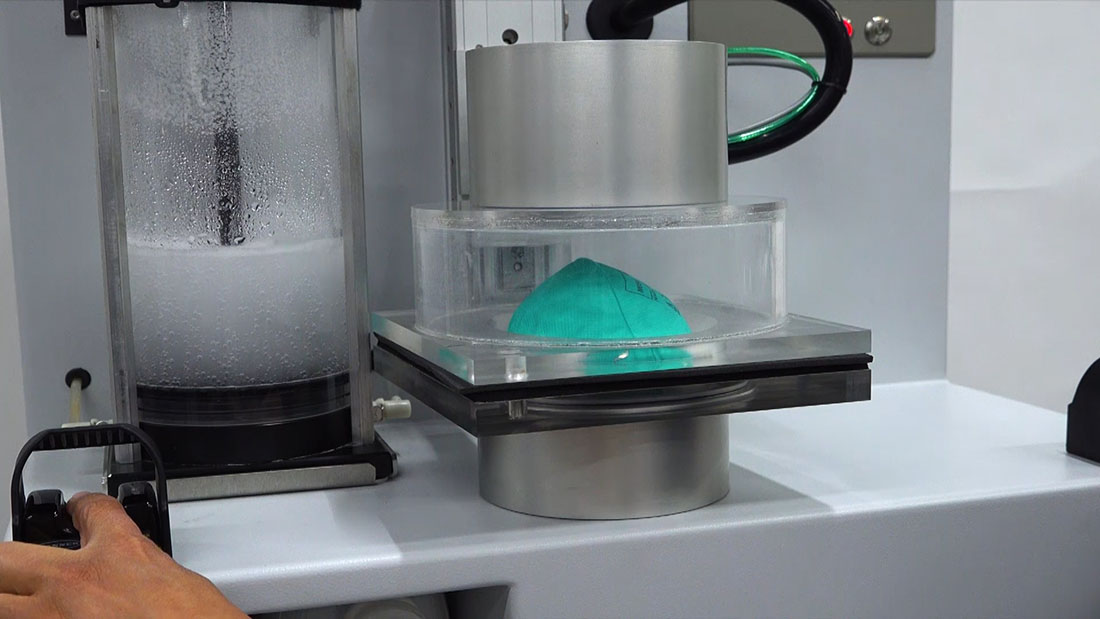

Early on in the COVID-19 pandemic, INDA, The Association of the Nonwoven Fabrics Industry, was hard at work connecting nonwovens producers with medical facemask, surgical gown and wet wipe manufacturers. Electrostatically charged meltblown media was especially critical, as it is the workhorse of N95-rated facemasks here in the U.S., as well as other high-performance masks around the world.

There was a tremendous amount of commercial activity that took place at the beginning of the pandemic due to the fact that major suppliers of facemask materials were located in Asia, and they chose to keep those raw material supplies to support the needs in their own countries.

While the world scrambled to find meltblown supply, questions started to follow about how long it would take to build new equipment or if there were alternatives to meltblown to meet the need.

Major manufacturers of meltblown equipment found ways to shave months off of building and installing new assets, but the supply was still six months to a year away, and healthcare providers were struggling to find anything they could use for respiratory protection – even if it wasn’t high performance. Likewise, the general public was turning to anything it could find that would make for a passable facemask, from handkerchiefs to homemade cloth facemasks and other options.

Responding to a dire need

It quickly became apparent that we needed a better option. While non-healthcare workers and the general public may not require N95-level masks, they certainly deserved something more effective than a piece of cloth.

As such, a coalition of filter media manufacturers was assembled to determine what alternative media may be available and how they could perform. Many media were identified as a better option than what was currently being employed, and millions of yards were available to be put to the task of producing facemask material. However, there was no way to validate these technologies.

This is when, what we call here at INDA, Project N80, was conceived. The idea was to provide an alternative material option for facemasks that wasn’t quite to the level of an N95 (or similar) but could provide filtration efficiency for the user in the range of 80% for virus particles, which far exceeds the current options being employed by the general public and many workers.

On April 16, 2020, I put a call in to the deputy director of the National Personal Protective Technology Laboratory (NIOSH), Jonathan Szalajda, to determine if there might be an opportunity to develop a new specification that would tap into the vast amount of other nonwoven filter media that could provide a new source of facemask protection; albeit at lower filtration rates than the high-efficiency N95/KN95/FFP2 mask types commonly employed in healthcare scenarios.

