (CFM) delivered to or exhausted from the indoor space and multiplying that by 60 (minutes/hour), then dividing that number by the room’s volume in cubic feet. While ventilation requirements are just one element of IAQ, it is a standard metric for comparing the ACH provided by different air cleaning solutions.

A number of factors lead to the under-performance of typical HVAC systems in achieving the goal of proper ventilation. In the case of ensuring safe indoor air quality, the most understated factor is air flow patterns, as most HVAC designs only consider temperature-related flow rates and patterns in a given space. Along these same lines, standalone or portable air cleaners (PAC) or purifiers suffer from a similar problem. In industry and general usage, air purification refers to the cleaning and recirculation of the same air, whereas air ventilation is assumed to push old air out of a physical space and bring filtered, cleaned air into it.

Evaluating the efficacy of a PAC and similar solutions should include not only unit-level air purification capabilities, but also the ventilation equivalent, or effectiveness, assuming clean outdoor air conditions. No air purifiers on the market today have been tested for their space-relevant airflow patterns, which are central to achieving ventilation effectiveness, especially in a space larger than that of the typical air chambers used in industry testing.

Ventilation Effectiveness (VEFF) refers to how well the air is circulated throughout a space leading to the removal of contaminants. It is an appropriate measurement for determining the overall effectiveness of an HVAC system design or air cleaning system. Traditional HVAC systems often fall short of the desired results for ventilation effectiveness. One reason is that the vast majority of the industry relies on ASHRAE Standard 62.1 Ventilation Rate Procedure’s (VRP) prescriptive ventilation flow rates, which are estimated based on a space’s usage type, its square footage, and the expected maximum number of occupants, to size HVAC equipment and determine ventilation flow rates, rather than IAQ considerations.

The same ASHRAE Standard 62.1 also provides the Indoor Air Quality Procedure (IAQP), which is more IAQ targets-driven yet also has its deficiencies. Based on idealized ACH measurement comparisons, certain air cleaning technologies may influence air flow patterns more beneficially, thus resulting in greater ventilation effectiveness than the standard HVAC system or provide means of increasing the effective ventilation efficiency of the standard HVAC system.

When the Ventilation Effectiveness of Standard HVAC Systems and Air Cleaners Falls Short

Traditional HVAC systems are primarily designed for temperature control and consistency and work contrary to the more agile and responsive needs of effective indoor air cleaning. Furthermore, HVAC systems are designed based on the well-mixed room model, which assumes that the concentration of pollutants in an enclosed space should be spatially uniform, an assumption that suits the goals of temperature management.

This model does not take into account the reality that indoor spaces are rarely well mixed, and airborne pollutants such as pathogens can stagnate and distribute unevenly due to a variety of factors, such as the type of airflow pattern, ventilation strategy, locations of sources, and fresh air inflow. Moreover, ventilation effectiveness can be negatively impacted by the blockage of airflow or flow vent direction – leading to a higher intake of contaminated air. When the flow pattern is not properly set up, it can significantly reduce ventilation effectiveness and make the HVAC air cleaning regime ineffective as a whole. Due to many such issues, HVAC systems may fail to create an airflow pattern that provides adequate ventilation effectiveness, rendering them less effective at improving IAQ than theoretically expected or model predicted.

One of the specifications provided for standalone or portable air purifiers (also referred to as air cleaners) is the Clean Air Delivery Rate (CADR), which is a standard defined by the Association of Home Appliance Manufacturers (AHAM). The CADR measures an air cleaner’s effectiveness, frequently tested with three separate analytes to represent common indoor pollutant categories: dust, pollen, and tobacco smoke. CADR numbers are based on the percentages of particles removed, space volume, and the volume of clean air produced per minute. According to the U.S. EPA, CADR is “the most helpful parameter for understanding the effectiveness of portable air cleaners.”

In general, the higher the CADR number, the better the cleaner’s ability to filter for each specific pollutant type. A simple function can be applied to transform the CADR value into theoretical ACHs. However, such tests are conducted in small-volume air chambers with the unit typically centered in the space, and ignore the role of airflow patterns created by the unit in a real-world environment. Thus, the direct translation to ACHs is often unrepresentative of effective ACH equivalence.

Testing the Ventilation Effectiveness of the Metalmark Self-Renewing Air Cleaner

Employing cutting-edge science and engineering, Metalmark designed a self-renewing air cleaner that breaks down airborne contaminants captured on the filter to reduce the hassle of frequent filter replacements. As an independent third party and global leader in airflow management for critical indoor spaces and mixed-use facilities, 3Flow developed a methodology to test the ventilation effectiveness of air cleaners and conducted the test on the Metalmark system.