It quickly became apparent that we needed a better option. While non-healthcare workers and the general public may not need N95-level masks, they certainly needed something more effective than a piece of cloth.

NIOSH was quick to respond, and a meeting with some of their top thought leaders was scheduled. It was determined that the media under consideration would not be able to meet the respiratory levels of which NIOSH was responsible, and ASTM would be the best alternative to conceptualize and draft a new method. Since Jonathan was not only a deputy director at NIOSH, but also the chair of the ASTM respiratory committee, we were able to move the initiative forward in relatively short order.

ASTM is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems and services. ASTM has over 10,000 standards, developed within committees, which are formed as needed. These committees are voluntary and are initiated and comprised of members.

The members of the newly formed committee responsible for the N80 project were from all parts of the supply chain, including users, producers, consumers and even those with general interest who wanted to help provide better respiratory protection to the general public and non-healthcare workers.

Developing the specification

Once the technical committee and working group was formed, the hard work of developing a new-to-the-world specification for barrier face coverings began. This specification had to distinguish itself from other respiratory protection standards, in that it was establishing a method and performance criteria for facemask materials for non-healthcare/non-first responder workers and the general public.

Through the vast experience of the committee members, we were able to pull the right people together to develop something new that would utilize test methods that were proven over decades. Meetings were organized three times a week and on weekends to draft and iron out all the details, and in the end ASTM 3502-21 was the result of over a 100 hours of Zoom meetings with upwards of 70 people involved at one time or another.

With the new standard in place, the story took a turn when an executive order on protecting worker health and safety was initiated by U.S. President Joe Biden on January 21st. This potential game changer considers whether an emergency temporary standard on COVID-19, including with respect to masks in the workplace, is necessary, and if so calls for this standard to be issued on March 15, 2021.

Bonus ’Tech Talk’ Video

Learn More @ inda.org/education!

There are several technologies, both woven and nonwoven, that meet the ASTM 3502-21 specification, but there are fewer that meet the guidance recommendations that were sent to OSHA. There are two levels of performance that were recommended by the expert panel – one is > 50% efficiency for workers with lower exposure to risks and >80% efficiency for workers with higher exposure to risks in the workplace.

Both of these performance levels have a <15 mm of water airflow resistance. These high tolerances can be met by a number of nonwoven technologies, while reserving the supply of material for N95/KN95/FFP2 masks for those who most need them, primarily healthcare workers and first responders.

The emergence of recommendation for an 80% efficiency mask standard could really impact the competitive landscape for material suppliers and facemask manufacturers in many ways. This opens the door for some standard nonwoven products, including needlepunch, carded and wetlaid technologies, and it also fosters product development efforts to create new materials over time that can meet these needs in new ways. Facemask manufacturers will be impacted by these new materials, with increased production speeds for single-layer materials that meet the requirements, as well as a simplified and diversified the supply chain.

Lessons learned

There have been many lessons learned through the development of this new specification in terms of offering better protection for the next pandemic. The world was caught without proper personal protective equipment at the outset of COVID-19, and we had to utilize substandard products or reuse disposables in unintended ways.

Looking back at the last 12 months, we’ve learned a lot about how viruses behave in aerosol, and how they differ from bacteria. In filtration the size of the particle matters, and never has that been more apparent. The ASTM 3502-21 specification is not designed for a medical mask or a respirator but focuses on something brand new that wasn’t addressed prior to the pandemic. It provides particle filtration protection at the virus level for non-healthcare workers and the general public.

This new specification also provides new design opportunities to differentiate, create competitive advantages and build brands. There are many companies that have tested their masks to ASTM 3502-21, and several companies that have been waiting for months to have their product tested to N95 standards that have looked to this specification as a way to get their products to market more quickly and efficiently. With this standard, testing is faster and less expensive, thus providing an opportunity to offer protection that is measurable in an environment where people are scrambling and using products that have no validation of performance.

The ASTM 3502-21 can be found on the ASTM website at astm.org/COVID-19/. ASTM International is providing no-cost public access to important ASTM standards used in the production and testing of personal protective equipment. INDA has also produced a webinar that discusses this new standard in depth, and it is available on our website at inda.org.

I would like to thank everyone in the filtration industry who pulled together to make the ASTM 3502-21 specification happen. This effort is an example of the best the filtration industry has to offer.

As director of education and technical affairs, Chris presents regular training related to nonwovens and filter media from INDA’s headquarters in Cary, NC. For more information about upcoming training opportunities, visit inda.org/education.

* International Filtration News is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).