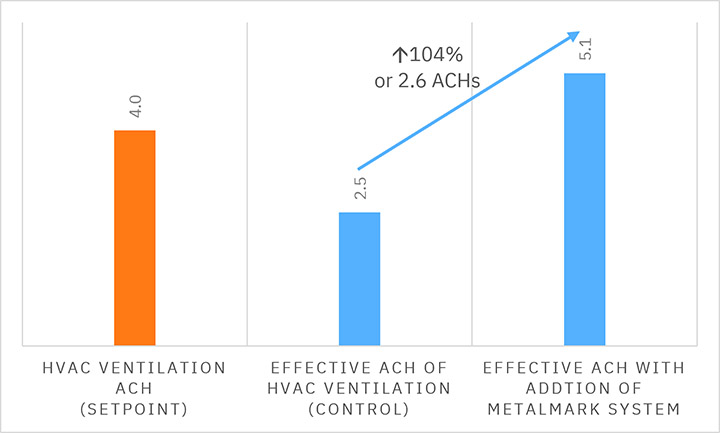

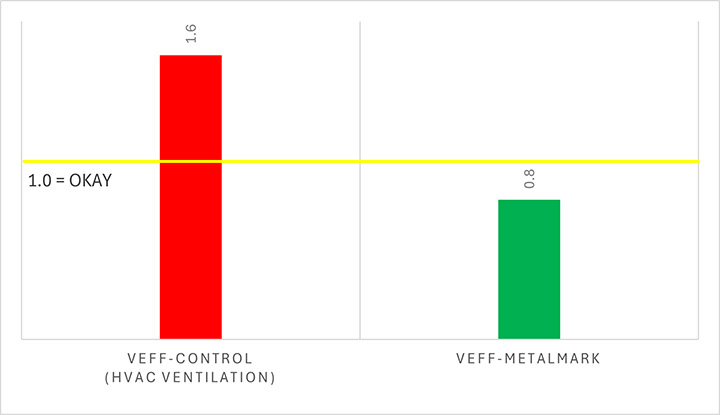

Figure 2. A comparison between promoted effective air change rate under Metalmark filtration conditions and control conditions: an improvement of 104% was observed. The test space was maintained at HVAC set point of 4 ACH.

In the test, 3Flow compared the gas and particle removal efficiency and ventilation effectiveness of the Metalmark air cleaner, compared to that of the baseline HVAC ventilation system. The tests were conducted in a 750-square-foot room with an 11-foot ceiling (8,250 ft3), which is representative of the space volumes of Metalmark system’s intended applications. A series of 60-minute tests were performed to establish the baseline room conditions and compare with the metrics achieved during various operational modes, with different installation orientations of the Metalmark system, as well as using two dissimilar diffuser designs.

During the tests, particles and tracer gas were generated using a TSI 9306 atomizer filled with 0.1 percent saline isopropanol (IPA) solution under compressed air conditions. A set of sensors were installed to collect the data for generation and decay behaviors of the tracer gas and particles. The test space was undisturbed by human presence or other activities during the test to maintain the airflow patterns induced solely by the Metalmark unit and in-room ventilation elements while limiting any external factors. The room airflow was maintained at 4 ACH using the HVAC system.

The following variables were measured in the study:

- Airflow at minimum, medium, and maximum operational modes of the Metalmark air cleaner.

- Particle Removal Efficiency expressed in terms of particle counts per cubic foot for the following particle sizes: 0.3μm, 1.0μm and 5.0μm.

- Ventilation Effectiveness (VEFF) Rating for IPA = Measured dose/Theoretical dose.

- Effective ACH defined as the ratio of room ACH to VEFF rating.

- Average IPA/tracer concentration.

The effective ACH of the Metalmark air cleaner was established based on data collected for the above.

Study Results

The tests demonstrated a significantly greater reduction of particle concentrations from the use of the Metalmark air cleaner compared to the control conditions of operating the HVAC ventilation system. Operation of the Metalmark system at maximum mode swept particles from the point of generation towards the inlet, resulting in higher particle removal potential compared to the minimum mode. Different orientations, diffuser designs, and system air cleaning levels all impacted the pollutant removal efficiency. Taken altogether, the Metalmark system boosted ventilation effectiveness by 51% higher than the baseline conditions, resulting in higher particle removal rates and enhanced air cleaning.

This study reveals that the airflow pattern created by an air cleaning system in the context of a room space is directly correlated with the air cleaning outcome. As shown in Figure 2, even though an HVAC system could theoretically change the air in the room four times per hour based on its flow rates, the actual efficacy of its air cleaning is, in fact, pronouncedly lower than the theoretical value due to the non-well-mixed nature of the space. In other words, simply pushing more outdoor air volume into a space does not mean higher efficiency or degree of air cleaning.

It turns out that there are many factors involved and airflow patterns are important to achieving the desired air cleaning objectives. Taking into account the VEFF rating for the test space, the Metalmark system improved the effective ACH of the space from 2.48 (control) to 5.06 (Metalmark), promoting the effectiveness of HVAC set point of 4 ACH in the space. In simple terms, it could add 2.6 effective ACHs at max level of air cleaning to a similar room space to serve as either a supplement or partial substitute to the existing ventilation levels. This is particularly relevant in light of ASHRAE’s Standard 241 for achieving adequate airborne pathogen removal levels, as well as in consideration of poor outdoor air quality and the requirement for energy and climate footprint reductions.

Protecting Human Health

Indoor air quality is highly impactful on human health and well-being. As growing threats to air quality from outdoor sources, such as wildfire smoke, and indoor sources, such as airborne viruses, continue to rise, it is critical for commercial buildings to have proper ventilation and air cleaning systems in place.

Most commercial building spaces, for example, schools, hospitals, and offices, that utilize traditional HVAC systems are operating sub-optimally, especially given the increasing need for better indoor air quality. They would benefit from upgrading their air cleaning systems to one with higher ventilation effectiveness. This requires looking beyond theoretical air change or efficiency values, toward solutions with proven ventilation equivalent efficiencies. This means that air cleaning technologies need to not only filter contaminants that enter the core units but also improve ventilation effectiveness as demonstrated in this study.

References:

- [U.S. EPA] Environmental Protection Agency. 2024. Indoor Air Quality: What are the trends in indoor air quality and their effects on human health? Accessed at: https://www.epa.gov/report-environment/indoor-air-quality. Washington, D.C.: Environmental Protection Agency.

- [OSHA] Occupational Safety and Health Administration. 2024. Indoor Air Quality: Frequently Asked Questions. Accessed at: https://www.osha.gov/indoor-air-quality/faqs. Washington, D.C.: U.S. Department of Labor.

- Rockey, Nichole et al. “Ventilation Does Not Affect Influenza Virus Transmission Efficiency In A Ferret Playpen Setup.” bioRxiv 2023.12.26.573248; doi: https://doi.org/10.1101/2023.12.26.573248

- [ASHRAE] American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2024. ANSI/ASHRAE Standard 62.1-2022, Ventilation and Acceptable Indoor Air Quality. Accessed at: https://www.ashrae.org/technical-resources/bookstore/standards-62-1-62-2

- Atkinson, J., Chartier, Y., Pessoa-Silva, CL., et al. (2009). Natural Ventilation for Infection Control in Health-Care Settings. Concepts and types of ventilation. Geneva: World Health Organization. Accessed at: https://www.ncbi.nlm.nih.gov/books/NBK143277/

- Zhang, Z., Capecelatro, J., and Maki, K. (2021). On the utility of a well-mixed model for predicting disease transmission on an urban bus. AIP. Accessed at https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8404159/

- Mullick, A., Kumaraswamy, G., Mehra, S., Murallidharan, J., Kumar, V., and Sinha, K. (2023). Is well-mixed model of an indoor space with ceiling fans valid for studying pathogen transmission? Physics of Fluid. Accessed at: https://pubs.aip.org/aip/pof/article/35/10/107131/2918208/Is-well-mixed-model-of-an-indoor-space-with

- [AHAM] Association of Home Appliance Manufacturers. 2024. Air Filtration Standards. Accessed at: https://ahamverifide.org/ahams-air-filtration-standards/

- [AHAM] Association of Home Appliance Manufacturers. 2020. Indoor Air Quality Is an Essential Part of a Healthy Home. Accessed at: https://www.aham.org/AHAM/News/Latest_News/CADR_

Indoor_Air.aspx?WebsiteKey=c0a5e5a1-ea1c-42f1-9b84-d62256c16ea2 - [ASHRAE] American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2024. ASHRAE Standard 241, Control of Infectious Aerosols. Accessed at: https://www.ashrae.org/technical-resources/bookstore/ashrae-standard-241-control-of-infectious-aerosols